Maintenance manual Universal-1000

P R O M E T A L

64

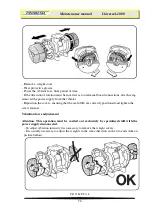

Mould and tamper head mounting on machine frame

Mounting of mould and tamper head is going in opposite way from dismantling.

-tight vibrators on mould

-tight mould to machine frame, rubber buffers must be aligned well between mould and

mould clamping device

–

without distortion

-check that tamper head shoes are well centered in mould body

-tight well screws that fixes tamper head to tamper head bridge

-check the electric cables and connectors for vibrators and if they are not damaged, plug them

in

These instructions are valid for all mould types.

Summary of Contents for UNIVERSAL 1000

Page 19: ...Maintenance manual Universal 1000 P R O M E T A L 19 ...

Page 25: ...Maintenance manual Universal 1000 P R O M E T A L 25 Hydraulic system ...

Page 26: ...Maintenance manual Universal 1000 P R O M E T A L 26 ...

Page 52: ...Maintenance manual Universal 1000 P R O M E T A L 52 Now lower down tamper head and mould ...

Page 53: ...Maintenance manual Universal 1000 P R O M E T A L 53 Pull out cart with mould on itself ...

Page 58: ...Maintenance manual Universal 1000 P R O M E T A L 58 After adjustment is done ...

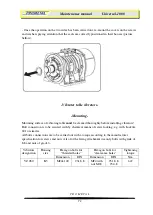

Page 65: ...Maintenance manual Universal 1000 P R O M E T A L 65 Vibrator table maintenance ...