Use

Before use

Make sure the blade is not in contact with the part when the motor is started.

Run the motor and let the saw reach full speed. Start the cut by bringing the head down slowly over the part.

DO NOT LOWER THE HEAD BACK DOWN AND DO NOT FORCE IT. Allow the weight of the saw to make

the effort required for the cutting. The saw will automatically stop at the end of the cut.

Feed rate

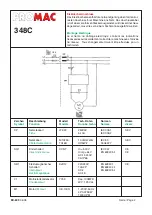

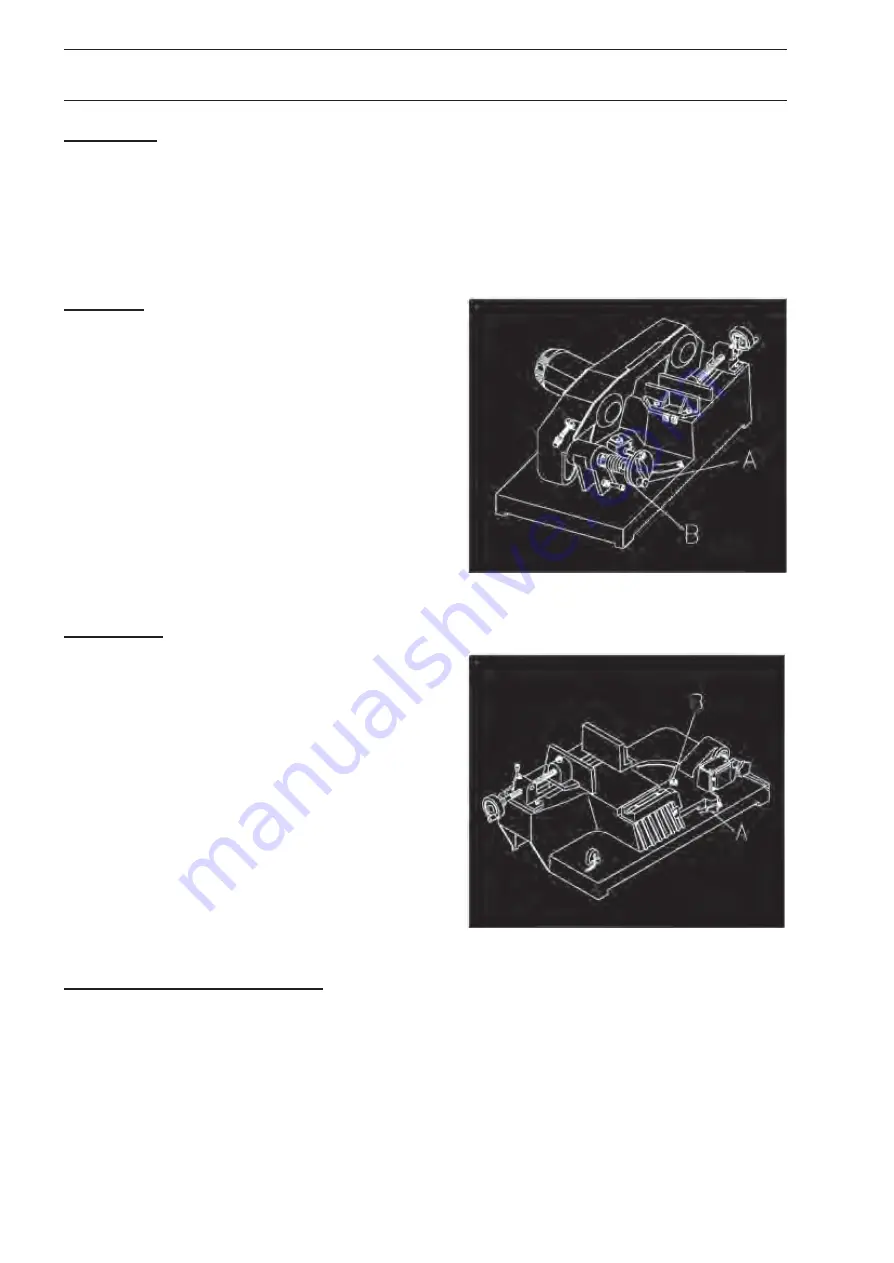

The feed rate is pre-set (mark H) in the factory for full

metal cutting.

To reduce the feed rate, proceed as follows:

1. Release the locking pin by gently pulling on button

(A) of Fig. 3.

2. Turn wheel (B) towards the button and stop at mark

M. Let the locking pin slide into the groove. The

feed rate is adjusted for cutting thicker metal tubing.

3. Turn the wheel, stop at mark L and lock it at this

position. The feed rate is adjusted for cutting thinner

metal tubing.

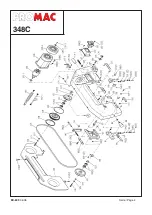

Oblique cut

The machine uses a pivoting mitre block for oblique cuts

from 0 to 45 degrees. The pivot arm has an an index -

(A) in Fig. 4. The machine is pre-set to zero degrees

when it leaves the factory. An oblique cut is adjusted in

the following way:

1. Loosen bolt (B) to release the arm.

2. Move the pivot arm forwards along the scale to find

the angle that best fits the part to be cut.

3. If the index corresponds to the appropriate

gradation of degrees on the the scale, tighten the

bolt. This will ensure cutting at the perfect angle.

Fig. 3

Fig. 4

Direction of travel of the blade

Make sure that the blade is mounted on the wheels in such a way that the vertical cutting edge engages first

with the part.

BEFORE STARTING THE SAW

DO NOT FORGET TO DETACH THE LOCKING TAB BETWEEN THE ARM OF THE SAW AND THE SAW

BENCH TO RELEASE THE SAW. AFTER USE DO NOT FORGET TO REPLACE IT TO PERMIT EASY

AND SAFE TRANSPORTATION OF THE MACHINE.

18

Summary of Contents for 348C

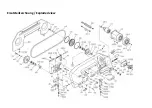

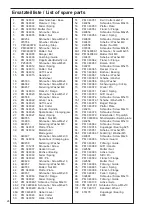

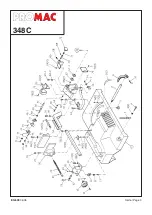

Page 22: ...Ersatzteilzeichnung Exploded view...

Page 23: ...Ersatzteilzeichnung Exploded view...

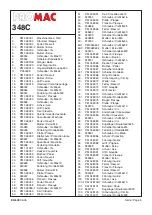

Page 29: ...Seite Page 3 EX 609 06 05 348C...

Page 30: ...Seite Page 4 EX 609 06 05 348C...