TDR-X Parts Manual

21

5 DECALS

5.1 Safety

If decals become faded, damaged, or lost, replace immediately. Order decal

according to corresponding part number below. Complete decal kits are also

available.

521784

DECAL

– HITCH SETUP

209115

DECAL

– OEM PARTS

209174

DECAL - CAUTION

209113

DECAL

– REPLACE SHIELDS

521817

DECAL

– PROGRESSIVE TURF

(B Models)

209175

DECAL

– GENERAL SAFETY

521817DE

DECAL

– PROGRESSIVE TURF

(D Models)

541503 - KIT - SAFETY DECALS FOR TDR-X

526001

DECAL

– PTO GREASE

209196

DECAL - BLADE HARDWARE

209173

DECAL - ROTATING BLADE DANGER

Summary of Contents for TDR-X

Page 2: ......

Page 48: ...TDR X Operator s Manual 46 ...

Page 54: ...TDR X Parts Manual 2 1 DECK ASSEMBLY 1 1 Blade Spindle Assembly ...

Page 55: ...TDR X Parts Manual 3 1 2 Deck Assembly ...

Page 56: ...TDR X Parts Manual 4 1 3 Deck Side Channel Assembly ...

Page 57: ...TDR X Parts Manual 5 1 4 Gearbox Assembly ...

Page 58: ...TDR X Parts Manual 6 2 FRAME ASSEMBLY 2 1 Frame Assembly ...

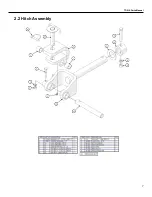

Page 59: ...TDR X Parts Manual 7 2 2 Hitch Assembly ...

Page 60: ...TDR X Parts Manual 8 2 3 Right Wing Assembly ...

Page 61: ...TDR X Parts Manual 9 2 4 Left Wing Assembly ...

Page 62: ...TDR X Parts Manual 10 2 5 Rear Lift Assembly ...

Page 63: ...TDR X Parts Manual 11 2 6 Lock Release Assembly ...

Page 64: ...TDR X Parts Manual 12 2 7 Wheel Assembly ...

Page 65: ...TDR X Parts Manual 13 3 HYDRAULICS ...

Page 66: ...TDR X Parts Manual 14 4 DRIVELINE 4 1 Driveline Layout ...

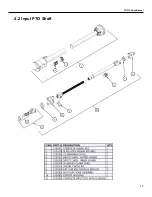

Page 67: ...TDR X Parts Manual 15 4 2 Input PTO Shaft ...

Page 68: ...TDR X Parts Manual 16 4 3 Intermediate PTO Shaft ...

Page 69: ...TDR X Parts Manual 17 4 4 Wing Deck PTO Shaft ...

Page 70: ...TDR X Parts Manual 18 4 5 Rear Deck PTO Shaft ...

Page 71: ...TDR X Parts Manual 19 4 6 4 Way Gearbox ...