PRO-COM OWNER’S MANUAL

VENTED GAS LOGS 5 WAL21-01

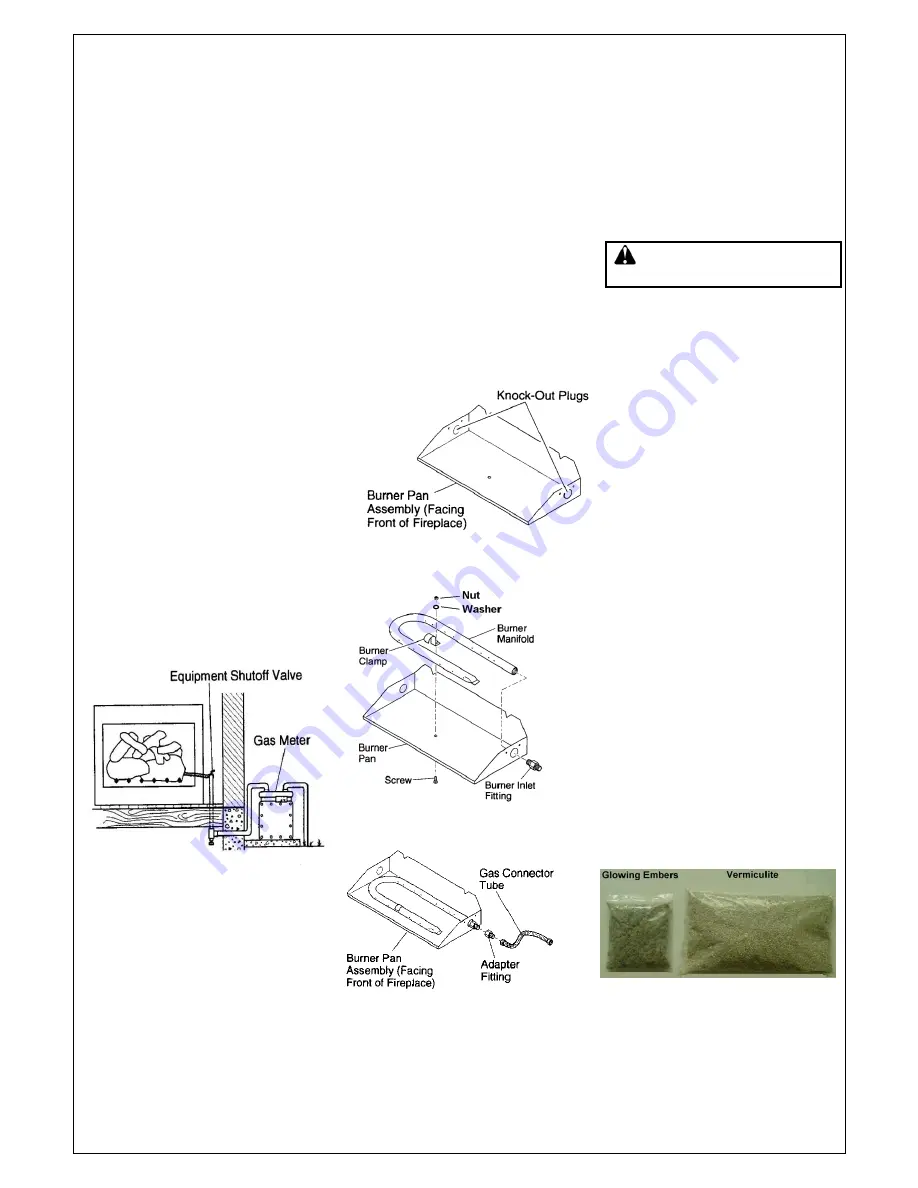

Figure 8- Connecting Gas to Appliance

Figure 9- Glowing Embers and

Vermiculite

Figure 5 –Checking Gas Joints

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see

Figure 5).

