3

4.2 Noise emission

Acoustic pressure level (EN 11202):

Idling at maximum speed 73,4 dB (A)

The specified values are emission

levels and are not necessarily to be

seen as safe operating levels.

As workplace conditions vary, this

information is intended to allow the

user to make a better estimation of the

hazards and risks involved only.

4.3 Content of delivery

Four way tool post

Set of change gears

MT-5 fixed centre

MT-3 fixed centre

160mm 3-jaw universal chuck

Chuck guard

Splash guard

Assembly kit

Operating manual

Spare parts list.

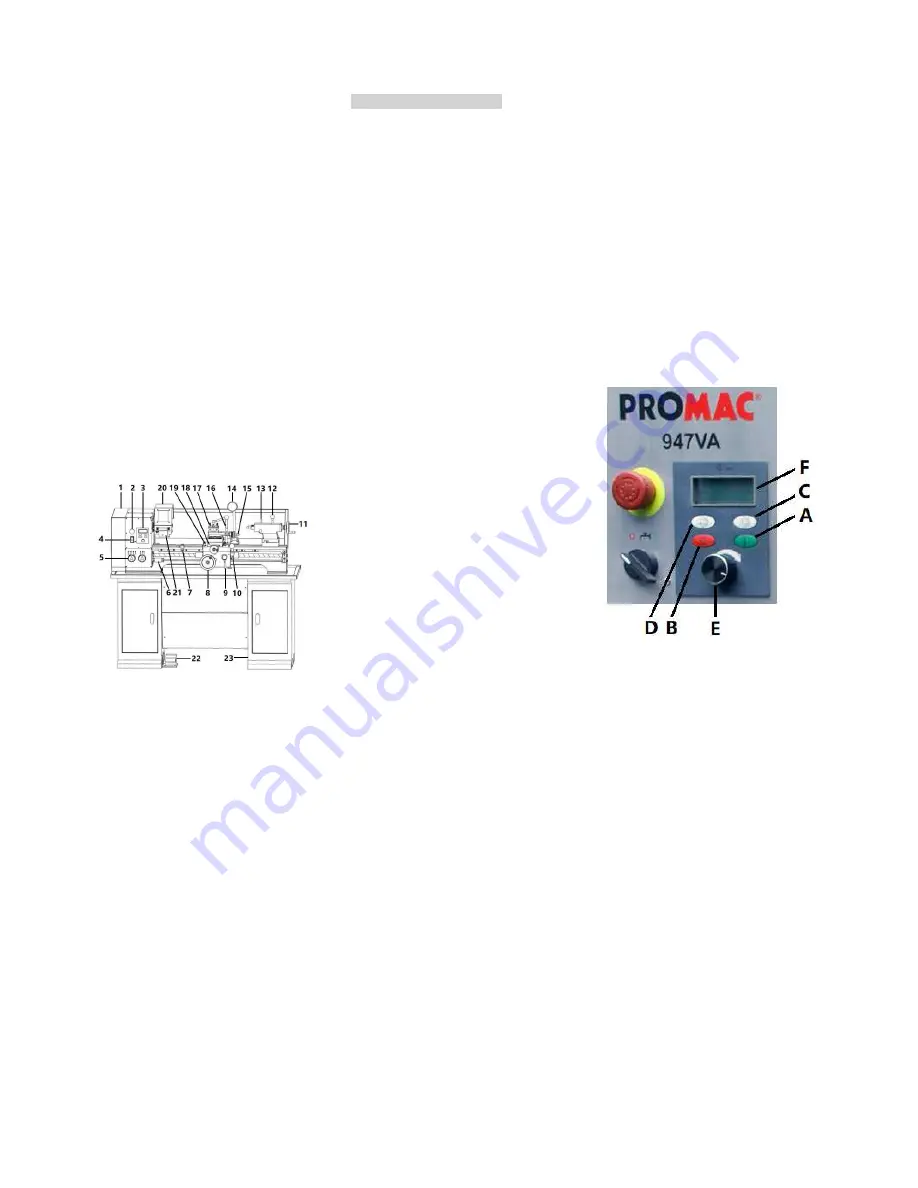

4.4 Machine Description

Fig 1

1…

Change Gear Cover

2…

Emergency Stop Switch

3… Control Panel

4…

Coolant pump switch

5… Feeding Selection Knob

6…

Clutch Overload

7… Stopping Plate

8… Carriage Handwheel

9… Half Nut Lever

10… Carriage/Cross Feed Lever

11…

Tailstock Barrel Handwheel

12…

Tailstock Clamp Lever

13…

Tailstock Center Lock

14…

Working Lamp

15… Compound Slide Handwheel

16… Coolant Hose

17…

Tool Post

18…

Cross Slide

19…

Carriage

20…

Chuck Guard

21… Lathe Chuck

22…

Foot Swhich

23…

Cabinet Stand

5. Transport and start up

5.1 Transport and installation

The machine will be delivered in a

closed crate.

For transport use a forklift or hand

trolley. Make sure the machine does

not tip or fall off during transport.

The machine is designed to operate in

closed rooms.

Make sure the machine cannot tip!

5.2 Assembly

If you notice transport damage while

unpacking, notify your supplier

immediately. Do not operate the

machine!

Dispose of the packing in an

environmentally friendly manner.

Clean all rust protected surfaces with

petroleum, diesel oil or a mild solvent.

Unbolt the lathe from the shipping

crate bottom.

Use heavy duty fibre belt for lifting the

machine off the pallet.

Caution:

The machine is heavy (387 kg)!

Assure the sufficient load capacity

and proper condition of your lifting

devices.

Never step underneath suspended

loads.

To avoid twisting the bed, make sure

the setup surface is absolutely flat and

level.

Loosen mounting bolts, shim and

tighten mounting bolts if needed.

The machine must be level to be

accurate.

5.3 Mains connection

Mains connection and any extension

cords used must comply with

applicable regulations.

The mains voltage must comply

with the information on the machine

licence plate.

The mains connection must have a

10 A surge-proof fuse.

Only use power cords marked

H07RN-F.

Connections and repairs to the

electrical equipment may only be

carried out by qualified

electricians.

5.4 Initial lubrication

The machine must be serviced at

all lubrication points before it is

placed into service!

Failure to comply may cause serious

damage.

(see chapter 8 for lubrication)

5.5 Starting operation

Before starting the machine check the

proper chucking (see chapter 6).

Always close the chuck guard and

pulley cover before you start the

machine.

You can start the machine with the

green ON-button (A, Fig 2).

The red OFF-button (B) stops the

machine.

The speed can be adjusted by turning

the switch (E).

Use buttons (C, D) to reverse the

spindle direction.

Fig 2

The RPM will be shown on the display

(F).

The emergency stop button (2, Fig 1)

stops all machine functions.

Turn emergency stop button clockwise

to reset.

Summary of Contents for 947VA

Page 26: ......