-35-

6.

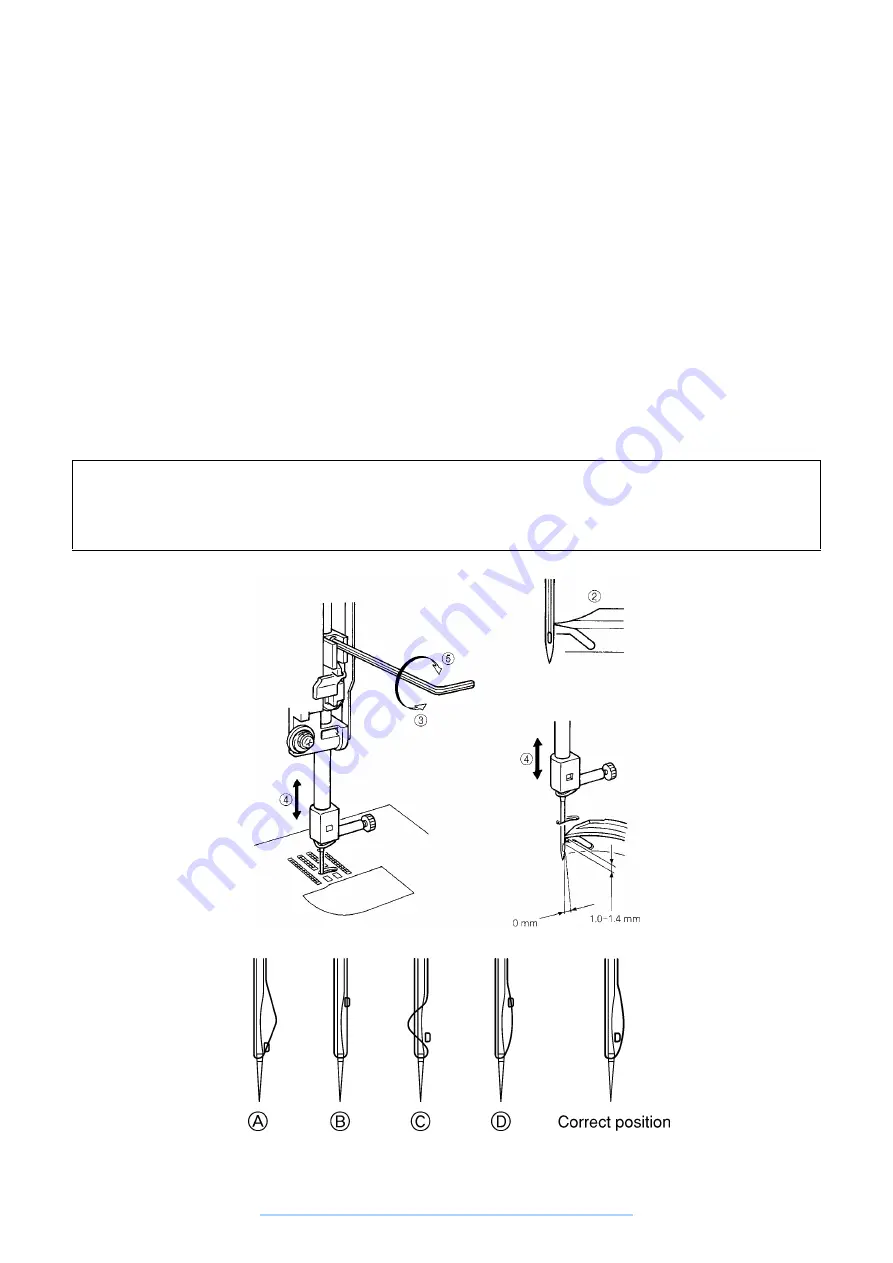

NEEDLE BAR HEIGHT

STANDARD

When test mode "5" is selected, turn the balance wheel so that the needle meets the rotary hook point. At this

time, the clearance between the upper end of the needle eye and the bottom of the rotary hook point should be

1.0-1.4 mm.

ADJUSTMENT

1.

Select test mode "5".

2.

Turn the balance wheel so that the needle meets the rotary hook point.

3.

Loosen the screw of the needle bar block assembly.

4.

Move the needle bar vertically to adjust the clearance to between 1.0-1.4 mm.

5.

Tighten the screw of the needle bar block assembly.

NOTE :The needle bar clamp should be parallel to the side of the needle plate. If the needle bar is loose

when you adjust the needle bar height, it may result in sewing troubles.

Adjustment Points

1.

If the needle bar height is too low or too high, skipped stitches, split thread or cut thread may occur. (Refer

to (A).)

2.

While adjusting the needle bar height, check the needle threading hook.

www.promelectroavtomat.ru

Summary of Contents for M3000C

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM www promelectroavtomat ru ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART www promelectroavtomat ru ...

Page 13: ... 11 www promelectroavtomat ru ...

Page 17: ... 15 www promelectroavtomat ru ...

Page 19: ... 17 www promelectroavtomat ru ...

Page 25: ... 23 2 LEAD WIRE ARRANGEMENT www promelectroavtomat ru ...

Page 67: ...ULT2003D S G 3100D ULT2001N ULT2001C M3000N M3000C 11C03HF114200 www promelectroavtomat ru ...