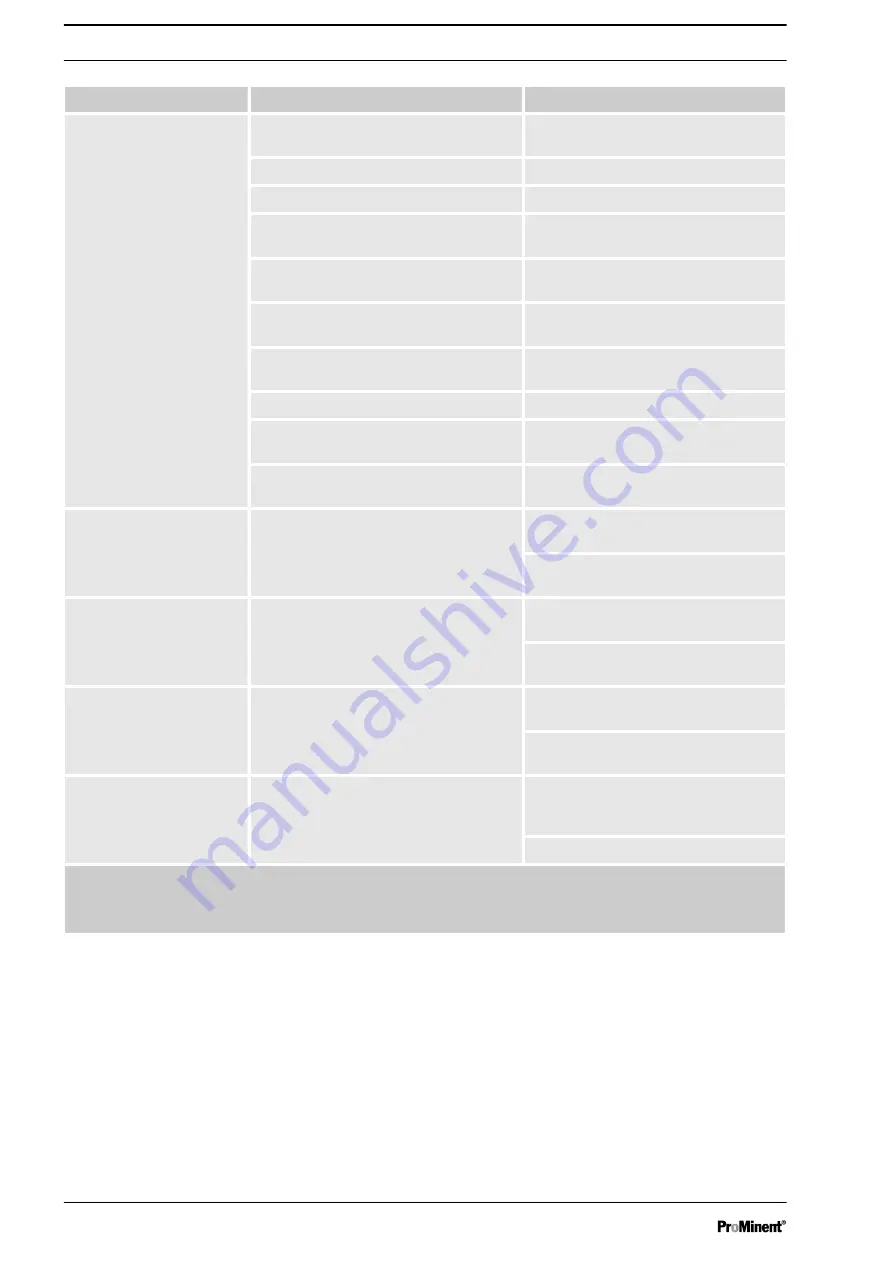

Fault

Possible cause

Remedy

Back pressure too high at the injection

point

Reduce back pressure or replace

pump with a higher capacity

Injection point blocked

Clean injection point

Voltage drop or failure

Reconnect the power supply

Cable for power supply is not correctly

connected

Ensure correct power supply through

measurement

Control failure, no control signal

Ensure correct control signal through

measurement

Cable for control is loose or incorrectly

connected

Check connector and, if required,

rewire the signal cable

Stroke rate or stroke length set to "0"

Set the stroke rate / stroke length to

the desired value

Pump is set to standby mode or pause Check the control or pause signal

Faulty operation of the pump/metering

system

Train operating staff

Electrical connection malfunctioning

Check the contacts for corrosion and

secure fixing

Display on the pressure

manometer pulsates

Pulsation damper pre-load is incorrect

Check the setting of the pulsation

damper

Retrofit pulsation damper if neces‐

sary

Discharge line displays

strong vibrations or starts

"pulsating'

Pressure peaks too high

Check the setting of the pulsation

damper

Retrofit pulsation damper if neces‐

sary

Suction line displays

strong vibrations or starts

"pulsating'

Pressure peaks too high

Check the setting of the pulsation

damper

Retrofit pulsation damper if neces‐

sary

Fluid is leaking from the

backplate of the metering

pump

Liquid end not tight

Tighten the screws on the dosing

head crosswise to the correct tight‐

ening torque

Replace diaphragm/sealing set

The table does not claim to be complete.

Further reasons for failure and detailed information on the causes of faults can be found in the operating

instructions for the individual components.

Maintenance and Troubleshooting

32