PUV-3600HD / PUV-4000HD

SECTION 4

4.14

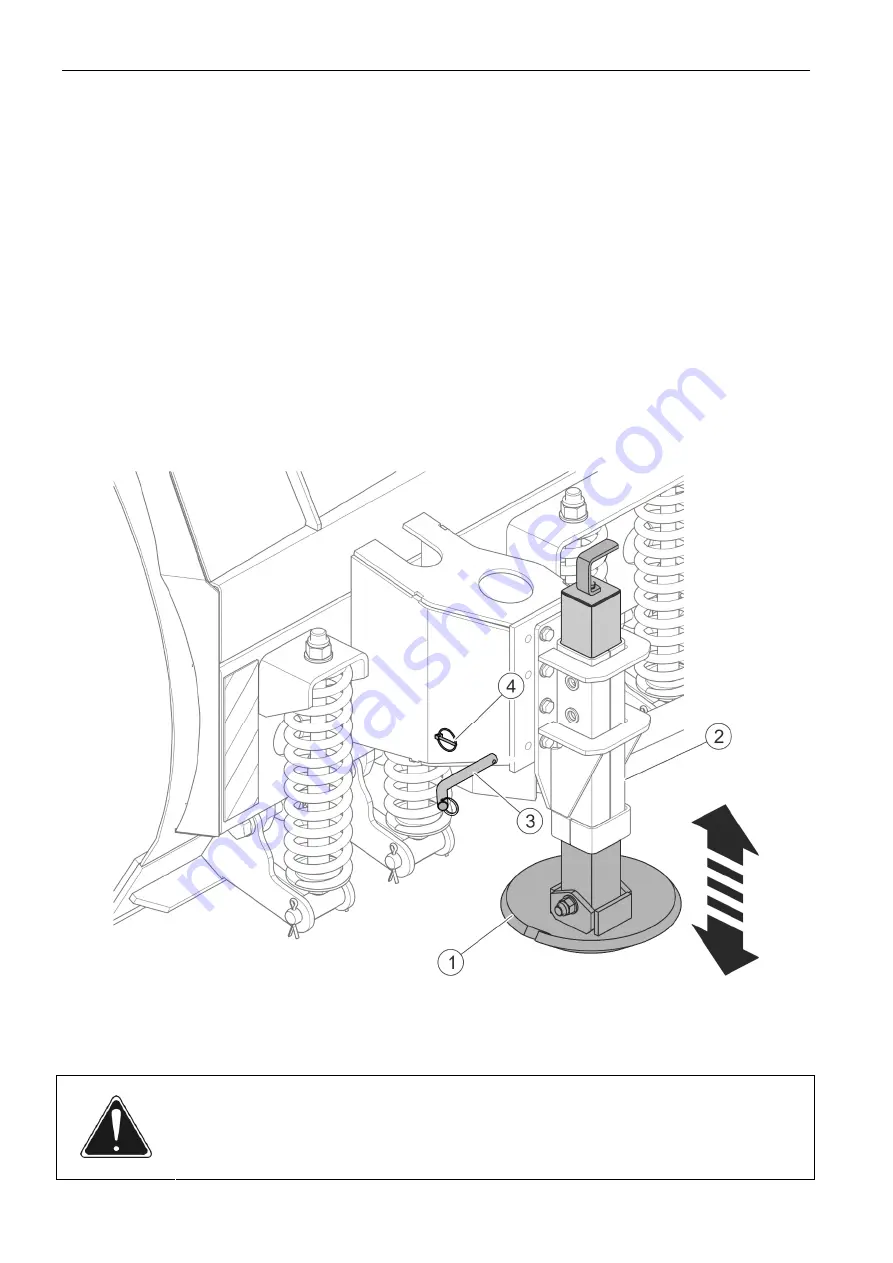

4.4.3 SETTING WORKING HEIGHT

The slides or wheels are used in order to maintain a proper distance between the ground and

collecting blades, to reduce thickness of scraped material layer and to limit the depth of blade

sinking into soft ground.

In the snow ploughs equipped with slides (FIGURE 4.9), the height adjustment is performed

by unlocking pin (3) and proper sliding out or sliding in slide (1) mounted in guide (2).

Location of the slide in the guide can be changed every 12 mm using one of the two

openings in the guide. When the height is set, the slides must be secured with a pin (3) and

securing cotter pin (4). Slides of the left and right blade should be put forward at the same

height.

FIGURE 4.9

Working height adjustment in the snow ploughs equipped with slides

(1) - slide, (2) - slide guide (3) - pin, (4) - locking cotter pin

DANGER

Setting the working height should be performed only when the engine is stopped, and

the machine is raised and secured.

Summary of Contents for PUV-3600HD

Page 2: ......

Page 3: ...SNOW PLOUGH PRONAR PUV 3600HD PRONAR PUV 4000HD MACHINE IDENTIFICATION TYPE SERIAL NUMBER ...

Page 6: ......

Page 9: ...SECTION 1 BASIC INFORMATION ...

Page 19: ...SECTION 2 SAFETY ADVICE ...

Page 29: ...SECTION 3 DESIGN AND OPERATION ...

Page 38: ...PUV 3600HD PUV 4000HD SECTION 3 3 10 ...

Page 39: ...SECTION 4 CORRECT USE ...

Page 58: ...PUV 3600HD PUV 4000HD SECTION 4 4 20 ...

Page 59: ...SECTION 5 MAINTENANCE ...

Page 82: ...PUV 3600HD PUV 4000HD SECTION 5 5 24 ...

Page 83: ...NOTES ...