PM 11 90

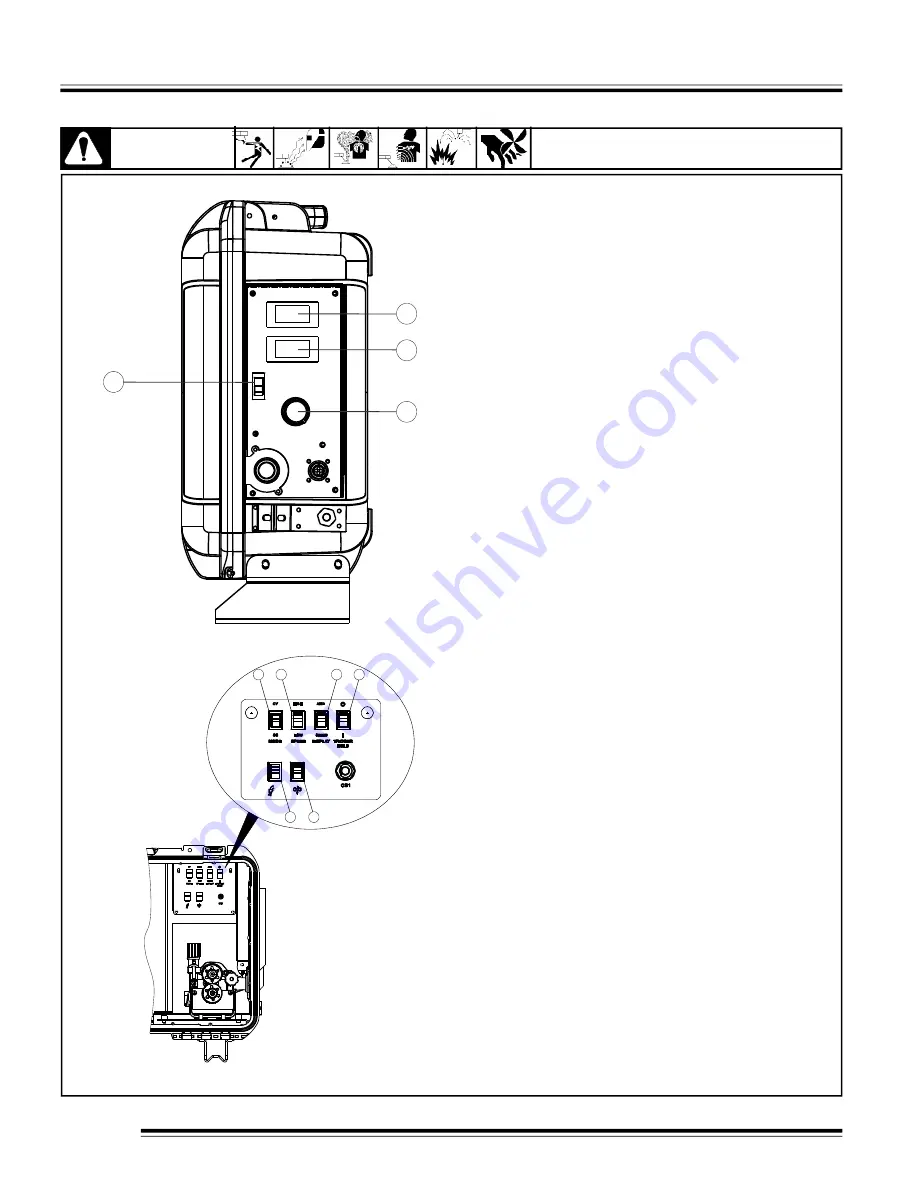

FIGURE 4-1 Controls With Meters

1 Power Control Switch

2 Wire Speed / Amperage Meter

Displays preset wire speed. While welding in CC mode,

actual wire speed is dependant on arc voltage.

Amperage displayed at the feeder is approximate.

Refer to power source for actual amperage.

3 Voltmeter

Displays actual arc voltage or open circuit voltage at the

feeder.

4 Wire Speed Control

Use control to adjust wire speed within the speed range

selected by the wire speed range switch, located on the

inner control panel. Maximum wire speed may be limited by

arc voltage.

5 CC/CV Switch

Use switch to match feeder with the output of the power

source.

While welding in CC mode, actual wire speed is dependent

on arc voltage.

While welding in CV mode, the wire feeder remains at

constant speed and the wire speed is not dependent on arc

voltage. Maximum wire speed may be limited by arc voltage.

6 HI/LO Speed Range Switch

Use switch to select speed range. High range is 100 to 800

Inches per Minute (2.5 to 20.3 Meters per Minute). Low range

is 25 to 200 Inches per Minute (0.6 to 5.1 Meters per Minute).

7 Display speed / inches per minute

Wire Speed / Amperage Meter will display only W ire Speed

in Inches per Minute.

Display amperage

Wire Speed / Amperage Meter will display Amps while

welding.

8 Trigger Hold Switch

Trigger hold allows operator to weld without holding gun

trigger.

To use trigger hold function, place trigger hold switch in the

I

position.

Press and hold the trigger. W elding will continue when

trigger is released.

To stop welding, press and release the trigger.

9 Jog Switch

Pressing the Jog switch allows the operator to jog wire

without energizing the contactor or gas valve.

10 Purge Switch

Pressing the Purge switch allows the operator to

purge gas lines before welding and to preset gas

flow rate at the flowmeter.

4.1 Controls With Meters

SECTION 4 OPERATION

8

1

2

3

4

9

10

5

6

7

8

CAUTION

SEE SAFETY BLOCKS at beginning of manual

bef ore proceeding.

Summary of Contents for PRO-1VS

Page 3: ...PM1190...

Page 7: ...PM1190...

Page 23: ...NOTES...

Page 25: ...NOTES...

Page 26: ...NOTES...

Page 27: ...Distributedby PROFAX 1603 North Main Street Pear Land Tx 77581 Phone 281 997 2671...

Page 28: ......