CHAPTER 5

Pronar T683P

5.39

5.12

TROUBLESHOOTING

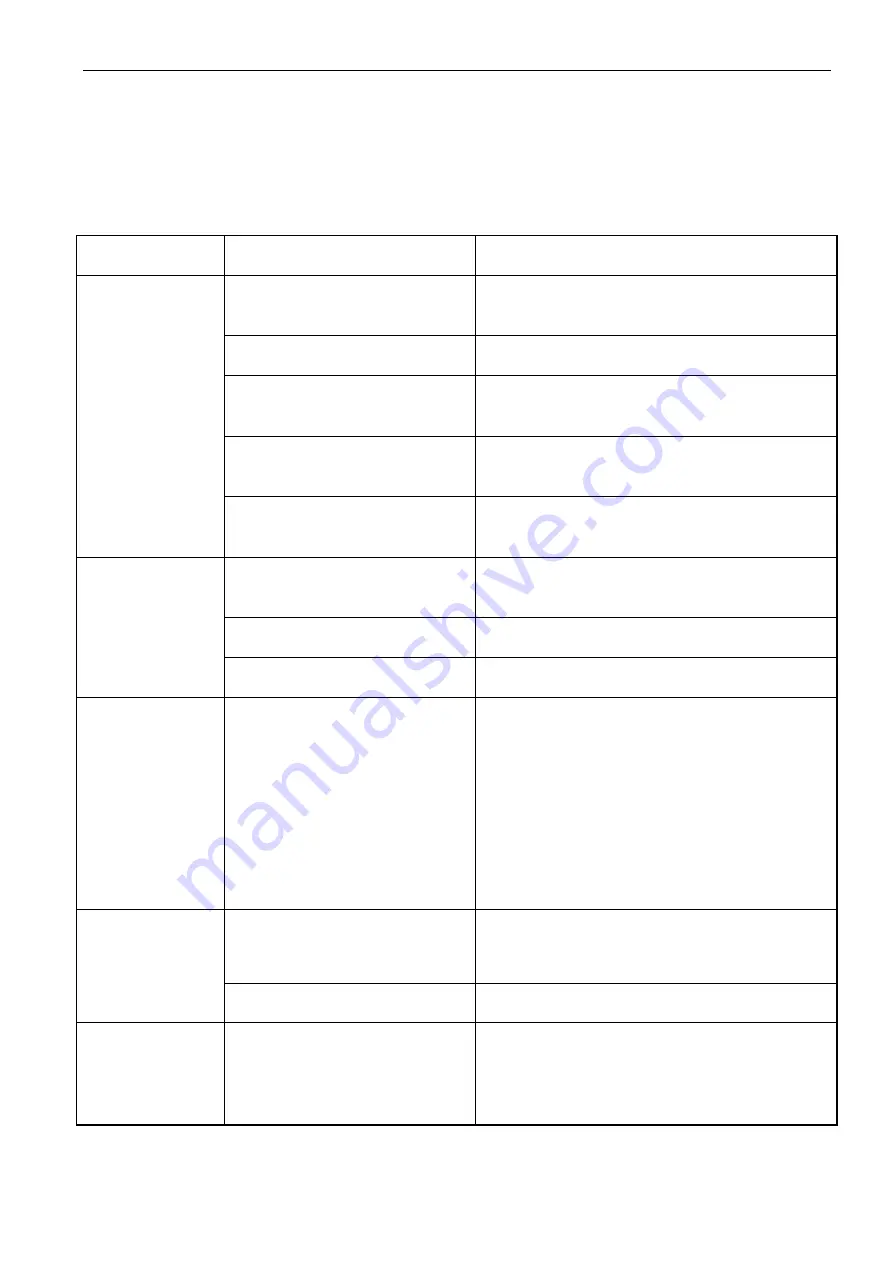

TABLE 5.6.

Faults and how to remove them

FAULT

CAUSE

REMOVAL METHOD

Brake system lines not

connected

Connect the brake lines (applies to

pneumatic system).

Parking brake applied

Release the parking brake.

Pneumatic connection lines

damaged

Replace.

Connection leakage

Tighten, replace washers or sealing sets,

replace hoses.

Trouble with

starting

Defective control valve or

braking force regulator

Check valve, repair or replace.

Excessive bearing looseness

Check the clearance and adjust if

necessary

Damaged bearings

Replace bearings

Noise in the hub

of the axle

Damaged hub components

Replace

Low braking

efficiency

System pressure too low

Check the pressure on the pressure gauge

on the tractor, wait for the compressor to

fill the tank to the required pressure.

Damaged tractor air compressor. Repair or

replace.

Damaged brake valve on the tractor.

Repair or replace.

System leakage. Check systems for leaks.

Incorrectly adjusted service

or parking brake

Adjust expander arm positions

Excessive

heating of the

axle hub

Worn brake pads

Replace brake shoes.

Incorrect

hydraulic

system

operation

Incorrect hydraulic oil

viscosity

Check the oil quality, make sure that the

oils in both machines are of the same

grade. If necessary, change the oil in the

tractor and/or trailer

Summary of Contents for T683P

Page 2: ......

Page 6: ......

Page 11: ...CHAPTER 1 GENERAL ...

Page 25: ...CHAPTER 2 SAFETY OF USE ...

Page 42: ...Pronar T683P CHAPTER 2 2 18 FIGURE 2 3 Arrangement of information and warning stickers ...

Page 43: ...CHAPTER 3 CONSTRUCTION AND PRINCIPLE OF OPERATION ...

Page 62: ...Pronar T683P CHAPTER 3 3 20 ...

Page 63: ...CHAPTER 4 RULES OF USE ...

Page 95: ...CHAPTER 5 TECHNICAL SUPPORT ...

Page 125: ...CHAPTER 5 Pronar T683P 5 31 FIGURE 5 12 Trailer lubrication points part 1 ...

Page 126: ...Pronar T683P CHAPTER 5 5 32 FIGURE 5 13 Trailer lubrication points part 2 ...

Page 135: ...NOTES ...

Page 136: ... ...

Page 138: ......