©2020 Hot Melt Technologies, Inc

Page 7

Proflex

®

G9-4

Temperature and System Controls

Operating Instructions

8

9

Zone Temp and Status Display buttons:

Press and hold any

zone button, (e.g. Tank, Hose, Gun, Grid) to display the set

temperature, then release to see the actual temperature.

The selected zone’s status (Sensor Fault, Ready, etc.) will also

be displayed in the Zone Status area.

Hose/Gun On/Off buttons:

Turns the power ON or OFF to each

hose/gun group individually. The LED illuminates accordingly.

Front Panel Lock:

Used to secure the front panel. To enhance

the systems tamper resistance, a key lock option is available.

Auto Standby Timer

*

:

To change, place Set/Run switch in set position. Push the

Auto Standby button and use the “+” and “–” arrows to

adjust from 0 to 5 hours. Return the Set/Run to run position.

Power OFF Timer

:

To change, place Set/Run switch in set position. Push the

Power Off button and use the “+” and “–” arrows to adjust

from 0 to 5 hours. Return the Set/Run to run position.

Manual Standby

*

:

If activated, LED will light and all

temperatures will lower to set % value.

To change % of standby, place Set/Run switch in set

position. Push the Temperature Set Back Control button

and use the “+” and “–” arrows to adjust from 20% to 70%.

Return the Set/Run switch to run position. The programmed

% applies to both Auto and Manual Standby.

Pump Ready Delay Timer

*

:

If additional melted adhesive is

needed, this feature adds up to 60 minutes of time before

allowing the pump motor to work.

To change, place Set/Run switch in set position. Push the

Pump Ready delay button and use the “+” and “–” arrows

to adjust from 0 to 60 minutes. Return the Set/Run switch

to run position.

Pump Ready:

The pump motor will not operate until

the actual tank temperature is within 25°F (14°C)

of set temperature.

Pump ON/OFF Switch:

The pump will only operate when: this

switch is ON, the “READY” LED is lit (see #14 above), and a

trigger input is provided.

Set/Run switch

*

:

Should be in Run Mode during normal

operation. Place in Set Mode to change set temperatures

of any zone, (e.g. Tank, Hose, Gun, Grid) or values of other

features (e.g. High Limit, Auto Standby Timer, etc.). Return

switch to Run Mode when finished with adjustment(s).

All Zone Ready:

To restrict operation of the pump until

all active zones, (e.g., Tank, Hose and Gun) have reached

their respective Ready Temp, set the All Zone Ready dip

switch to ON.

°F vs °C:

Dip switch used to change from °F or °C

(default is Fahrenheit) For Celsius set the switch to ON.

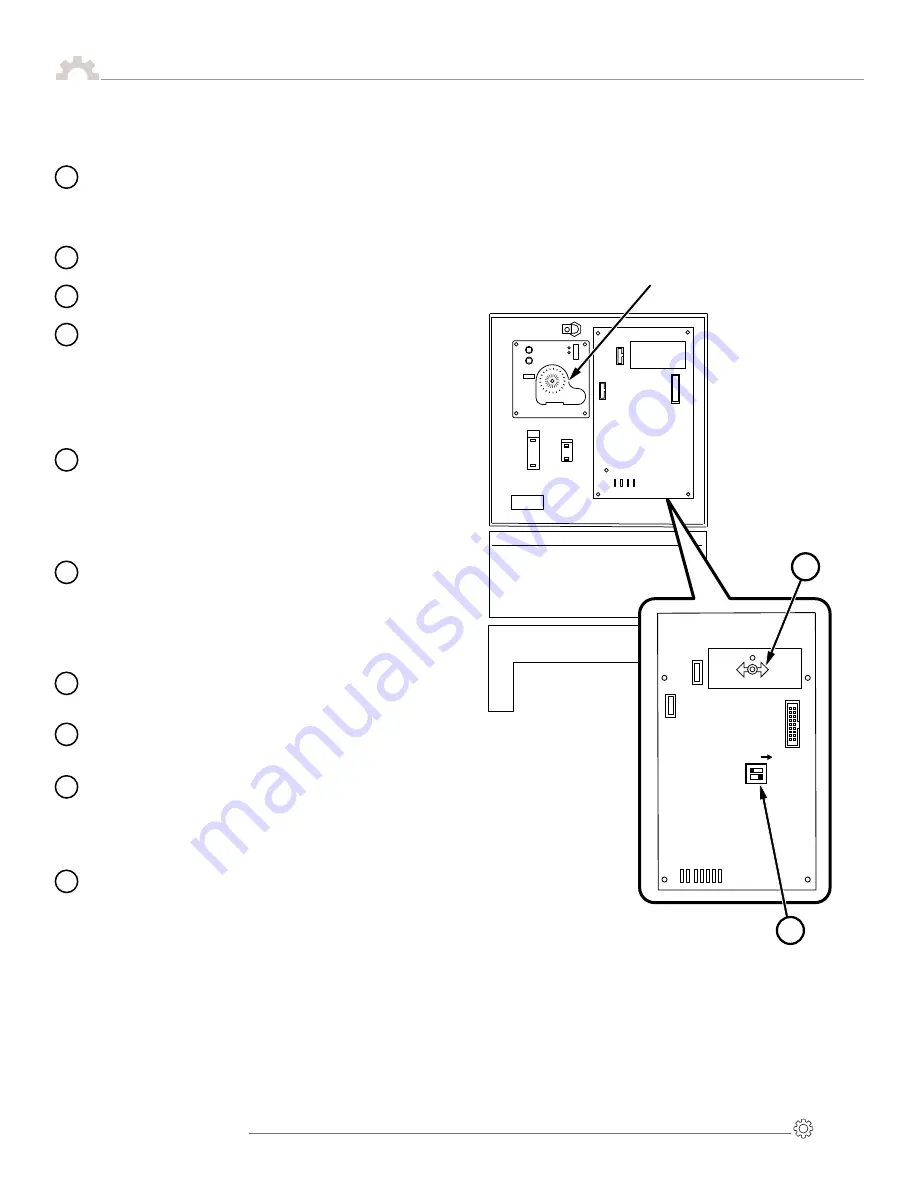

10

11

12

13

14

15

17

16

Set Mode Run Mode

ALL ZONE READY

CELSIUS

ON

16

17

Optional 24-7 Timer

(934-247)

*System will return to normal operation if no adjustments are made for 15 seconds.

Set Mode LED on front panel will flash, indicating switch is still in Set Mode position.

07/08/20 Rev A