Summary of Contents for Priority ManufacturingSamurai

Page 17: ...4 6 THIS PAGE LEFT BLANK INTENTIONALLY...

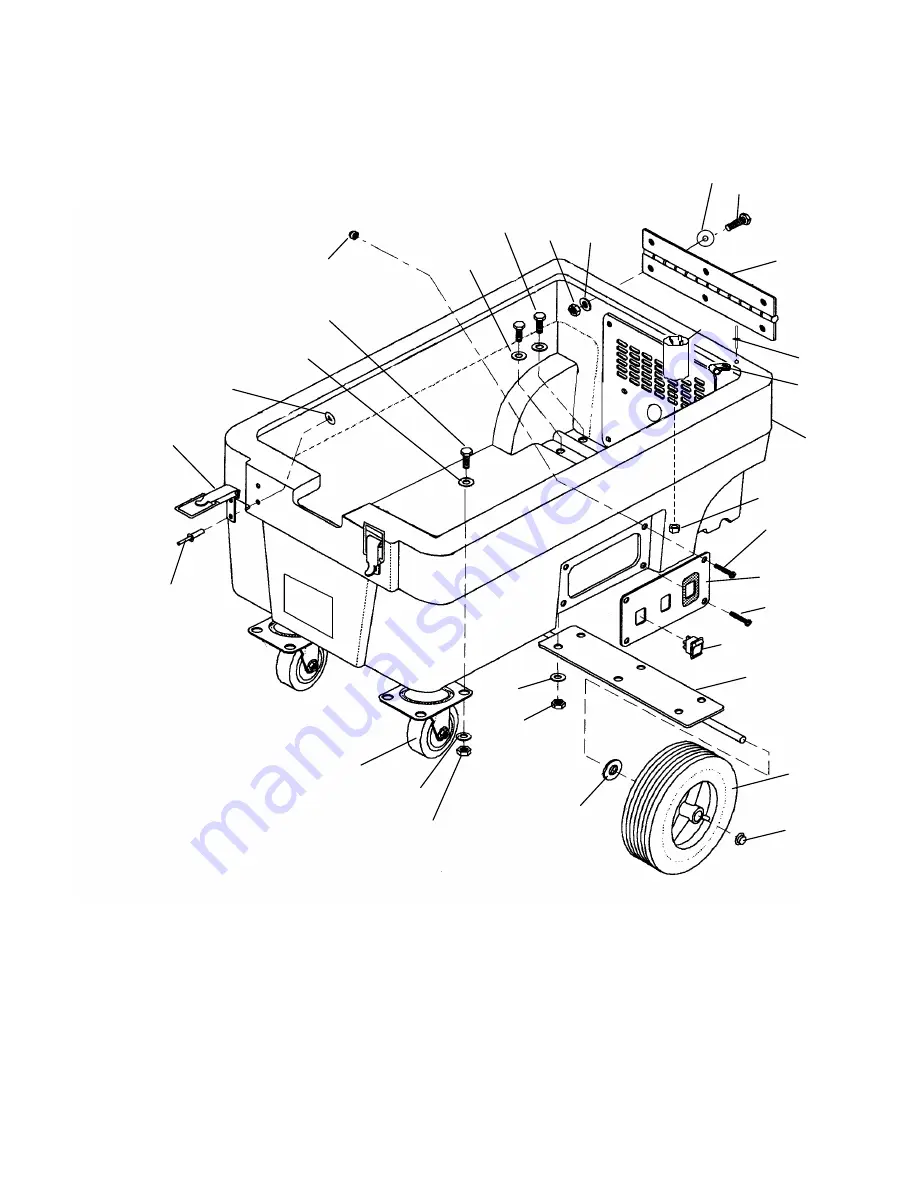

Page 18: ...BASE GROUP 5 1 3 2 20 19 18 17 16 15 14 13 12 11 10 9 8 3 8 3 7 6 5 4 3 2 1 3 2 15 3 21 22...

Page 20: ...LABEL STRAP GROUP 5 3 1 2 4 3...

Page 24: ...RECOVERY TANK GROUP 5 7 1 2 9 4 5 3 6 7 8 11 12 13 14 15 16 3...

Page 26: ...SOLUTION TANK GROUP 5 9 1 2 3 4 5 6 7 8 9 10 11 12 13 14...

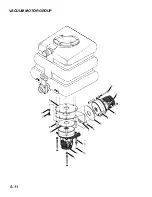

Page 28: ...VACUUM MOTOR GROUP 5 11 1 2 3 4 5 1 11 7 8 5 4 1 9 6 9 10...

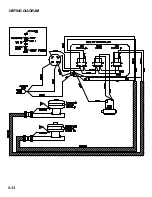

Page 30: ...WIRING DIAGRAM 5 13...

Page 31: ...NOTES 5 14 NOTES...