6

The lock does not need lubrication!

7.

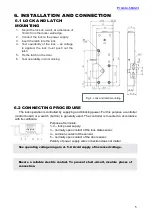

FEATURES OF INSTALLATION AND

OPERATION

1) The possibility of using the lock and the place of installation (outdoors or indoors) are

determined by

the

installation

organization

on the basis of the design features and the lock

operating principle, method of installation, room criticality level, the purpose of the access

restriction regime and other factors (the presence of security providers, video surveillance,

etc.).

2) To prevent deformations of the door due to attempts to open the door with the lock closed, it is

recommended to mount the lock in the area of the door handle.

8.

POTENTIAL MALFUNCTIONS

Malfunctions and problems

Remedies

The lock does not fix the latch (the door is

not fixed in the closed state).

Check the absence of supply voltage.

Adjust the latch position so that the latch, with the

door closed, enters the lock slot until the catch

hook operates.

The latch does not enter the lock slot, or

enters with friction.

Restore position of the door that changed in the

course of operation. If restoration is impossible,

adjust the latch.

9.

MAINTENANCE

Maintenance of the lock is performed at least once every two months and includes:

Visual inspection of the lock to check the reliability of the fastening. If necessary, tighten

the fasteners of the lock and the latch.

Checking the proper position of the latch.

10.

STORAGE AND TRANSPORTATION

Prior to putting into operation, the locks must be stored in the manufacturer’s packing, in

rooms with an ambient temperature

of -30 to +50

°С

and a relative humidity not higher than 98 %

at 25

ºС in compliance with storage conditions as per GOST 15150-69.

Locks transportation conditions must comply with group C as per GOST 23216-78 in terms of

exposure to mechanical factors, and Ж2 as per GOST 15150-69 in terms of exposure to climatic

factors.