www.usaprocom.com

200204-01B

10

INSTALLATION

Gas Inlet / Gas esté

INLET GAS PRESSURE MAX 1/2 PSIG (3.5 KPa)

200110-01B

03/15

WARNING:

Make sure Regulator Cap is in the appropriate position

as shown in diagrams. Installation and service should be done by

qualified service technician only.

Natural Gas

When using natural gas:

Make sure the cap is installed in the propane/LP inlet of regulator.

Use thread sealant to assure there are no leaks.

Propane/LP Gas

When using propane/LP gas:

Make sure the cap is installed in the natural gas (NG) inlet of regulator.

Use thread sealant to assure there are no leaks.

ADVERTENCIA:

Asegúrese la tapa del regulador esté en la posición adecuada,

como se muestra en los diagramas. La instalación y reparaciones deben ser realizadas

por un técnico de servicio calificado solamente.

Gas Natural

Cuando se utiliza gas natural:

Asegúrese de que la tapa está instalado en el propano/LP entrada del regulador.

Utilice sellador de roscas para asegurar que no haya fugas.

Propano/LP Gas

Cuando se utiliza el gas propano / LP:

Asegúrese de que la tapa está instalado en la entrada de gas natural (GN) del regulador.

Utilice sellador de roscas para asegurar que no haya fugas.

Correct Pilot Flame Pattern

Incorrect Pilot Flame Pattern

NG

3-3.5" WC

Natural Gas

Shown

LP

8-11" WC

NG

3-3.5" WC

Natural Gas

Shown

LP

8-11" WC

1/2 Glass

Height

1/2 Glass

Height

Yellow

Tipping

Correct Burner Flame Pattern

Incorrect Burner Flame Pattern

LP

Blue Plunger

INSTALL SUPPLIED CAP IN FITTING

NOT BEING USED.

INSTALAR TAPA SUMINISTRADA MONTAJE NO SE UTILIZA.

NG

Yellow Plunger

This appliance may be installed in an aftermarket,*

permanently located, manufactured (mobile) home, where

not prohibited by local codes.

This appliance is only for use with propane or natural gas.

Field conversion by any other means including the use of

a kit is not permitted.

WARNING: Make sure the supplied cap is

installed in unused regulator fitting before

connecting the correct gas supply line.

WARNING: Do not use natural gas and

propane gas together.

CAUTION: Two gas line installations at

the same time are prohibited.

ADVERTENCIA: Asegúrese de que la línea

no utilizado se conecta por primera vez

antes de conectar la línea de suministro

de gas correcta.

ADVERTENCIA: No utilice el gas natural y

el gas propano juntos.

PRECAUCIÓN: Dos instalaciones de

líneas de gas al mismo tiempo están

prohibidos.

FOR PROPANE GAS SUPPLY

PARA LA FUENTE DE GAS DEL PROPANE

CAUTION: The heater requires an external regulator to reduce

the LP tank pressure to a maximum of 14" W.C. Never connect

this product directly to the supply tank.

PRECAUCIÓN: El calentador requieres una externa regulador

para reducir la presión del tanque de gas a un máximo de 14"

W.C. Nunca conecte este producto directamente al tanque de

suministro.

FOR NATURAL GAS SUPPLY

PARA LA FUENTE DE GAS DEL NATURAL

NOTICE: An additional gas regulator will be necessary if the

local natural gas pressure exceeds the heater's rated maximum

inlet pressure. If in doubt, contact the local gas utility. If natural

gas inlet pressure exceeds 10" W.C., the safety pressure switch

will activate. See owners manual for proper procedure to bypass

the pressure switch.

AVISO: Un regulador de gas adicional será necesario si la

presión del gas natural local excede de entrada nominal máxima

del calentador presión. En caso de duda, póngase en contacto

con la compañía de gas local. Si la presión de entrada de gas

natural supera los 10" WC, el interruptor de presión de

seguridad se activará. Consulte el manual del propietario para el

procedimiento adecuado de derivación el interruptor de presión.

Procom Heating, Inc. U.S. Patent Information

This product may be covered by one or more of the following

United States patents:

8,915,239 8,851,065 8,764,436 8,757,202 8,757,139 8,752,541

8,568,136 8,545,216 8,517,718 8,516,878 8,506,290 8,465,277

8,317,511 8,297,968 8,281,781 8,241,034 8,235,708 8,152,515

8,011,920 7,967,006 7,967,007 7,654,820 7,730,765 7,677,236

7,607,426 7,434,447

Other patents pending.

TOLL-FREE Customer Care Number: 1-866-573-0674

Numero de Atención al Cliente GRATUITO: 1-866-573-0674

Visit our website for more information www.usaprocom.com

Visite nuestra página web para más informacion www.usaprocom.com

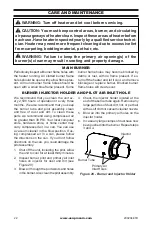

Figure 7 - Back of Stove

Gas Connection

Yellow Natural Gas

Plunger Underneath

Metal Cap

Blue Propane/LP Gas

Plunger Underneath

Dust Cover

Figure 8 - Gas Regulator

Insert Gas Fitting

for Natural Gas

Insert Gas Fitting

for Propane/LP Gas

Blue Dust Cover

DO NOT REMOVE

Blue Propane/LP

Plunger

Install Gas Fitting Here

GAS SELECTION

This appliance is factory

preset for propane/LP gas.

No changes are required for

connecting to propane/LP.

Only a qualified installer or service

technician can perform gas selec-

tion and connecting to gas supply.

CAUTION: Two gas line in-

stallations at the same time are

prohibited.

CAUTION: To avoid gas leak-

age for the gas not being used at

the inlet of regulator, a qualified

installer or service technician

must use supplied cap.

You will notice a color coded

plunger on the inside of the regu-

lator. This is normal. When the in-

let connection fitting is inserted

and tightened, this plunger will

be pushed back by the fitting

making all of the adjustments

for the gas being supplied. DO

NOT REMOVE THE PLUNGER.

The regulator will not work.

The inlet regulator is color coded

for identification of the correct

gas type. Blue is for propane (LP

gas) and yellow is for natural gas.

FOR PROPANE/LP GAS

INSTALLATION: BLUE

1. Remove blue dust cover.