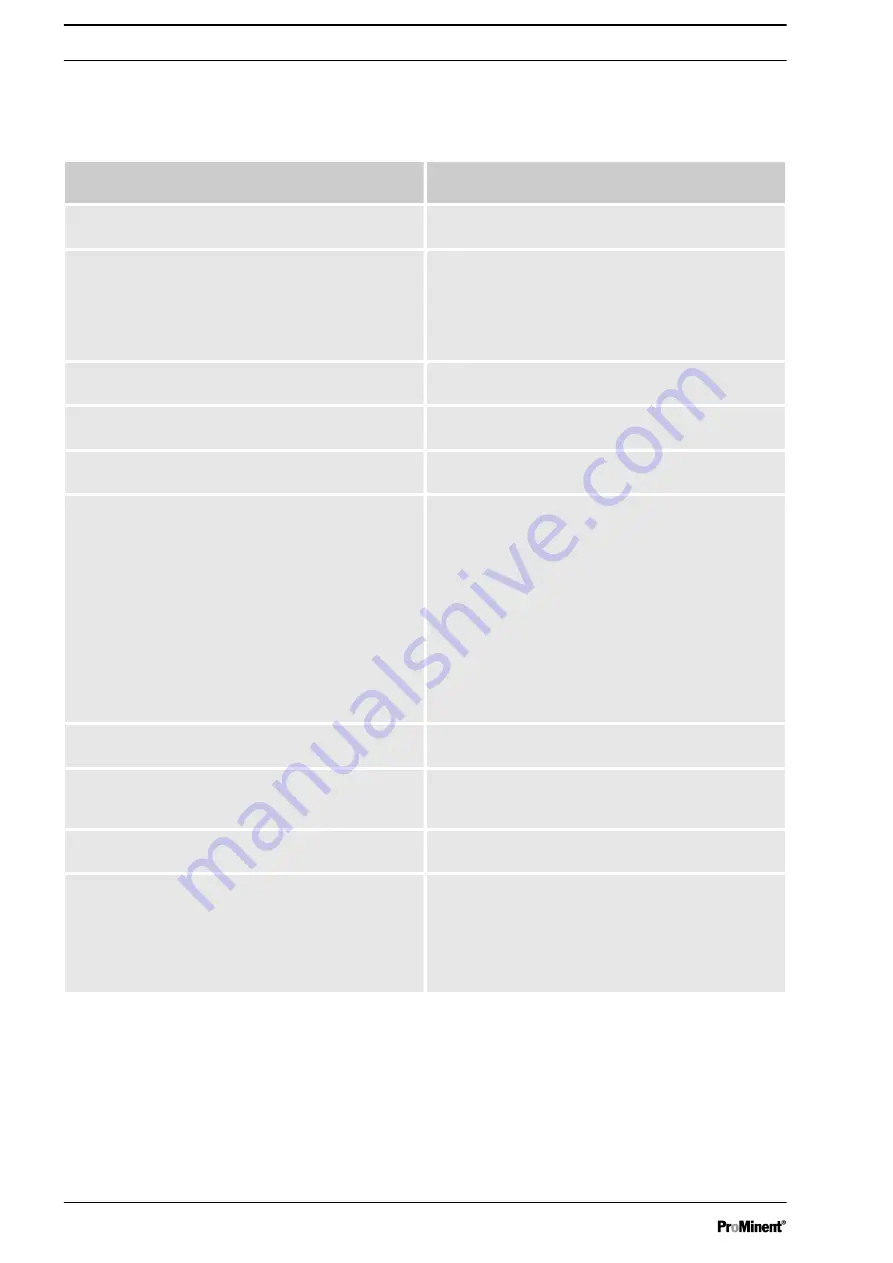

Ignition hazard

Protective measures to be observed by the cus‐

tomer

Excessive surface pressure

Limitation of the maximum temperature of the feed

chemical

Pump running hot

The customer must monitor and maintain the pump

in accordance with the “Maintenance” chapter.

The customer must monitor the capacity.

The customer must fit a relief valve on the discharge

side.

Mechanically generated sparks from the mechanism

with low oil

The customer must monitor and maintain the pump

in accordance with the “Maintenance” chapter.

Electrical stray current in the event of a short circuit

The customer must earth the pump and maintain the

earthing of the individual components.

Electrical stray current in the event of a lightning

strike

The customer must put in place measures in accord‐

ance with EN 1127-1, if necessary.

Static electricity

The customer must earth the earthing points and

maintain the potential equalisation cables of the indi‐

vidual components.

The customer must pay attention to potential equali‐

sation when dismantling.

Paint should not be applied too thickly.

Dosing heads made of electrically non-conductive

materials must not be used.

The customer must wire the diaphragm rupture indi‐

cator in such a way that it immediately stops the

pump.

Electromagnetic waves (also lasers), ionising radia‐

tion and ultrasound have an impact on the pump

The customer must put in place measures in accord‐

ance with EN 1127-1, if necessary.

Adiabatic compression and shock waves

Non-conductive feed chemicals: Do not allow the

unit to run dry – even when filling and emptying the

liquid end.

Deposits of dust

Regularly clean the outside of the pump with a damp

cloth.

Flammable feed chemicals

The pump must only be allowed to meter flammable

feed chemicals with electrically well-conducting

dosing heads.

Make sure that the diaphragm rupture indicator

stops the pump immediately in the event of a dia‐

phragm rupture.

Summary of relevant ignition hazards

and protective measures put in place

for the Makro TZ in accordance with

EN ISO 80079-36

Safety chapter

16