-4- DP2000-1725-7/04

Dough Pressing Operations

SETTING CRUST THICKNESS

CONTROL:

*The thickness is determined by dough

weight and temperature setting on each

platen. Setting crust thickness is as

simple as the twist of a dial. The

thickness adjustment dial can be located

on the top of the DP2000. By means of

trial and error, rotate the dial until

desired thickness is obtained. **If your

platens are polished they have been

coated with

Platen Saver

. This product

will prevent dough from sticking and

make cleanup much easier. A sample

bottle has been included along with an

order sheet for your convenience.

Note:

Never force the dial past its stop

position or damage could occur.

PRESSING DOUGH:

1.

First make sure you have the

correct type electrical current or

serious damage could occur!

2.

Press the Power Button in order

to turn the machine on. A green

light will illuminate above the

power button indicating that

power is in the machine.

3.

Both the upper and lower platens

will heat up once you have

adjusted your digital control to

your desired setting

. Note:

Different products require

different temperature settings. In

order to determine the right

temperature setting for your

product, refer to the following

table simply as a guide for

starting.

*To achieve consistent size flour

tortillas of smaller than 10” you will

need to only press 2 at a time as shown

in the pictures included with the

manual.

Note: Keep in mind that dough

formulations may differ, and that you

may have to do some trial and error

testing of different temperatures and

platen pressure to arrive at the proper

end result for your particular product.

Also note that the finished, after-

pressing diameter of the finished dough

piece is determined by the weight of the

dough and the amount of pressure

applied to the platens.

For best results, your dough should be

proofed at room temperature before

pressing, but it will also press directly

out of your refrigerator.

Flour is not

required to press a crust and should not

be dusted on any part of the machine.

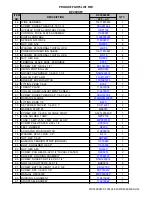

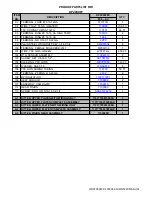

Press Only

Press & Par Bake

Dough

Product

Temp

Press

Time

Temp

Press

Time

Pizza

150°F

both

platens

3

seconds

325°F

both

platens

7-15

seconds

Flour

Tortilla

N/A

350°F

both

platens

1 quick

second

Corn

Tortilla

No heat,

must

use wax

paper

3

seconds

N/A

Mushi

Skin

150°F

both

platens

3

seconds

N/A

Summary of Contents for DP2000FPE

Page 16: ......