Prodigy

r

Manual Powder Spray Gun

8

Part 1053680E05

E

2007 Nordson Corporation

Nozzle Disassembly and Cleaning

Requirements: Nozzle Tool 1073682

1. Hold the nozzle firmly in one hand. Thread the

tool onto the threaded end of the insert until it

bottoms out on the electrode ring.

Insert

Electrode Ring

Tool

Figure 4

Nozzle Disassembly Step 1 (Shown with Nut

Installed)

2. Turn the tool clockwise while pulling on it until

the electrode ring/insert assembly comes out of

the nozzle.

NOTE: If the electrode is pulled out of the nozzle

shell, be careful to not lose it. The dual slot nozzle

has the electrode glued in.

Figure 5

Nozzle Disassembly Step 2A

Electrode Ring/Insert Assembly

Figure 6

Nozzle Disassembly Step 2B (New Style

Assembly Shown)

3. Unscrew the tool from the electrode ring/insert

assembly and blow off the assembly with

compressed air.

Figure 7

Nozzle Disassembly Step 3 (New Style

Shown)

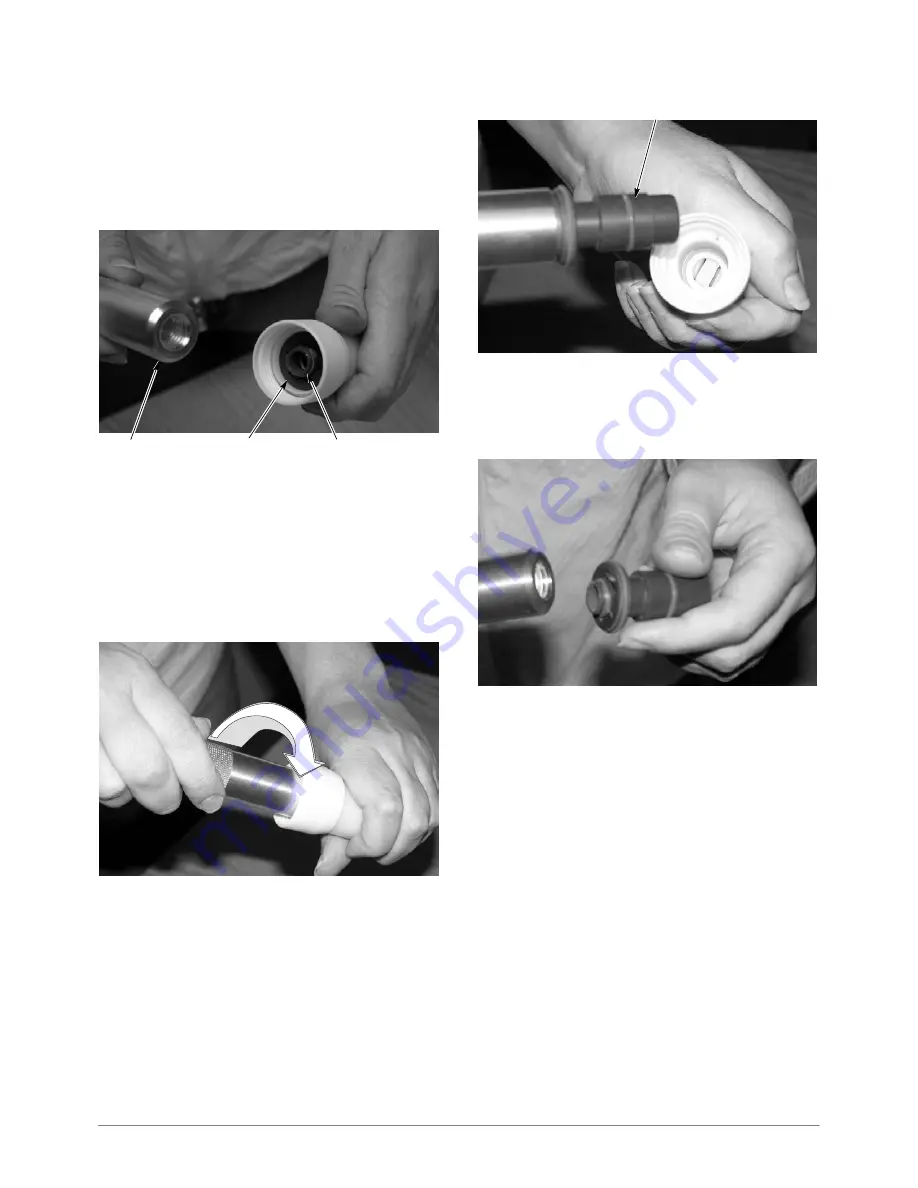

4. Place the nozzle and nozzle nut in an ultrasonic

cleaner to remove any impact fusion, then blow

them off with compressed air. If desired,

remove the nozzle nut from the nozzle by

sliding the nut forward then turning it clockwise

to unscrew it.

NOTE: See Figure 9. Old style nozzles have a

disk-shaped filter (3) installed on the outside of the

insert (6) and held on by the electrode ring (2).

New style nozzles have a conical filter that is

installed inside the front end of the insert. The old

style filter and insert are obsolete. if you are

replacing the filter on an old style nozzle, you must

also order a new insert. The new filters are

available in quantities of 10.