-56-

27.

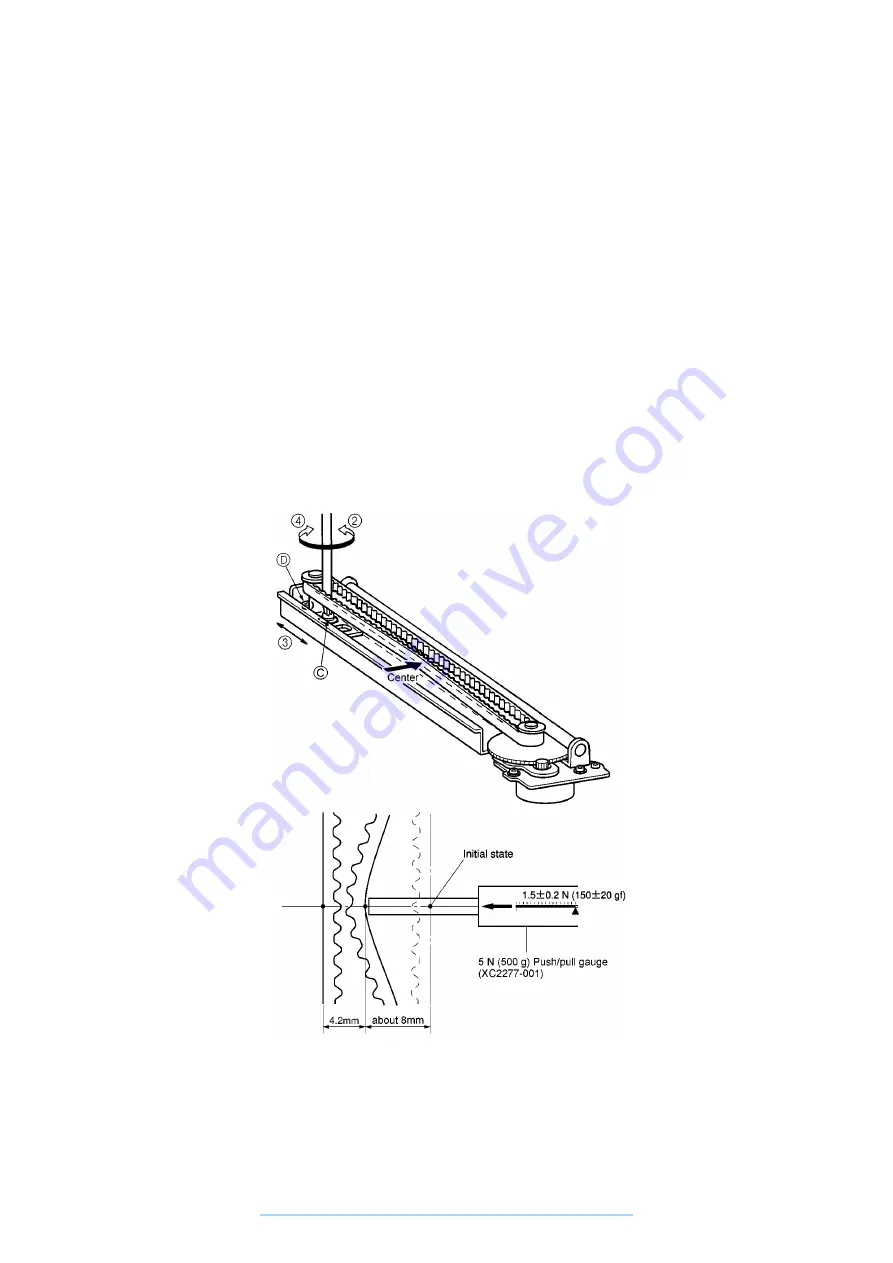

TIMING BELT TENSION FOR THE Y DIRECTION

STANDARD

The distance between the backs of both sides of the timing belt should be 4.2 mm (about 8 mm of slack)

as shown in the diagram and there should be a load of 1.5±0.2 N (150±20 gf) after the Y carriage is moved

all the way forward and a 5 N (500 g) push/pull gauge is applied to the center of the timing belt between

the Y drive shaft and the Y tension pulley.

ADJUSTMENT

1.

Move the Y carriage all the way forward.

2.

Loosen the screw of the Y tension pulley.(screw (C) and (D))

3.

Adjust the position of the Y tension pulley.

4.

Tighten the screw of the Y tension pulley.(screw (C) and (D))

CHECK STANDARD

The product standard, taking any measurement errors into account, is between 0.7 N and 1.7 N (70 g and

170 g).

www.promelectroavtomat.ru

Summary of Contents for M3000C

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM www promelectroavtomat ru ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART www promelectroavtomat ru ...

Page 13: ... 11 www promelectroavtomat ru ...

Page 17: ... 15 www promelectroavtomat ru ...

Page 19: ... 17 www promelectroavtomat ru ...

Page 25: ... 23 2 LEAD WIRE ARRANGEMENT www promelectroavtomat ru ...

Page 67: ...ULT2003D S G 3100D ULT2001N ULT2001C M3000N M3000C 11C03HF114200 www promelectroavtomat ru ...