49

Maintenance

Vacuum Pump Drive Belts

To tighten the vacuum pump belts:

1.

Loosen the four bolts that hold the adjusting plate

to the frame and the 2 bolts at the back of the belt

guard.

2.

Turn the adjusting bolts until the proper belt tension

is achieved (1/4" deflection in the center of the belt,

halfway between the pulleys).

3.

Retighten all bolts previously loosened.

NOTE: When adjusting belt tension, make certain

that the engine shaft and vacuum pump shaft remain

parallel, and the belt tension is equal on both belts.

4.

Check belt alignment with straightedge.

Make certain that when you re-torque these screws,

that you use a clockwise pattern and continue until

proper torque is achieved.

S'assurer, au moment de resserrer ces vis,

d'utiliser un mouvement de rotation dans le sens

des aiguilles d'une montre et de continuer jusqu'à

ce que le couple souhaité soit atteint.

5.

Check for pulley groove wear, clean belts and

pulley grooves, check for worn belts, proper belt

tension, and pulley alignment after the first 25

hours and then again at 100 hours.

Check for belt ride in the groove.

Solution Pump

Refer to the Solution Pump Operation and Service

Manual for specific instructions.

1.

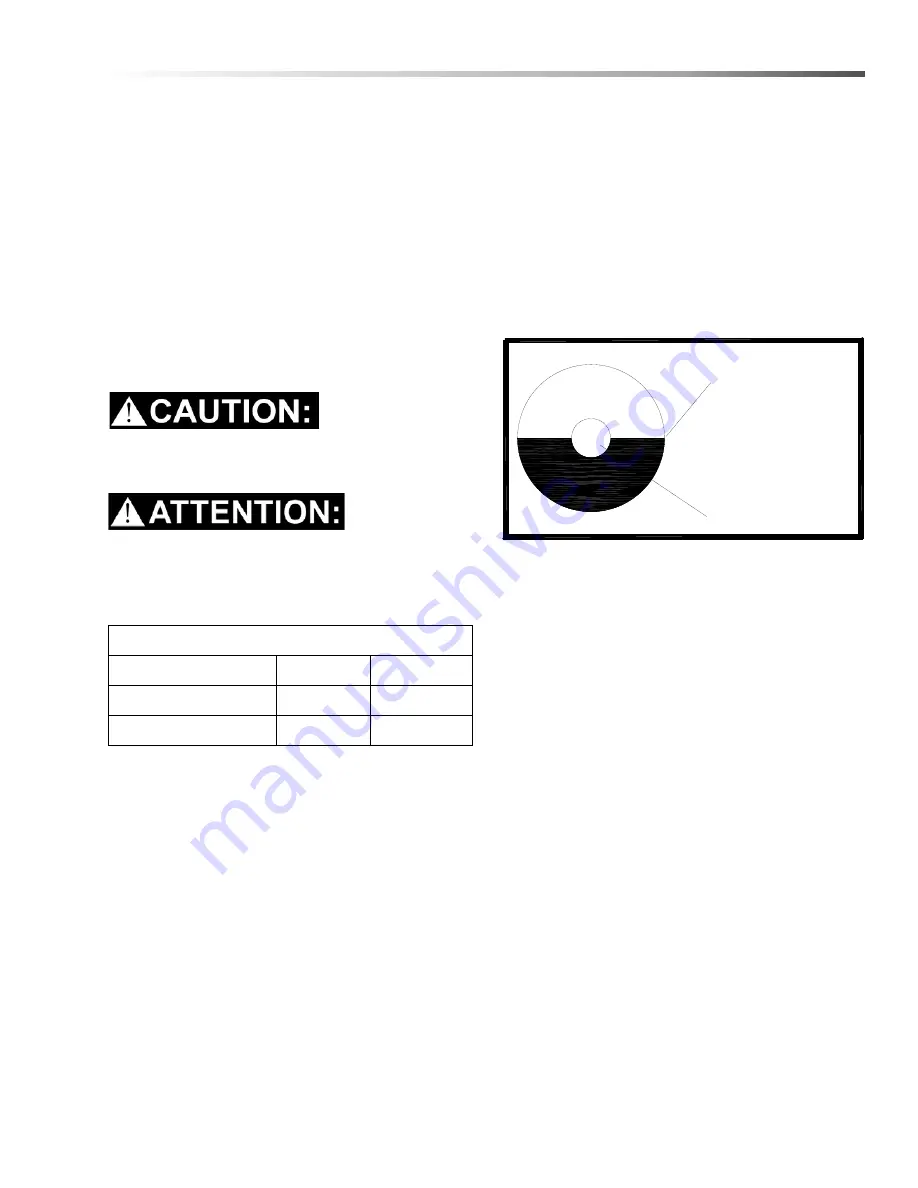

Check the crankcase oil level daily to assure the

proper level. Use the illustration as a guide when

checking the oil level. If the level has dropped,

check for the source of leakage and repair.

2.

Remove yellow filler cap with attached dipstick. Oil

level should be between marks on the dipstick or

use the sight glass located on the non-shaft side of

the pump.

3.

Change the crankcase oil with GP Pump

Crankcase Oil, after the first 50 hours of operation.

Drain and refill the crankcase oil with General

Pump Crankcase Oil every 500 hours thereafter.

Oil capacity is 40.6 ounces.

TORQUE VALUES

COMPONENT

INCH/LBS

FOOT/LBS

Engine pulley

360

30

Vacuum pump hub

300

25

RED DOT

OIL LEVEL

WITH UNIT

STOPPED &

ON LEVEL

GROUND

86411100 Manual Operators - Everest E-Idle Prochem