4

6. Machine operation

Warning:

Setup, maintenance and repair work

may only be carried out after the

machine is protected against

accidental starting by pulling the

mains plug.

Measurements and adjustments may

be carried out when the machine is at

a standstill only.

Check the save clamping of the work

piece before starting the machine.

Never stop the rotating chuck or work

piece with your hands.

Never place your fingers in a position

where they could contact any rotating

parts or chips.

Remove cutting chips with the aid of

an appropriate chip hook when the

machine is at a standstill only.

Always close the chuck guard and

pulley cover before you start the

machine.

Choose a small spindle speed when

working unbalanced work pieces and

for threading and tapping operations.

Never cut magnesium-

high danger to fire!

Measurements and adjustments may

be carried out when the machine is at

a standstill only.

In case of danger push the

emergency stop button.

6.1 Chucking

Never exceed the max speed

limitation of the work holding device.

Jaw teeth and scroll must always be

fully engaged. Otherwise chuck jaws

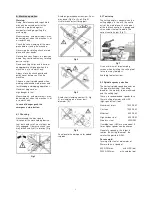

may break and fly off in rotation (Fig

3).

Fig 3

Avoid long workpiece extensions. Parts

may bend (Fig 4) or fly off (Fig 5).

Use tailstock or rest to support.

Fig 4

Fig 5

Avoid short clamping contact (A, Fig

6) or clamping on a minor part

diameter (B).

Fig 6

Face locate the workpiece for added

support.

6.2 Tool setup

The cutting angle is correct when the

cutting edge is in line with the centre

axis of the work piece. Use the point

of the tailstock centre as a gauge and

shims under the tool to obtain the

correct centre height (Fig 7).

Fig 7

Use a minimum of two clamping

screws when installing the cutting tool

to the four way tool post.

Avoid big tool extensions.

6.3 Spindle speeds selection

The correct spindle speed depends on

the type of machining, the cutting

diameter, the material to be machined

and the cutting tool.

These are recommended speeds for a

10mm cutting diameter with HSS

(high speed steel) tool:

Aluminium, brass 1500 RPM

Cast iron 1000 RPM

Mild steel 800 RPM

High carbon steel 600 RPM

Stainless steel 300 RPM

If carbide tools (HM) are used about 5

times higher speeds can be chosen.

Generally speaking, the larger in

relation the cutting diameter, the

smaller the possible RPM.

For example:

Turning mild steel at a diameter of

20mm allows a speed of

400 RPM max.

with HSS tool

2000 RPM max.

with carbide tool

Summary of Contents for 947VA

Page 26: ......