-3- DP1300

2/04

back of the press and air

compressor cabinet.

Note: The compressor portion of the

machine has a separate on/off switch

located on the rear of the lower cabinet.

2.

Switch the DP1300 to the ON

position.

Note: Initial temperature setting of

150°F has been shown to be acceptable

for most dough formulations; however,

you may have to determine the best

temperature for your own dough by trial

and error testing of your product at

different temperature settings.

3.

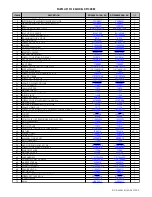

Set the timer in accordance with

the following information:

2-4 seconds

–For warm dough

with moderate yeast content.

2-6 seconds

– For room

temperature dough with

moderate yeast content.

6-8 seconds

– For cold dough

right out of the refrigerator with

low yeast content.

Remember that the timer does not

actuate until the upper platen mates

with the lower platen and resistance

is felt.

4.

Set the thickness control lever to

“thick” or “thin” or anywhere in

between these settings as your

product requires.

Note: Diameter and thickness is

determined through experimenting with

your own dough and is a product of

dough weight, temperature, pressing

time, and thickness setting.

5.

Swing open the lower platen and

apply a quick spray of a good

water based

food release on the

lower platen. Doughpro offers

its own food release spray

NATURALLY CLEAR Model

No. DPPC1. (See our catalog

and price list for information.)

Note: This spray

will not

affect

the taste of your crust in any

way.

6.

Place your pre-portioned ball of

dough in the approximate center

of the lower platen. Add another

dash of spray to the top of the

dough ball.

7.

Close the platen and, with both

hands, press the two green

buttons on each side of the

machine simultaneously.

8.

Hold the buttons in until

resistance is felt then release at

once. The timer will actuate and,

when the time cycle is

completed, the upper platen will

rise automatically (timer is preset

at factory for six (6) seconds, but

this is easily changed by

following the upcoming

instructions.)

9.

Remove the crust, place on a

disc, screen, pan or peel, add

toppings and bake.

ADDITIONAL NOTES:

Serial Tags

2/10