* for measurements taken under constant conditions, minimum

30% stroke rate and water at 20 °C - when installed correctly, p< 1

bar

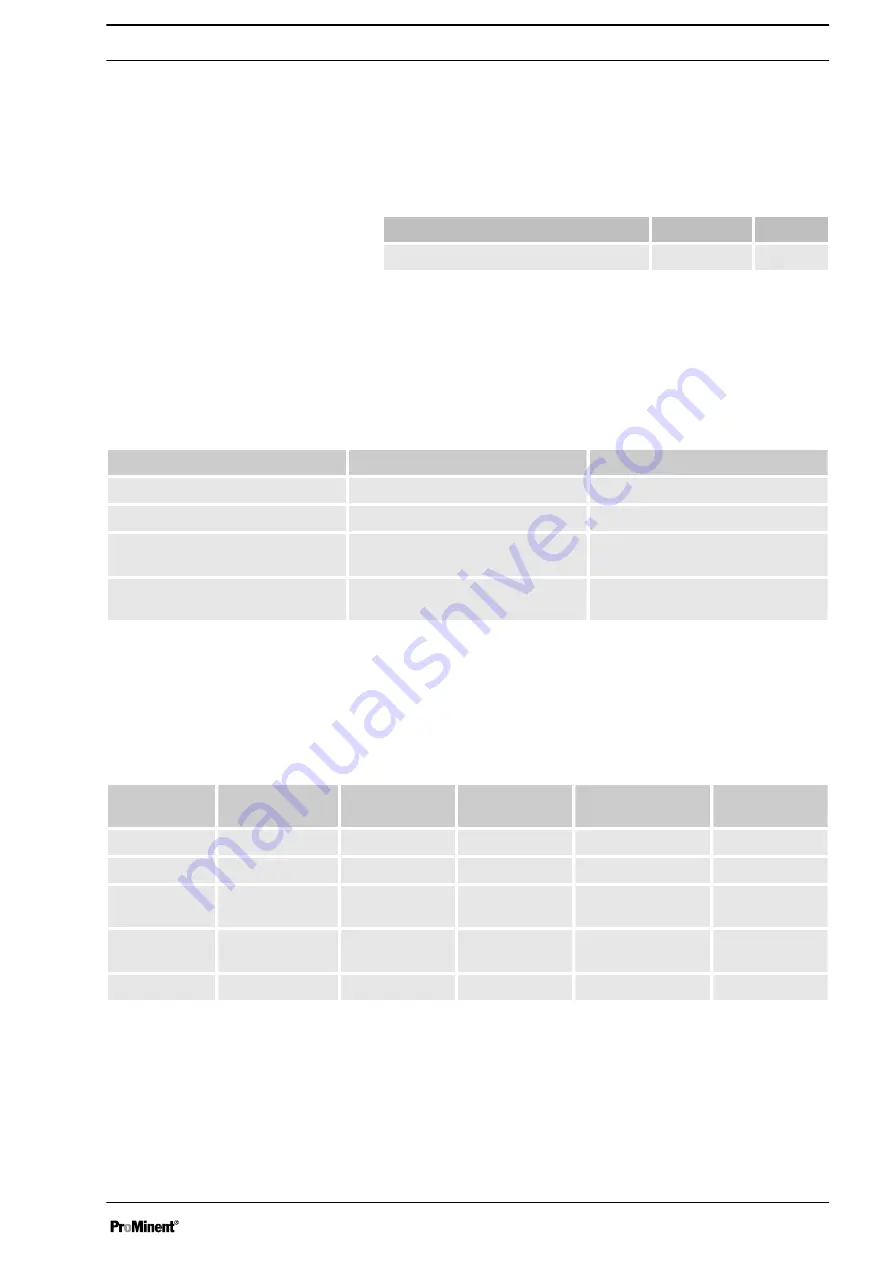

13.2.2 Dosing precision

Data

Value Unit

Dosing precision

±1 % *

* at maximum stroke length and maximum back pressure

13.3 Viscosity

The liquid ends are generally suitable for the following viscosity

ranges:

Design

Area

Unit

no valve springs

0 ... 200 mPas

with valve springs

200 ... 500 mPas

with appropriately laid out installa‐

tion

500 ... 1000 mPas

with appropriately laid out installa‐

tion and advice from ProMinent

over 1000 mPas

* Only when the installation is correctly adjusted.

13.4 Wetted materials

Tab. 4: with DN 25 ball valve

Material ver‐

sion

Liquid end

Suction/pres‐

sure connector

Seals

Valve balls

Valve seat

PPT

Polypropylene

PVDF

PTFE

Borosilicate glass

PTFE

PCT

PVC

PVDF

PTFE

Borosilicate glass

PTFE

TTT

PTFE with

carbon

PTFE with

carbon

PTFE

Ceramic

PTFE

SST

Stainless steel

1.4571/1.4404

Stainless steel

1.4571/1.4404

PTFE

Stainless steel

1.4401

PTFE

HCT

Hastelloy C4

Hastelloy C4

PTFE

Ceramic

PTFE

Technical data

75