ii

SAFETY PRECAUTIONS

Maintenance

Individual safety

Gases and fumes

Fire

Noise

Protection goggle

*

Often check the insulation and connection good state of apparatus and electrical

accessories

:

taps, appliance cords, coatings, switch, extension cords, etc.

﹡

Maintenance and repair of insulating coatings operations are very important.

﹡

Do repair with a specialist or better replace defective accessories.

﹡

Check regularly the right adjustment and the non-heating of electrical

connections.

﹡

The operator must be dressed and protected in relation with his work.

﹡

Avoid contacting metal parts connected or accidentally connected.

﹡

Wear leather gloves with gauntlet.

﹡

Safety clothes: gloves, apron, safety shoes protect the operator and his

assistants against burns of hot parts, projections and slag.

﹡

Gases and fumes produced during the plasma cutting or welding process can be

dangerous and hazardous to your health.

﹡

Ventilation must be adequate to remove gases and fumes during operation.

﹡

Keep all fumes and gases from the breathing area.

﹡

Use an air supplied respirator if ventilation is not adequate to remove all fumes

and gases.

﹡

Oil or grease in the presence of oxygen may ignite and burn violently. Keep

cylinders, valves, couplings, regulators, hoses, and other apparatus clean and

free from oil and grease. Oxygen cylinders and apparatus should not be handled

with oily hands or gloves. Do not allow an oxygen stream to contact oily or greasy

surfaces.

﹡

Do not use oxygen as a substitute for compressed air.

﹡

Fire can be caused by hot slag and sparks.

﹡

Remove combustibles from working area or provide a fire watch.

﹡

Do not cut containers that have held combustibles. Remove all flammable and

combustible materials in the operating area that may be ignited by sparks.

﹡

Noise can cause permanent hearing loss.

﹡

Wear proper protective ear muffs or plugs.

﹡

Make sure others in the operating are protected from noise.

﹡

Welding radiation may cause permanent sight damage

Eyes protection goggle recommended

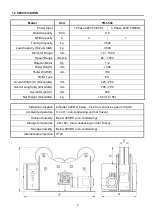

Summary of Contents for TR-3504

Page 2: ......

Page 8: ...T T TH H HI I IS S S P P PA A AG G GE E E I I IS S S B B BL L LA A AN N NK K K ...

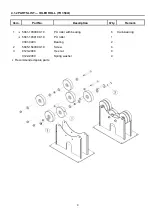

Page 11: ...3 1 3 INSTALLATION Power Roll Idler Roll ...

Page 13: ...5 2 1 REMOTE CONTROL INSTRUCTION ...

Page 19: ...11 T T TH H HI I IS S S P P PA A AG G GE E E I I IS S S B B BL L LA A AN N NK K K ...

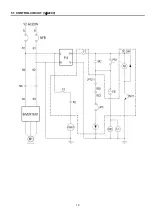

Page 20: ...12 5 1 CONTROL CIRCUIT 1ψ220V ...

Page 21: ...13 5 1 CONTROL CIRCUIT 3ψ380V 415V 460V ...

Page 22: ...14 5 1 CONTROL CIRCUIT REMOTE CONTROL ...

Page 23: ...15 5 2 CONTROL SYSTEM BOX 1ψ220V 3ψ380V 460V ...

Page 26: ...18 APPENDIX B CIRCUIT AC220V 1 PHASE ...

Page 27: ...19 APPENDIX B CIRCUIT AC380 415V 460V 3 PHASE ...