Maintenance manual Universal-1000

P R O M E T A L

21

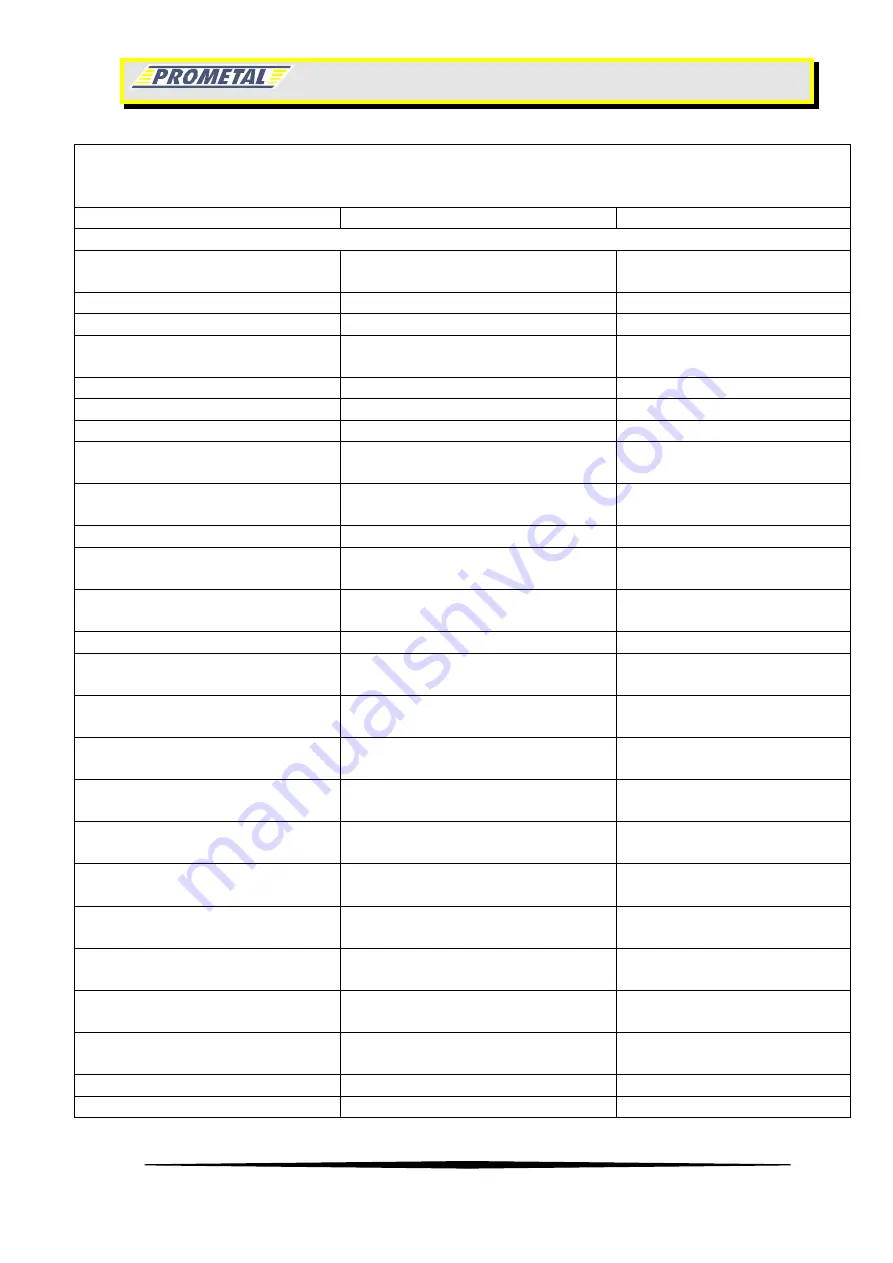

Weekly maintenance (every 50 hours)

Part

Point of maintenance

Maintenance activity

Safety related screwed connection

e.g. swivel heads,pedestal bearings

Checking the tight fit of

screws and nuts

De-moulding cylinder

Swivel heads, push rods

Lubricating, cleaning

Tamper head cylinder

Pedestal bearings, swivel heads

lubricating

Tamper head cylinder

Bearings, push rods

Checking the tight of screws,

cleaning

Machine

Guiding columns

Checking and cleaning

Synchron bars

Sprocketwheels, synchron chains

Lubricating, cleaning

Tamper head brake

Brake bars, brake linings

Checking and cleaning

Tamper head safety bolt

Checking condition and

presence

Tamper head

Tamper head vibrators

Checking the tight fit of

screws

Tamper head

Rubber buffers

Checking the condition

Mould guide/clamping

Bearings, rubber buffers, moulder

stoppers

Lubricating, checking and

cleaning

Vibrator table

Wear ledges and impact bars

Checking distance and

parallelism

Vibrator table

Rubber buffers

Checking the condition

Rocker arms

Bearings, hydraulic cylinder

Lubricating, checking the

tight fit of screws

Filler box/agitator cart

Stripper brush

Checking the tight fit of

screws

Agitator cart

Crank arm drive, hydraulic cylinder

Checking the tight fit of

screws

Agitator

Profiles, screws, distance

Checking the tight fit of

screws

Table plate

Clamping

Checking the tight fit of

screws

Cocnrete hopper

Crank arm, hopper flaps

Checking the tight fit of

screws, lubricating

Pallet transport

Latches, wheels and wheel paths

Checking, cleaning,

lubricating

Pallet transport

Guide pulley, drive chain

Lubricating, checking the

chain tension

Lifting device

Rocker bearings, flange rollers

Lubricating, checking the

tight fit of lock nuts, cleaning

Mould change cart

Flange bearings

Checking the tight fit of

screws

Hydraulic unit

Vis. clogging indicator/press. filter

Checking

Hydraulic unit

Vacuum indicator/air breather unit

Checking

Summary of Contents for UNIVERSAL 1000

Page 19: ...Maintenance manual Universal 1000 P R O M E T A L 19 ...

Page 25: ...Maintenance manual Universal 1000 P R O M E T A L 25 Hydraulic system ...

Page 26: ...Maintenance manual Universal 1000 P R O M E T A L 26 ...

Page 52: ...Maintenance manual Universal 1000 P R O M E T A L 52 Now lower down tamper head and mould ...

Page 53: ...Maintenance manual Universal 1000 P R O M E T A L 53 Pull out cart with mould on itself ...

Page 58: ...Maintenance manual Universal 1000 P R O M E T A L 58 After adjustment is done ...

Page 65: ...Maintenance manual Universal 1000 P R O M E T A L 65 Vibrator table maintenance ...