Promix-SM306

2

Check completeness of the lock set when buying! After buying, the

manufacturer will not accept claims related to incomplete set.

3.

SET OF DELIVERY

4.

DESIGN AND PRINCIPLE OF OPERATION

The locks are produced in two versions: normally opened (NO), and normally closed (NC).

NO lock is in the open state when de-energized and in the closed state when voltage is supplied.

NC lock is in the closed state when no voltage is supplied, and in the open state when the lock is

energized. For opening the lock, it is necessary to de-energize a normally open lock or to supply

voltage to a normally closed lock.

The lock is mounted at any place at the door ledge, and the latch is mounted on the door. The

possibility of mechanical deblocking is provided for emergency opening of the lock.

A protective shutter for preventing unauthorized opening of the lock is provided in the lock

design (optional).

Adjustment holes on the adjustment plate serve for

correcting the latch roller position relative to the snap channel

in the vertical direction (e.g., in case of the door sagging) and

in the horizontal direction.

As the door is closed, the latch enters the slot in the lock

and, overcoming the catch hook force, is fixed transferring the

catch hook from “open” position to “closed” position. As

supply voltage is applied (or, for a normally closed version, as

the lock is de-energized), the catch hook is blocked in the

"closed" position and locks the latch.

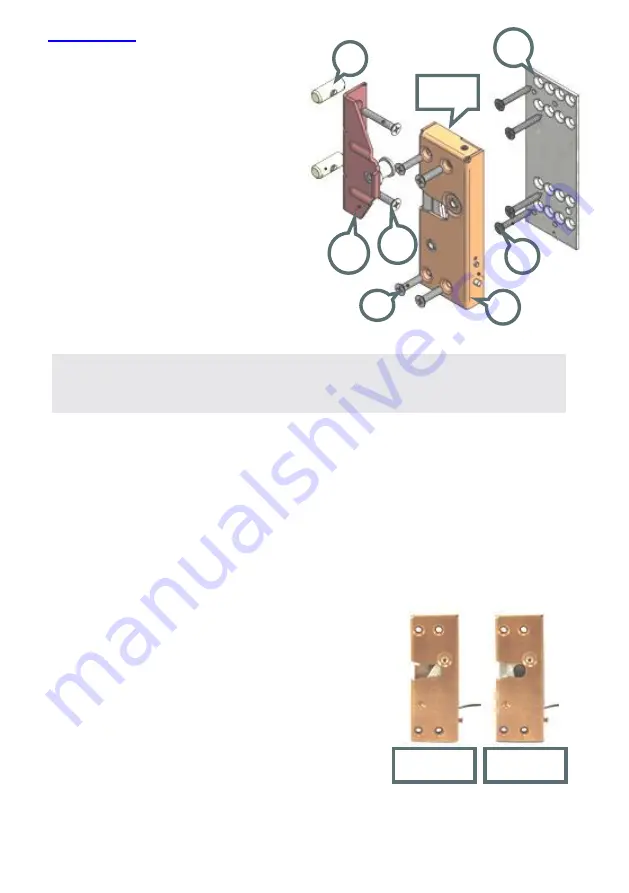

1

– Lock

1 pc.

2

– Latch

1 pc.

3

–Adjustment plate

(in the as-delivered condition,

screwed to the lock with screws 4)

1 pc.

4

– Screw М4х16 (countersunk)

4 pcs.

5

– Screw М6x25 (countersunk)

2 pcs.

6

– Self-tapping screw 3.5х30

(countersunk)

4 pcs.

7

– Barrel nut

2 pcs.

8

– Self-tapping screw 5.5х32

(countersunk)

2 pcs.

9

– Plug

2 pcs.

10

– Angular template

1 pc.

11

– Operating manual

1 pc.

.

4

5

1

2

3

6

7

Base

edge

“Open”

position

“Closed”

position