MAINTENANCE

COMANCHE 86038890 03/20/07

4-3

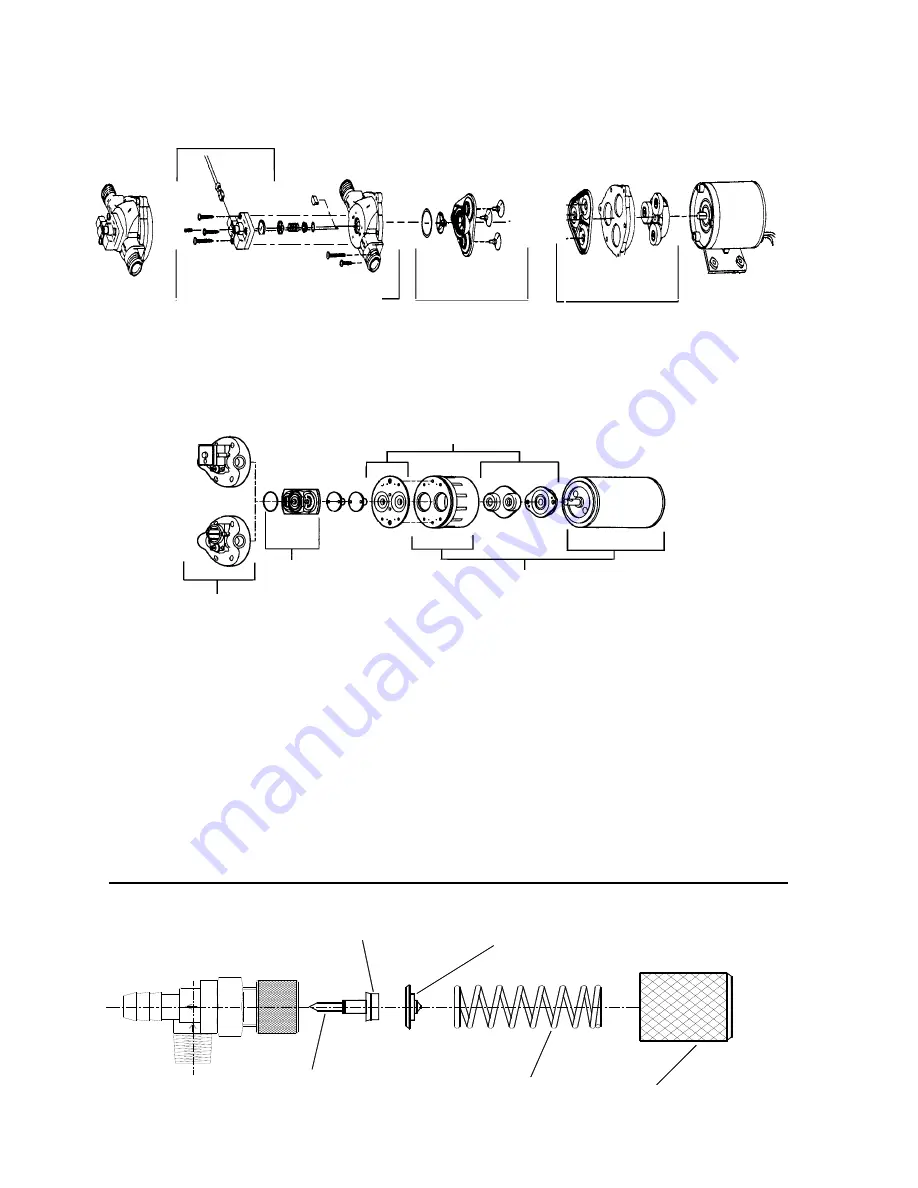

PRESSURE REGULATOR

For best results with the pressure regulator, we recommend that you clean and lubricate

the piston and u-cup with Superlube lubricant monthly or when pressure drop seems excessive.

1. Turn unit off before lubricating.

2. Remove cap, spring and spring retainer plate.

3. With fingertips remove piston and u-cup.

4. Wipe piston and u-cup clean of any film or scale.

5. Lubricate the piston and u-cup with Superlube.

6. Reassemble

regulator.

7. With pump ON, re-adjust pressure regulator for normal operation.

LUBRICATE U-CUP WITH SUPERLUBE MONTHLY.

P IS T O N

S P R IN G R E T A IN E R P L A T E

S P R IN G

C A P

U - C U P

IN

O U T

( G O L D - 1 2 5 P S I)

Bypass Valve Asm

86258830

PRV NO. 84161

Diaphragm

86235100

PRV NO. 29206

Pump Head Replacement

86251040

PRV NO. 65187

86161980 - PRV NO. 250-67

Switch Asm

PUMP REPLACEMENT PARTS FOR SHURFLO 100PSI (86201430 – PRV NO. 250-64A)

PUMP REPLACEMENT PARTS FOR FLOJET 100 PSI (86251110 – PRV NO. 65219)

86255109

PRV NO. 65204

PUMP HEAD

DIAPHRAGM

86235120

PRV NO. 29219

86258860

PRV NO. 84166

VALVE ASM

86247360

PRV NO. 53245

MOTOR