2. Pressurize supply piping system by

either using compressed air or opening

main gas valve located on or near gas

meter.

3. Check all joints from gas meter to

equipment shutoff valve (see Figure

5). Apply mixture of liquid soap and

water to gas joints. Bubbles forming

show a leak.

4.

Correct all leaks immediately.

ADDING PAN MATERIAL

1. Open the bag of ash bed material

(vermiculite) and spread it evenly

across the burner pan to the top. You

may over-flow the front and sides of the

pan to cover the entire pan and

connecting hardware. Do not cover

control system valve.

2. Open the glowing embers and evenly

cover the ash bed material (vermiculite)

in the burner pan.

Pressure Testing Gas Supply

Piping System

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1. Disconnect appliance with its appliance

main gas valve (control valve) and

equipment shutoff valve from gas supply

piping system. Pressures in excess of

1/2psig will damage heater regulator.

2. Cap off open end of gas pipe where

equipment shutoff valve was connected.

3. Pressurize supply piping system by either

using compressed air or opening main

gas valve located on or near gas meter.

4. Check all joints of gas supply piping

system. Apply mixture of liquid soap and

water to gas joints. Bubbles forming show

a leak.

5. Correct all leaks immediately.

6.Reconnect log set and equipment shutoff

valve to gas supply. Check reconnected

fittings for leaks.

TESTING BURNER FOR LEAKS

1. Generously apply soapy solution to

all connections.

2. Light the burner with the shutoff

valve, no more than half open, and

holding a match slightly in front of the

pan (see Lighting Instructions, page 6).

3. Inspect all connections for bubbles,

raw gas odor, or flame from any area

other than the burner (leaks). If leaks

are detected, shut off the gas valve

immediately. Tighten, or reassemble

the loose connection(s) using pipe joint

compound until burner system is leak

free.

4. When the burner is tested and leak

free, observe the individual tongues of

flame on the burner.

Note

: The burner

design includes more ports on the

outside of the bar. Make sure that all

ports are clear and producing flame

evenly across the burner. If any ports

appear blocked, clear them by

removing the burner manifold and

reaming the ports with a modified

paper clip or other suitable tool.

5. When finished testing, turn the gas

shutoff valve OFF to extinguish all

flames.

INSTALLATION

Continued

Installation and Gas Connection

1. Place the burner pan assembly in

the center of the fireplace floor. Make

sure the front of pan faces forward.

2. Thread the gas supply fitting to the

fireplace gas supply pipe. Use thread

sealant.

3. Install adapter fitting onto the burner

inlet fitting using thread sealant on

male threads of burner inlet fitting

(see Figure 8).

4. Install the gas connector tube to the

gas supply fitting. Carefully shape

tube to attach to adapter fitting.

WARNING:

Never check

for gas leaks with open flame.

INSTALLING THE GRATE, LOGS

See Page 10-15 Logs installation

HEARTH KIT ASSEMBLY

AND INSTALLATION

Kit Assembly

Note:

The following instructions

apply to dual flame "U" style

burners. Be sure all pipe threaded

connections are tight, and have

thread compound to prevent leaks.

1. Determine which side the gas line

will be coming into the fireplace.

2. Using a hammer and screw driver,

remove knock-out plug from the side

of the pan that corresponds to the

gas line (see Figure 6).

3. Unscrew burner inlet fitting from

burner manifold (see Figure 7).

4. Place burner manifold in pan with

threaded opening facing open

knock-out plug.

5. Using thread sealant (resistant to the

action of natural gas) on larger end of

fitting, screw the burner inlet fitting

through hole and into burner manifold.

Tighten using a wrench.

6. Using burner clamp, screw, and nut

provided, assemble clamp to pan.

This will hold the burner manifold in

place.

7. If using optional control system kit,

follow instructions included with kit for

installation and operation.

Figure 6 – Knock-Out Plug Locations

Figure 7 – Installing Burner