BLOW THIS DIRECTION

WHEN USING

COMPRESSED AIR.

PROHEAT M-SERIES G-II PCM SERVICE MANUAL

5-3

6.

Check Fuel System

•

Check the fuel system for damage, cracks or hardening from aging

or leakage.

•

Make sure the clamps on the fuel lines are secure.

7.

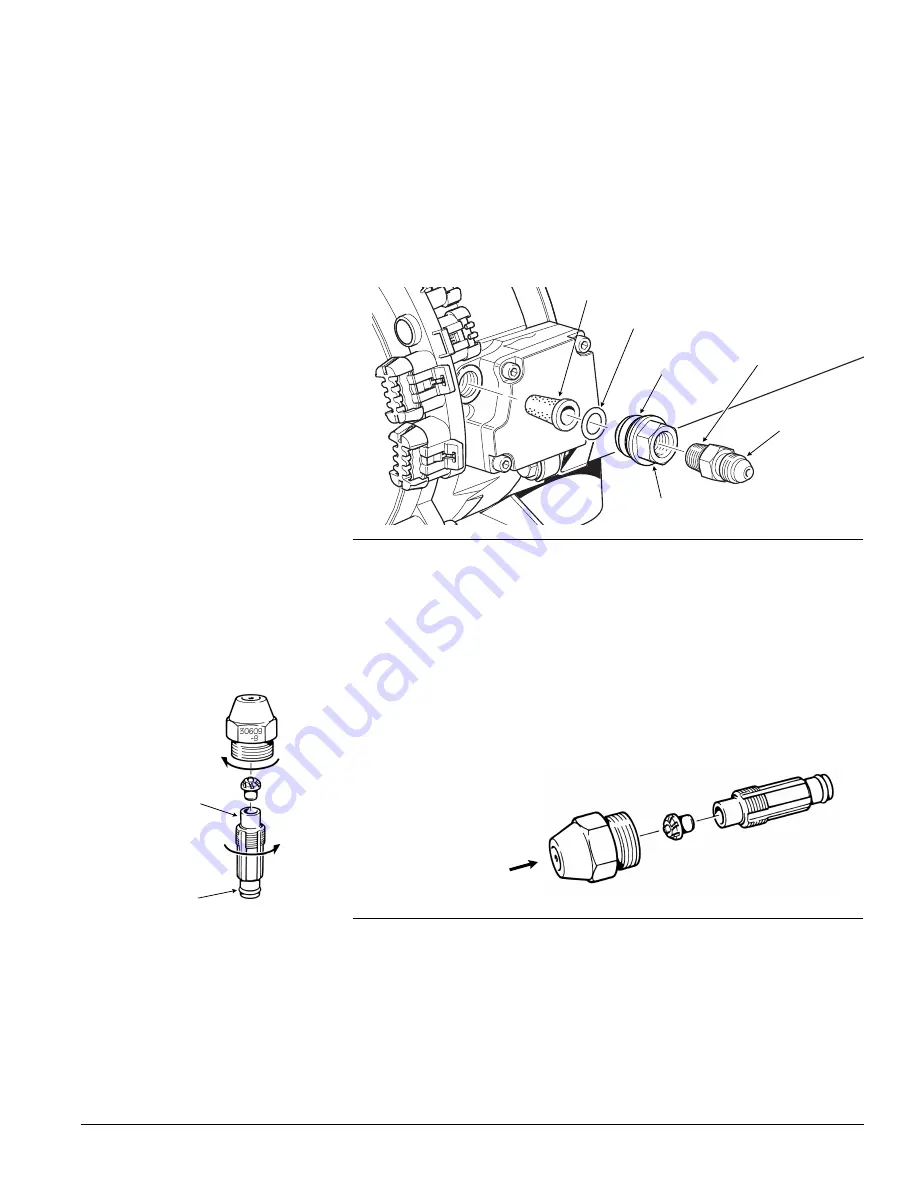

Check Fuel Filter

•

Remove and inspect filter. Clean or replace as necessary.

•

Clean O-ring and seat.

•

Refer to page 4-6, Step 2.

8.

Clean Nozzle

•

IInspect Fuel Nozzle stem and O-ring for contamination and/or damage.

Replace if damaged.

• Disassemble Nozzle, inspect and clean distributor (a soft bristled brush

may be used), fuel orifice, air passages, head and stem with electrical

contact cleaner or warm soapy water.

•

DO NOT use a welding torch tip cleaner

.

•

Refer to page 4-7.

FUEL FILTER

O-RING

O-RING

ADAPTER TORQUE =100 ± 10 IN. LBS

(11.3 ± 1.1 NM)

INLET FITTING

TORQUE = 100

± 10 IN. LBS

(11.3 ± 1.1 NM)

THREAD

SEALANT

REQUIRED

TORQUE = SEE

SECTION 1.3

LUBRICATE

O-RING WITH

DIESEL FUEL

HOLD UPRIGHT

TO ASSEMBLE

Figure 5-3: Fuel Filter.

Figure 5-4: Fuel Nozzle.

ARROWS

SHOW HOW TO

TIGHTEN THE

NOZZLE

Summary of Contents for M105 G-II PCM

Page 7: ...PROHEAT M SERIES G II PCM SERVICE MANUAL B 2 ...

Page 11: ...PROHEAT M SERIES G II PCM SERVICE MANUAL D 2 ...

Page 25: ...PROHEAT M SERIES G II PCM SERVICE MANUAL 1 12 ...

Page 35: ...2 10 PROHEAT M SERIES G II PCM SERVICE MANUAL ...

Page 77: ...PROHEAT M SERIES G II PCM SERVICE MANUAL 4 40 ...

Page 89: ...6 2 PROHEAT M SERIES G II PCM SERVICE MANUAL ...