SECTION 5

Pronar T285/1

5.19

grease, petrol etc. may cause damage and accelerate the ageing process. Bent lines,

permanently deformed, cut or worn should be replaced.

Visual assessment of system:

•

Conduct inspection of system at the same time as when checking tightness.

IMPORTANT!

Repair, exchange or regeneration of pneumatic system components may only be

performed in a specialised workshop.

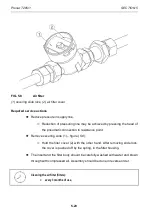

5.3.3 CLEANING THE AIR FILTERS

Depending on trailer working conditions, but not less than once in three months, take out and

clean air filter inserts, which are located in pneumatic system connection lines. Inserts are

used many times and are not subject to changing unless they are mechanically damaged.

DANGER

Before proceeding to dismantle filter, reduce pressure in supply line. While disengaging

filter slide gate, hold cover with other hand. Stand away from filter cover vertical direction.

Summary of Contents for T285/1

Page 2: ......

Page 6: ......

Page 11: ...SECTION 1 BASIC INFORMATION ...

Page 26: ...Pronar T285 1 SECTION 1 1 16 ...

Page 27: ...SECTION 2 SAFETY ADVICE ...

Page 42: ...Pronar T285 1 SECTION 2 2 16 ...

Page 43: ...SECTION 3 DESIGN AND OPERATING PRINCIPLE ...

Page 64: ...Pronar T285 1 SECTION 3 3 22 ...

Page 65: ...SECTION 4 CORRECT USE ...

Page 91: ...SECTION 5 MAINTENANCE ...

Page 124: ...Pronar T285 1 SECTION 5 5 34 FIG 5 13 Trailer s lubrication points part 1 ...

Page 125: ...SECTION 5 Pronar T285 1 5 35 FIG 5 14 Trailer s lubrication points part 2 ...

Page 134: ...Pronar T285 1 SECTION 5 5 44 ...

Page 135: ...NOTES ...

Page 136: ......