Adjustments

11 / 18

5450.0004

V3

GB

4.1.4

Fork sleeves (optional)

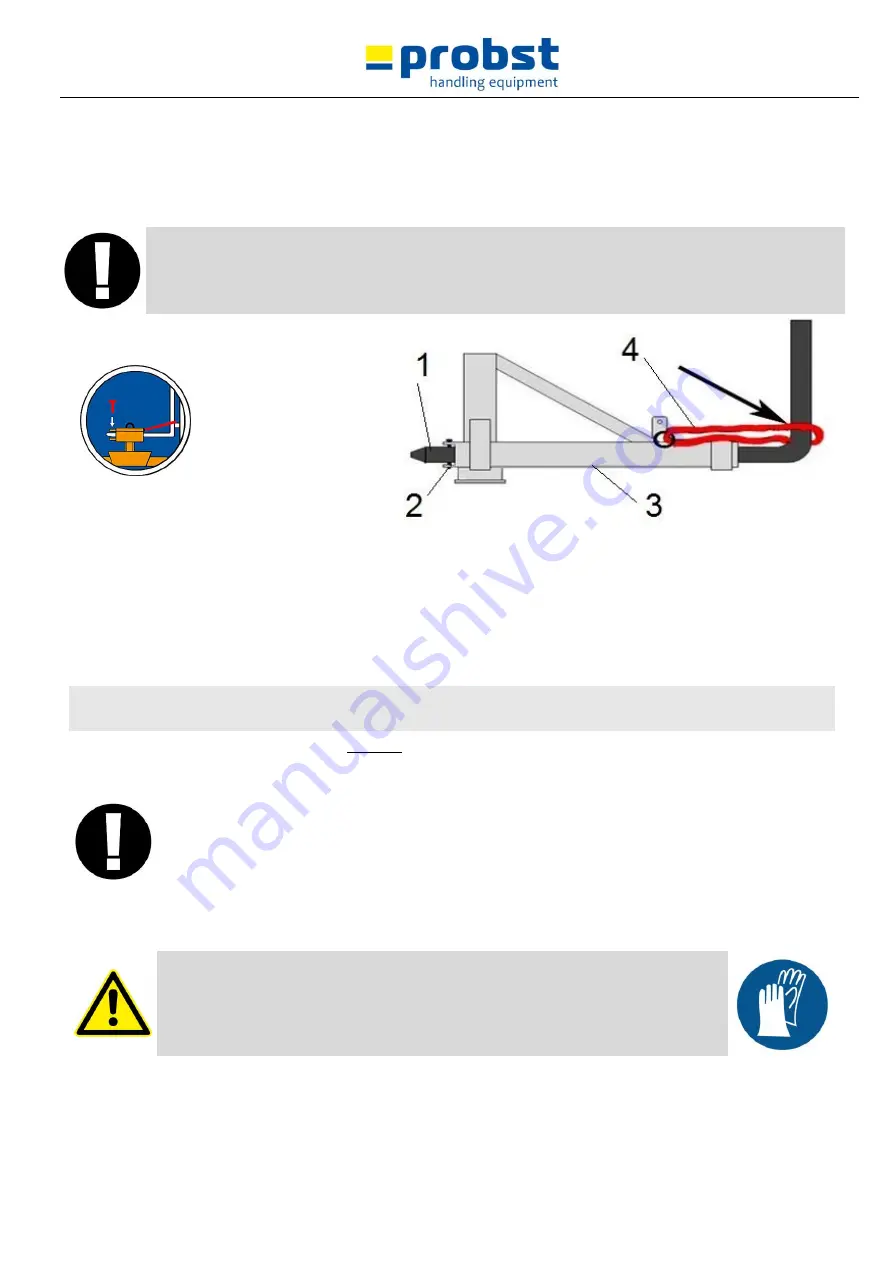

To establish a mechanical connection between the fork lift truck and the fork sleeves you have to put the

forks into the fork sleeves and fix it with the locking bolt or with a chain/rope, connected to the eyelet on the

fork sleeves and the lift frame.

It is definitely necessary to establish this connection. Otherwise the device could slide form the forks.

DANGER OF ACCIDENTS!

1 Fork (of fork lift truck)

2 locking bolt

3 Fork sleeve

4 Chain/rope

5

Adjustments

5.1

Adjustment of the gripping range

By changing the gripping range, the RG-8/40 device can be used to grip goods of different sizes (concrete pipes).

Before a material to be gripped can be lifted and moved, the corresponding gripping range and the height-

adjustable support must be set.

•

The gripping range must never be set on both sides at the same time.

Always set the gripping range first on one side and then on the other.

•

Pull spring bolt (1) upwards and turn by 180°.

•

Move the rectangular tube (2) until the gripping range is approx. 5 cm larger than the material to be

gripped.

•

Pull the spring bolt (1) upwards again and turn it by 180°.

•

Push the rectangular tube (2) back and forth until the spring bolt (1) engages in the corresponding

hole.

•

Gripper range adjustment must generally be

symmetrical

.

This means that the same adjustment hole must be used for both rectangular tubes.

•

Take care when adjusting the gripping range. Risk of injury to hands!

Use protective gloves.

→