TORQUE SPECIFICATIONS

1.3

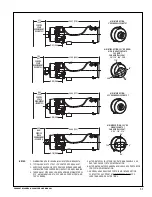

Solenoid Valve

•

Lubricate O-ring with diesel fuel.

•

Install solenoid valve by hand.

•

Ensure poppet and spring remain in place during assembly.

•

Torque solenoid valve to fuel block to 25 in. lbs. ± 3 in. lbs.

(2.8 Nm ± 0.3 Nm).

Nozzle

•

Lubricate O-ring on nozzle with diesel fuel.

•

Torque nozzle to fuel block to 150 in. lbs. ± 10 in. lbs.

(16.9 Nm ± 1.1 Nm).

Nozzle Assembly

•

Torque nozzle to nozzle stem to 30 in. lbs. ± 3 in. lbs. (3.4Nm ± .3 Nm).

Fuel Delivery Block

•

Ensure all three O-rings are in place.

•

Torque screws (3) to 75 in. lbs. ± 7 in. lbs. (8.5 Nm ± 0.8 Nm).

Regulator

•

Install 2 o-rings on back side of regulator.

•

Torque screws (2) to 75 in. lbs. ± 3 in. lbs. (8.5 Nm ± 0.3 Nm).

1-9

PROHEAT M-SERIES G-II PCM SERVICE MANUAL

Summary of Contents for M105 G-II PCM

Page 7: ...PROHEAT M SERIES G II PCM SERVICE MANUAL B 2 ...

Page 11: ...PROHEAT M SERIES G II PCM SERVICE MANUAL D 2 ...

Page 25: ...PROHEAT M SERIES G II PCM SERVICE MANUAL 1 12 ...

Page 35: ...2 10 PROHEAT M SERIES G II PCM SERVICE MANUAL ...

Page 77: ...PROHEAT M SERIES G II PCM SERVICE MANUAL 4 40 ...

Page 89: ...6 2 PROHEAT M SERIES G II PCM SERVICE MANUAL ...