37

TDC

ENSURE COUNTER-WEIGHT IS ALIGNED BOTTOM

DEAD CENTER (BDC) BEFORE INSTALLATION

BDC

17

44

46

45

16

18

31

30

17

1

2

3

4

TORQUE SEQUENCE

ENSURE CONNECTING

ROD IS CENTERED IN

DIAPHRAGM OPENING

TORQUE:

27 ± 3 IN-LBS

TORQUE: 27 ± 3 IN-LBS

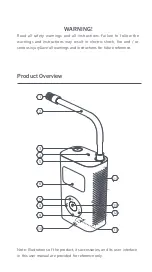

Figure I.

Figure H.

49

49

48

6

Black Motor Gear

with 38 Teeth.

NOTE: ORIENTATION

AS

PER TEXT ON GEAR

38 TEETH

SHAFT TO BE

FREE OF ALL

ADHESIVES/

LUBRICANTS

WOOD BLOCK

TO SUPPORT SHAFT

13 mm

DEEP

SOCKET

SOFT

HAMMER

Figure J.

10.

Position the connecting rod assembly (item 37) so that it is in

BDC (see figure H), and ensure the diaphragm (item 41) is

concentric to the “diaphragm opening”.

NOTE:

this operation is CRITICAL prior to proceeding onto step 11.

11.

Install the cylinder head assembly (item 46) and valve cover (item

18) and secure with four M5 screws (item 16) and lock washers

(item 17). Torque the screws according to the torque sequence

shown in figure I inset.

12.

Install the compressor cover (item 31) and secure with four screws

(item 30) and lock washers (item 17).

13.

Orient the Motor Gear (item 49) as noted in figure J. (Inset) with

appropriate side facing Motor flange as per gear text. Install by hand

and secure to the Motor Shaft with a new retaining ring (item 48).

If gear cannot be installed by hand, a 13 mm deep socket and soft

hammer can be used to lightly tap gear onto shaft. Support Motor

shaft from combustion air blower side as shown in figure J.

Copy Part# 206000, Rev. E

Page 6 of 9

Date: 05/2017

© 2010 Marine Canada Acquisition Inc. DBA SEASTAR SOLUTIONS 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6

Tel: 604.270.6899

Web: www.proheat.com

INSTALLATION INSTRUCTIONS