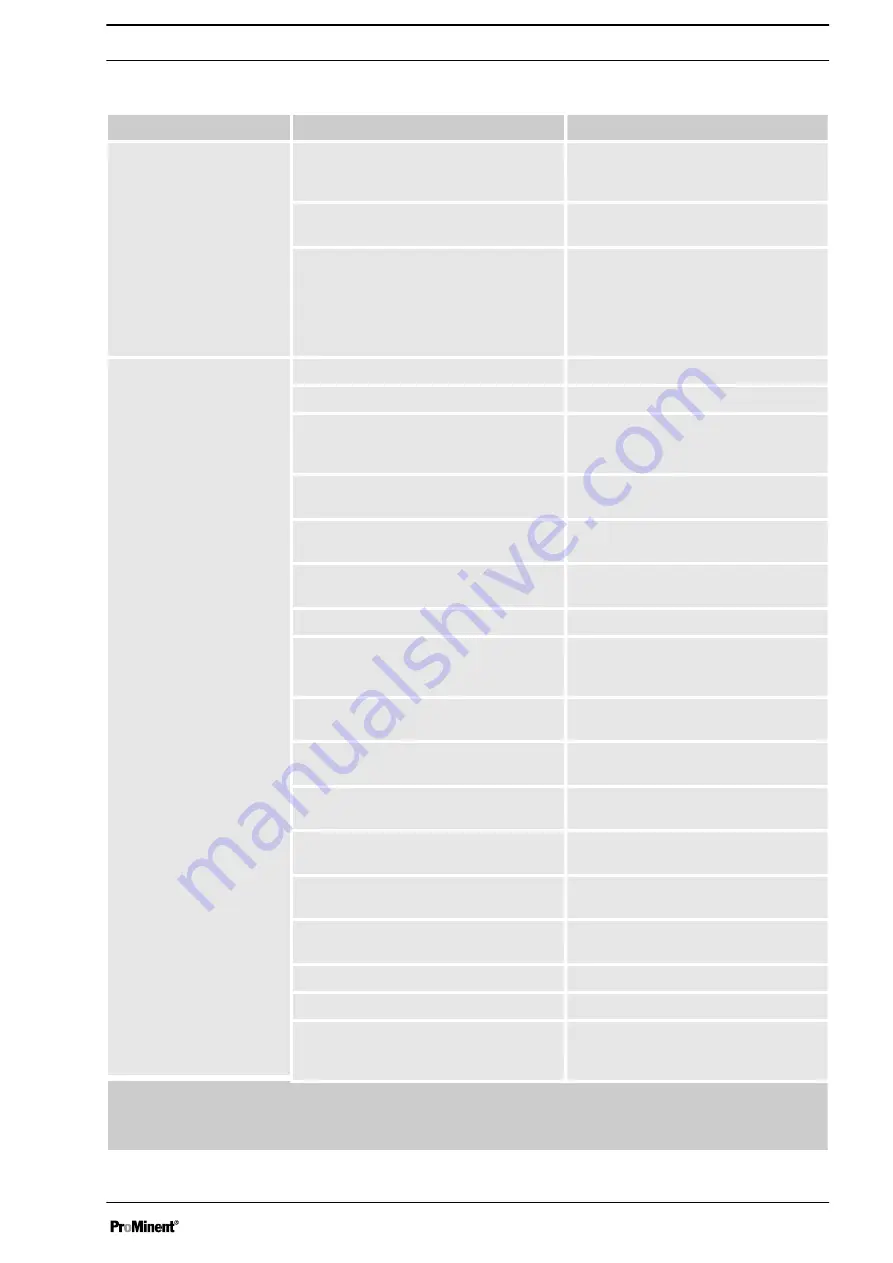

7.2 Troubleshooting

Fault

Possible cause

Remedy

Suction line contains gas

bubbles

Priming lift too high, operating condi‐

tions too close to the vapour pressure

of the medium

Reduce priming lift, use automatic

gas release, reduce temperature

Suction line leaks and is drawing air

Check negative pressure tightness

and connections, bleed line

Medium tends to be gaseous

Automatic gas release at the highest

point and in the dosing head, always

lay suction lines at a continuous

incline, avoid higher temperatures

and UV radiation, flush suction con‐

nector

Metering pump is not

pumping or indicates

decreased capacity

Suction line contains gas bubbles

See separate fault indication

Suction line is blocked

Remove blockage / dirt

Suction pressure required is too high

Modify suction line, use a wider

cross-section and/or use a priming

pulsation damper

Suction line contains gas bubbles

Bleed at the highest point, lay suction

line with a continuous incline

Flushing or drain open on the suction

side

Close flushing or drain tap on the

suction side

Shut-off valve on the evacuation tank

not closed

Close fitting and, if required, re-evac‐

uate the suction line

Tank and/or priming lift too high

Use priming aid

Empty alert and/or low flow contact trig‐

gered

Top up chemicals into the storage

tank: make sure that the level sensor

is immersed in the medium

Ball jammed/stuck in the metering

pump suction or discharge valve

Dismantle, clean and, if required,

replace valve

Ball dissolved in the suction or dis‐

charge valve

Replace valve and check resistance

Diaphragm tear / diaphragm rupture

sensor activated

Replace diaphragm and sealing set

Opening pressure of the relief valve /

safety valve too low

Correctly set the opening pressure

Open flushing and drainage connection

on the discharge side

Close flushing and drainage connec‐

tion

Air in the discharge line

Bleed metering line at the highest

points

Metering line ruptured

Correctly repair the metering line

Shut-off valve closed (discharge side)

Open shut-off valve

Metering line blocked

Rectify blockage, check opening

pressure of the relief valve and/or

safety valve

The table does not claim to be complete.

Further reasons for failure and detailed information on the causes of faults can be found in the operating

instructions for the individual components.

Maintenance and Troubleshooting

31