CR2 Manual 29/03/21

Page 19 of 29

CLEANING UPHOLSTERY

CAUTION – WE STRONGLY RECOMMEND ATTENDING AN UPHOLSTERY CLEANING COURSE BEFORE

ATTEMPTING TO CLEAN FABRIC UPHOLSTERY.

General instructions

Cleaning upholstery with success requires a good knowledge of the type of fabric to be worked on. Look for the

cleaning instruction label sewn on the underside of the furniture for the recommended method of cleaning the

fabric. If it calls for dry cleaning, do not attempt to clean with the wet extraction method. Otherwise, damage to

the fabric could occur. Extraction works perfectly on most wet-cleanable fabrics including synthetic (acrylic)

velvets.

Before proceeding, test the fabric for colour-fastness. Apply a small amount of ready-to-use cleaning solution on

the fabric in an inconspicuous area. Wait for 2 to 3 minutes and blot the area with a white terry cloth towel. If no

colour comes off onto the towel, the fabric should be safe to clean. If a little colour comes off, there is some risk

of colours running when you clean. It may be possible to stabilise colours by cleaning with B109 Fibre & Fabric

Rinse.

Prepare the machine in the same manner as for carpet (see preparing the machine) cleaning except attach the

upholstery tool to the vacuum hose. Connect the solution hose. Pour warm water into the solution tank. Turn on

the vacuum and pump switches.

Clean with the upholstery tool using as little solution as possible by decreasing the pump pressure with regulator

valve. Make overlapping passes to prevent streaking. Go over the area you just cleaned without depressing the

lever (vacuum only) and gauge the amount of moisture extracted for dryness. On heavily soiled areas like arm

rests, pre-treat with a recommended pre-spray.

STORAGE AND TRANSPORTATION

The machine can be prepared for storage (indoors only), by ensuring the power cord is coiled and secured using

the cord storage provided.

The solution tank and waste tank are empty and clean.

The drain hose cap is fitted to the waste tank.

Transporting the machine to another site in a vehicle can be carried out if the previous conditions are met but the

machine must be securely stowed.

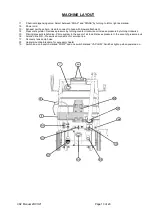

If the machine is to be lifted into a vehicle two lifting points are supplied one being the handle recess on the front

of the machine and the other the handle recess on the back of the machine.

Due to the weight of the machine it may require two people to lift it into any vehicle, or carry it upstairs.

Caution,

under no circumstances should the machine be bumped up a flight of stairs using the handle, always

empty the tanks before storage or transporting the machine.

USE OF PERSONAL PROTECTIVE EQUIPMENT (PPE)

Operation of this machine requires the use of protective latex gloves. Please be aware that the chemicals may

require specific PPE to be worn. This can be found on the Material Safety Data Sheet (MSDS) for that particular

product.