PROLIGHTS - Astra

Wash7PixIP

34

Problems

Possible causes

Checks and remedies

Product doesn’t power

ON.

• No power to the

product.

• Check that power is switched ON and cables are

plugged in.

• Fuse blown or internal

fault.

• Check if the Fuse is intact and eventually replace it if

necessary.

•

Contact the PROLIGHTS Service or authorized service

partner. Do not remove parts and/or covers, or carry

out any repairs or service that are not described in

this Safety and User Manual unless you have both

authorization from PROLIGHTS and the service

documentation.

Product reset correctly but

does not respond correctly

to the contoller.

•

Bad signal connection.

• Inspect connections and cables. Fix eventual bad

connections. Repair or replace damaged cables.

• Signal connection not

terminated.

•

Insert DMX termination plug in signal output socket of

the last product on the signal line.

• Incorrect addressing of

the product.

• Check the product address and control settings.

• One of the product is

defective and is corrupt

-

ing the signal transmis

-

sion on the signal line.

•

Unplug the XLR in and out connectors and connect

them directly together to bypass one product at a

time until normal operation is regained. Once found

the error, have that fixture serviced by a qualified

technician.

Timeout error after fixture

reset.

• One or more hardware

components requires

mechanical adjustments.

• Check product stored error messages for more

information. Contact PROLIGHTS Service or an

authorized service partner.

Mechanical effect loses

position.

•

Mechanical

hardware

require cleaning, adjust

-

ment or lubrification.

• Check product stored error messages for more

information. Contact PROLIGHTS Service or an

authorized service partner.

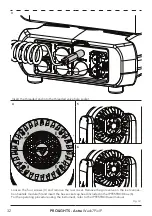

Light output turn OFF

Intermittently.

• Fixture is too hot.

• Check product stored error messages.

• Allow product to cool.

•

Clean the product and airflow filters.

• Reduce ambient temperature.

• Hardware failure (tem

-

perature sensor, fans,

Light source...).

• Check product stored error messages for more

information. Contact. PROLIGHTS Service or an

authorized service partner.

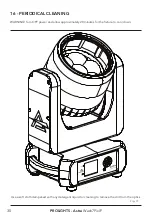

General low light intensity. • Dirty lens assembly.

•

Dirty or damaged filters.

•

Clean the fixture regularly.

• Install lens assembly properly.

Contact an authorized service center in case of technical problems or not reported in the table can not

be resolved by the procedure given in the table.

TROUBLESHOOTING