Pr

o

Minent

®

Page 24

Commissioning

8

Commissioning

WARNING

•

Protect yourself from contact with hazardous feed chemicals!

•

Remove all water from liquid end before commissioning or rinse out with a

suitable material if using chemicals that should not come into contact with

water! (Proceed as described below. The liquid end may contain water left

over from factory testing.)

•

After long periods out of commission the gamma/ L is not guaranteed to

meter absolutely reliably, as feed chemicals in the valves and diaphragm can

crystallise! Check valves and diaphragm regularly (see section 10)!

•

Check the seals of the pump connections and connectors.

•

Check whether coarse or fine bleed vent is closed (see also fine bleed

function).

GUIDELINE

•

Set stroke length only while pump is running!

•

The gamma/ L should prime at 100 % stroke length as the suction lift is

dependent upon lift volume when the liquid end is empty. If the gamma/ L is

required to prime at less than 100 % stroke length, and fails to do so, then select

a correspondingly smaller suction lift.

•

SEK type: priming capacity is diminished if discharge takes place against

pressure!

•

Retighten screws in liquid end after 24 hours (see section 10)!

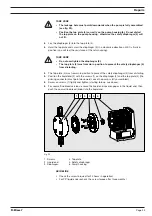

Removing water from

liquid end

When using with chemicals that should not come into contact with water:

S

Turn the pump so that the discharge connector is pointing downwards.

S

Allow water to run out of the liquid end.

S

Rinse the suction connector from above with a suitable material.

Filling liquid end

WARNING

Protect yourself from contact with hazardous feed chemicals!

For liquid ends without coarse/fine bleed function:

S

Connect suction tubing, but not discharge tubing, to liquid end

S

Switch on the gamma/ L and allow to run at maximum stroke length and stroke rate, until

the liquid end is full and free from air bubbles (a little feed chemical will seep out of the

discharge valve)

S

Switch off the gamma/ L

S

Connect discharge tubing to liquid end

The gamma/ L is ready to operate.

For liquid ends with coarse/fine bleed function:

S

Connect suction and discharge tubing to liquid end

S

Connect bypass tubing

S

Open the bleed valve by rotating the knob on the top anticlockwise. Opens access to the

bypass tubing for coarse bleed function.

S

Switch on the gamma/ L and allow to run at maximum stroke length and stroke rate, until

the liquid end is full and free from air bubbles (the feed chemical is visible in the bypass and

discharge tubing)

S

Close the bleed valve (turn clockwise)

S

Switch off the gamma/ L

The gamma/ L is ready to operate.