4-

MAINTENANCE

RECOMMENDATIONS

A periodic visual check of the following is recommended:

-

Cleanliness of the coil

-

Fan operation

-

Position of axial fans in their collar

-

State of each axial fan (tightness to shaft, mechanical state of blades etc)

If the unit is stopped for long periods of time, the fan motors should be run for at least two hours each week.

4.1

CLEANING - GENERAL RULES

It is strongly recommended to regularly clean coil of the heat exchanger, at least once a year. Insufficiently maintained equipment will have a

short life expectancy, compared with an identical equipment with regular routine maintenance.

An insufficiently maintained equipment exposed to an aggressive environment, may be quickly deteriorated, even if an appropriate protective

treatment has been applied for the manufacturing of equipment.

The purpose of the cleaning is to get rid of all the hydroscopic crystals as well as deposits of all kinds.

Depending on the environmental and operating conditions, it may be necessary to increase the frequency of cleaning, particularly depending on:

- operating time of the fans

- quality of the surrounding air (proximity to sea, factories, relative humidity, ...)

- presence of adiabatic ramps

The frequency of the cleaning operations is mainly function of the conditions of use and of the amount of the deposits. That's why, it is

recommended to regularly carry out a visual inspection of the exchanger in order to start a cleaning operation as soon as necessary.

A late cleaning :

- will take longer time to achieve

- will be more complex to achieve

- reduces the life expectancy of the exchanger

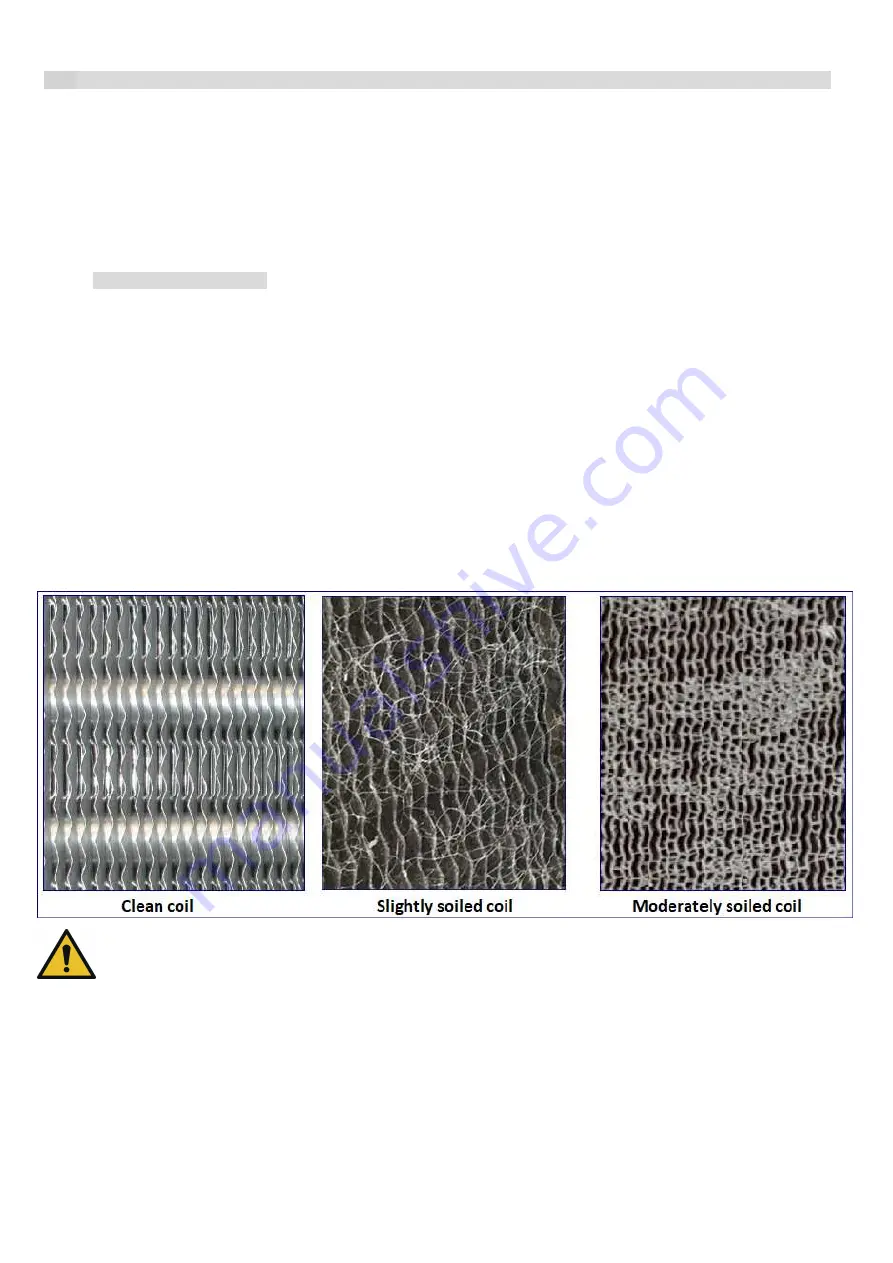

Below, 3 pictures of exchangers at different states of soiling (photos given as an indication).

Turn off the entire unit, and secure the unit against unintentional power-on.

Comply with the site's specific safety instructions.

For heat exchangers with BLYGOLD® or HERESITE® coating, refer to the paragraph specific to each treatment.

If the fins are damaged, it is necessary to straighten them with an appropriate tool before starting a cleaning procedure.

Adiabatic system

Misuse of adiabatic systems can become an aggravating factor in heat exchanger soiling. As a reminder:

- Only PROFROID adiabatic supplied systems must be used on PROFROID exchangers. Any other system of misting, spraying or watering is

prohibited

- The quality of the water must be regularly checked according to the criteria described in our Instruction and Operation Manual (IOM), see

chapter 5. This verification must be recorded in the maintenance book of the installation.

- Direct spraying of the water on the heat exchanger is forbidden, refer to the rules for mounting the adiabatic systems, see chapter 5.

Summary of Contents for ADAGIO 50

Page 17: ...20 3 5 ...

Page 29: ......