Maintenance manual Universal-1000

P R O M E T A L

22

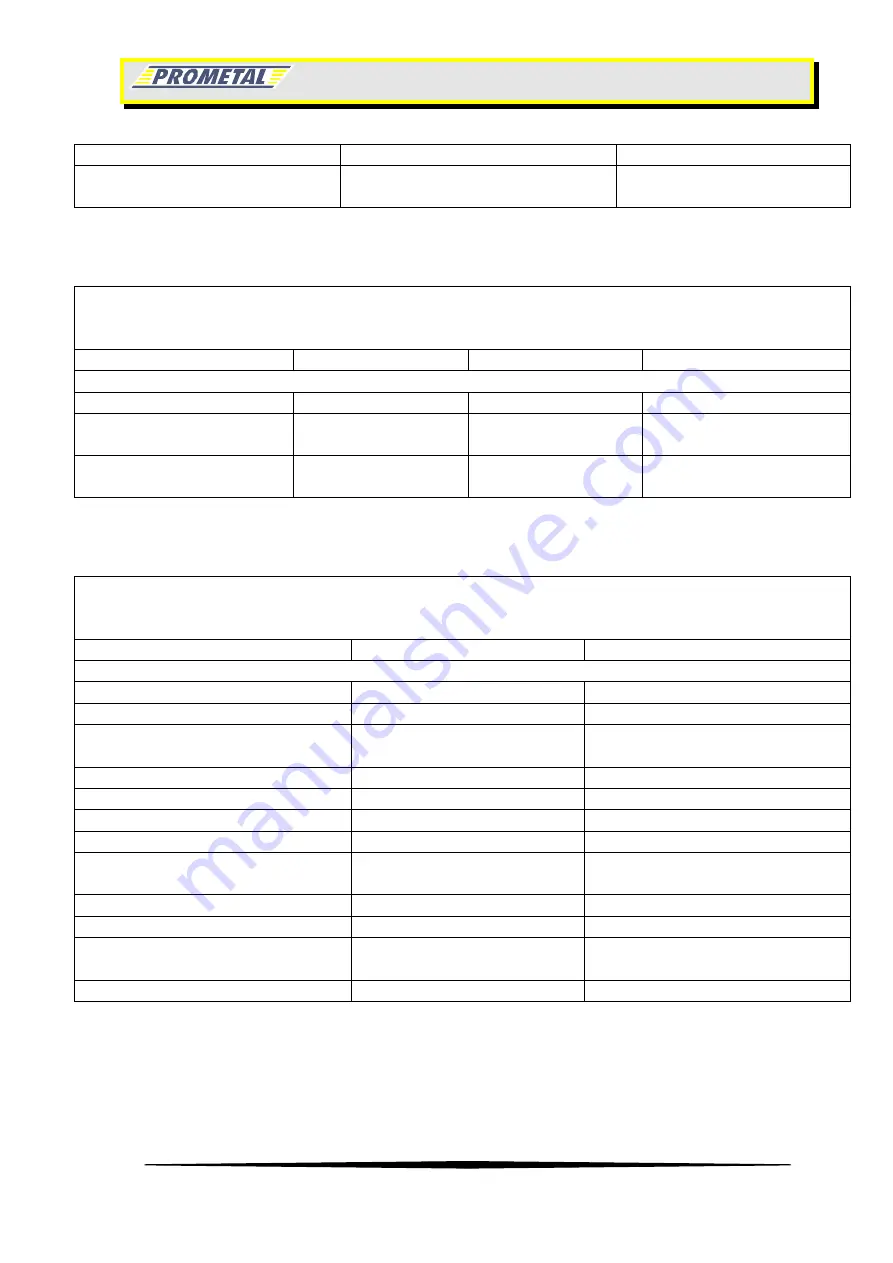

Hydraulic unit

Possible drippings and leakages

Checking

Valve bank, accumulator

Electronic pressure sensor

Checking hydraulic control

oil pressure

Vibrator table maintenance

Part

Point of maintenance

Maintenance activity

Interval

Vibrator table

Bearings

Lubricating

Every 40 hours

Vibrator table

Bearing covers

Checking the tight fit

of screws

Every 200 hours

Vibrator table

Flanges

Checking the tight fit

of screws

Every 200 hours

Monthly maintenance (every 200 hours)

Part

Point of maintenance

Maintenance activity

Motors

Electrical connections

Checking the tight fit

Tamper head brake

Brake linings

Checking the thickness

Tamper head cross stripper brush

Bearings, sprocket wheel,

columns

Checking, lubricating, cleaning

Tamper head cross stripper brush

Chain tension

Checking, adjust if necessary

Charging frame

Lifting spindles

Checking for wear

Charging frame

Guide, columns, locking

Checking, cleaning

Agitator cart

Crank arm drive

Checking for backlash

Agitator cart; hydraulic cylinder

Swivel head, pedestial

bearing

Lubricating

Stripper frame

Checking for wear

Lifting device

Flange rollers

Checking, cleaning

Mould change cart

Bearings, fl.rollers, sprocket

wheels

Lubricating, checking, cleaning

Hydraulic unit

Oil cooler

Clearing

Summary of Contents for UNIVERSAL 1000

Page 19: ...Maintenance manual Universal 1000 P R O M E T A L 19 ...

Page 25: ...Maintenance manual Universal 1000 P R O M E T A L 25 Hydraulic system ...

Page 26: ...Maintenance manual Universal 1000 P R O M E T A L 26 ...

Page 52: ...Maintenance manual Universal 1000 P R O M E T A L 52 Now lower down tamper head and mould ...

Page 53: ...Maintenance manual Universal 1000 P R O M E T A L 53 Pull out cart with mould on itself ...

Page 58: ...Maintenance manual Universal 1000 P R O M E T A L 58 After adjustment is done ...

Page 65: ...Maintenance manual Universal 1000 P R O M E T A L 65 Vibrator table maintenance ...