Maintenance manual Universal-1000

P R O M E T A L

41

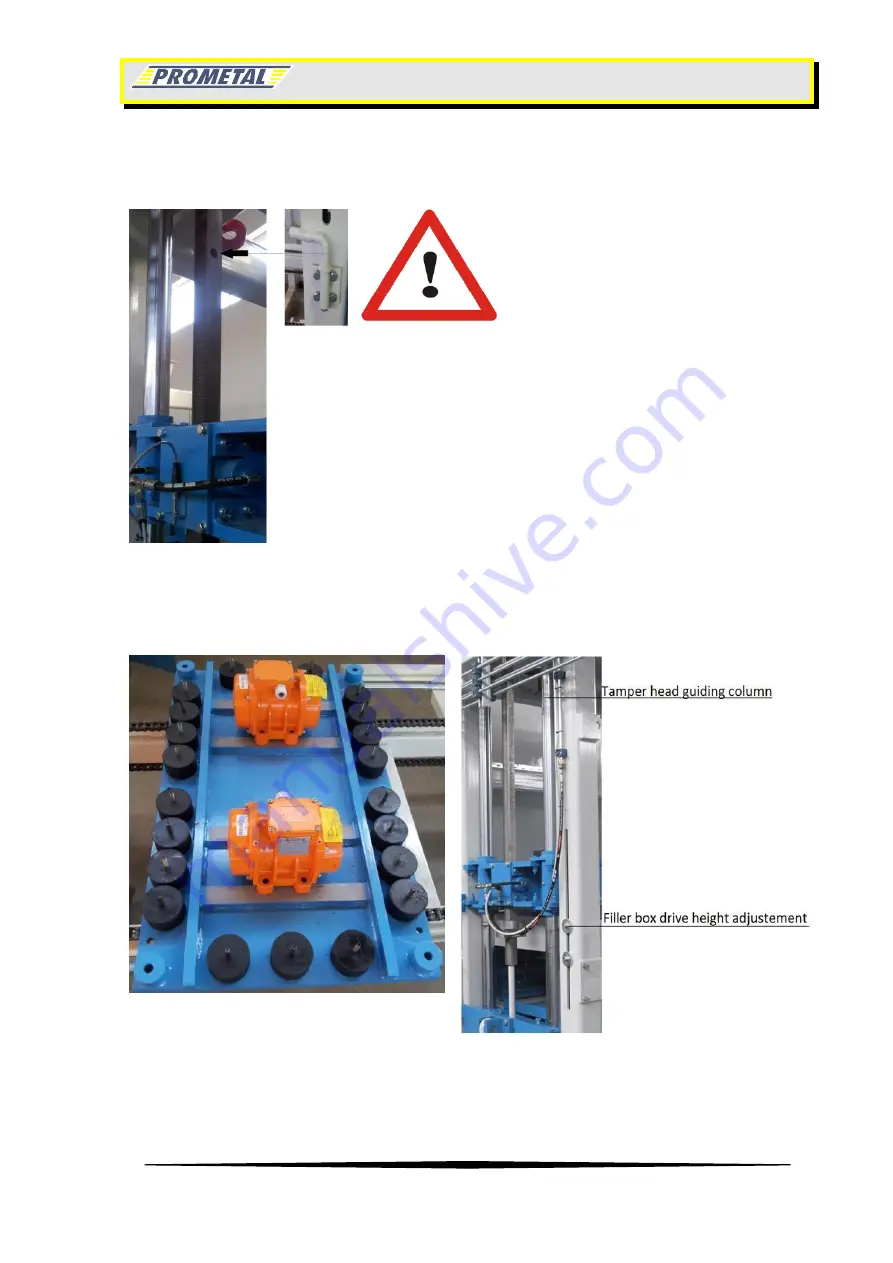

Tamper head maintenance

Warning!

When some maintenance work is carried out on the

tamper head guide bridge, tamper head main plate or

tamper head itself the stopcocks must be closed and the

retaining bolts for securing the tamper head must be in

position!

Also control voltage must be switched off!

Machine that are equipped

with tamper head vibration,

the tamper head and tamper head

plate respectively are connected with the guide bridge by means of rubber buffers.

Tamper head bridge carrier.

Summary of Contents for UNIVERSAL 1000

Page 19: ...Maintenance manual Universal 1000 P R O M E T A L 19 ...

Page 25: ...Maintenance manual Universal 1000 P R O M E T A L 25 Hydraulic system ...

Page 26: ...Maintenance manual Universal 1000 P R O M E T A L 26 ...

Page 52: ...Maintenance manual Universal 1000 P R O M E T A L 52 Now lower down tamper head and mould ...

Page 53: ...Maintenance manual Universal 1000 P R O M E T A L 53 Pull out cart with mould on itself ...

Page 58: ...Maintenance manual Universal 1000 P R O M E T A L 58 After adjustment is done ...

Page 65: ...Maintenance manual Universal 1000 P R O M E T A L 65 Vibrator table maintenance ...