TD92

Operator’s Manual

41

HYDRAULICS

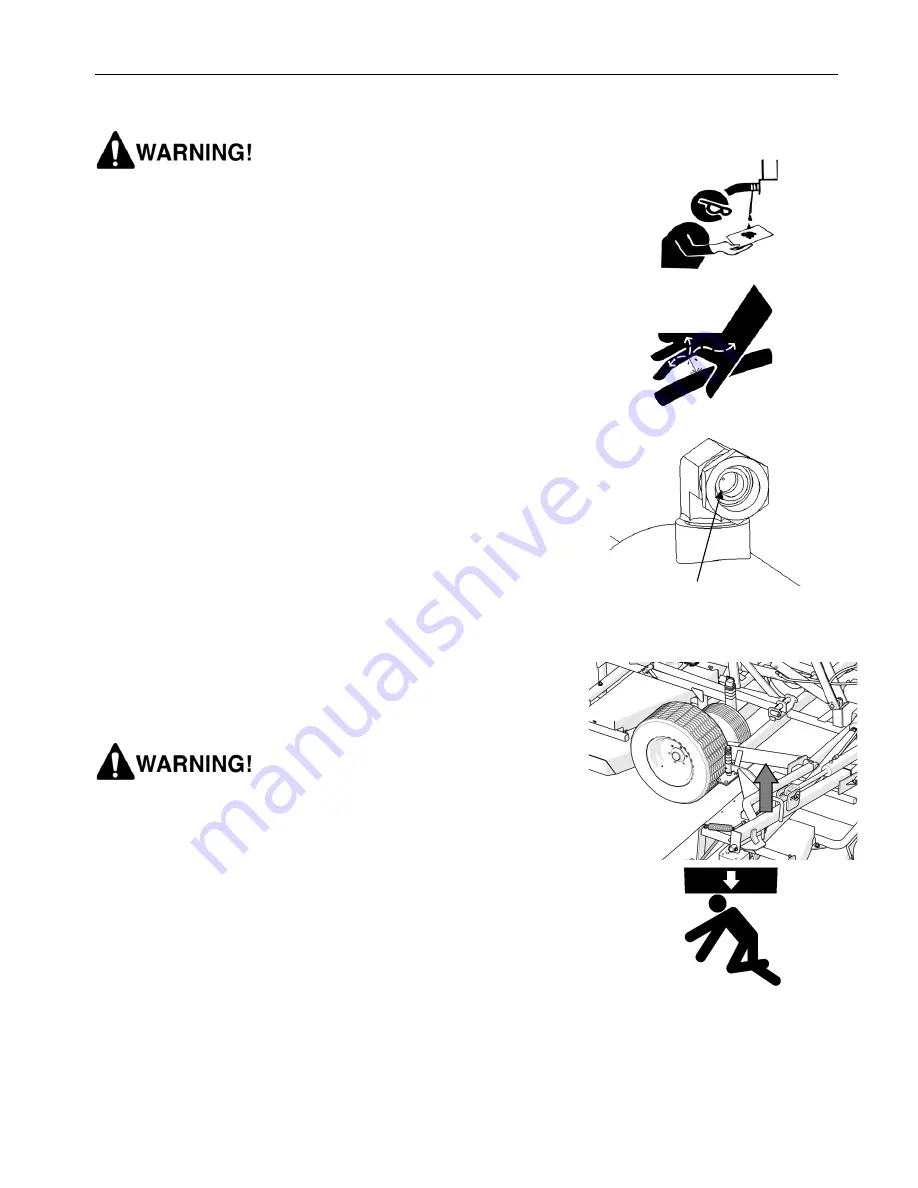

Do not use your hand to check for hydraulic oil leaks. Use a

piece of cardboard instead.

Hydraulic fluid escaping under pressure can penetrate the skin

causing serious injury. If skin penetration occurs, seek

medical attention immediately.

Relieve

all

pressure

from

hydraulic

system

before

disconnecting hoses.

During your daily inspection repair all leaks before they create a

major problem. Relieve all pressure before working on, or

disconnecting the line in the hydraulic system.

The hydraulic system on the TD92 mower is a simple cylinder

system used to raise and lower the cutting decks into position.

Each cylinder is equipped with a .032 diameter restrictor orifice in

the rod-end elbow adapter to throttle the speed of travel.

When reconnecting to the tractor, be sure that both connector ends

are clean. Dirt in the hydraulic system can block the orifice in the

line throttle valve or cause premature wear & failure of hydraulic

components on the mower or tractor.

SUPPORTING MACHINE FOR SERVICE

(2) Points are available to lift the mower off of the ground for

servicing the transport tires / wheels / bearings at the main frame

rail between the transport tire and deck corner pin support plate (as

shown in the accompanying illustration.) Use a bottle or service

jack to raise the wheel from the ground and place a wooden block

or other suitable support under the rectangular tube.

Do not support the machine on cinder blocks, hollow tiles or

other members that may fail under continuous load.

Never perform service on a machine that is supported solely

by a jack. Always ensure proper blocking is placed to support

load during service.

Transport tires must be changed with the wings in the raised

position. Ensure the machine is on a flat, level surface and the

wing locks are fully engaged before attempting to lift the

machine.

RESTRICTOR

Summary of Contents for TD 92

Page 2: ......

Page 48: ......

Page 52: ...TD92G Parts Manual ...

Page 54: ...TD92G Parts Manual 2 1 DECK ASSEMBLY 1 1 Blade Spindle Assembly 8 2020 ...

Page 55: ...TD92G Parts Manual 3 1 2 Blade Options ...

Page 56: ...TD92G Parts Manual 4 1 3 Gearbox Assembly ...

Page 57: ...TD92G Parts Manual 5 1 4 Wing Deck Assembly 8 8 2017 ...

Page 58: ...TD92G Parts Manual 6 1 5 Rear Deck Assembly ...

Page 59: ...TD92G Parts Manual 7 2 FRAME ASSEMBLY 2 1 Frame Assembly ...

Page 60: ...TD92G Parts Manual 8 2 2 Wing Lift Assembly ...

Page 61: ...TD92G Parts Manual 9 2 3 Tire Assemblies ...

Page 62: ...TD92G Parts Manual 10 2 4 Spare Tire Carrier Optional ...

Page 63: ...TD92G Parts Manual 11 3 HYDRAULICS 3 1 Hydraulics ...

Page 64: ...TD92G Parts Manual 12 3 2 Hydraulic Stabilizer Valves Optional ...

Page 65: ...TD92G Parts Manual 13 4 DRIVELINE 4 1 Driveline 9 2016 ...

Page 66: ...TD92G Parts Manual 14 4 2 Input PTO Shaft ...

Page 67: ...TD92G Parts Manual 15 4 3 Intermediate PTO Shaft ...

Page 68: ...TD92G Parts Manual 16 4 4 Deck PTO Shaft ...

Page 69: ...TD92G Parts Manual 17 4 5 Deck Gearbox ...