目次頁

產品介紹

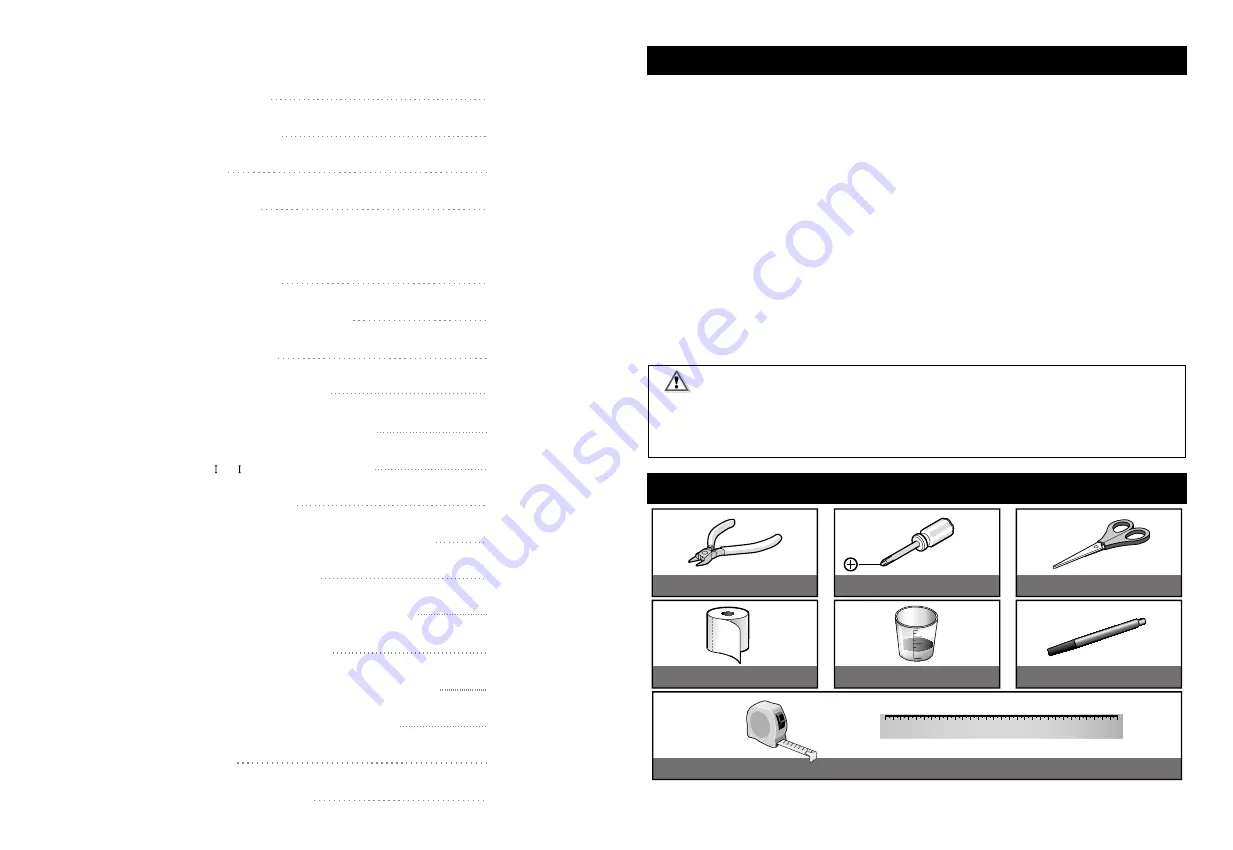

自備工具

零件清單

塑膠模型零件

組裝說明

夾頭組裝

控制盤組裝

手臂組裝

液壓油使用說明

H0~H5

液壓筒組裝

I

1~

I

5

液壓筒組裝

軟管裁切

液壓筒填充說明

軟管與液壓筒組裝

液壓筒模組組裝

操縱桿組裝

控制盤與液壓筒模組組裝

液壓筒與手臂組裝

操作方式

簡易故障排除

P.1

P.1

P.2

P.3

P.6

P.7

P.13

P.20

P.20

P.26

P.35

P.36

P.37

P.37

P.49

P.51

P.66

P.76

P.86

Tools You May Need

Product Introduction

Plastic Parts

Lever Controller Assembly

Mechanical Assembly

Gripper Unit Assemily

H0~H5 Cylinder Assembly

Stand & Control Base Assemily

Main Body Assembly

How To Oil The Parts

How To Cut The Tube

How To Fill Up The Cylinder With Water

How To Fit Tube

Hydraulic Cylinder Module Assembly

1 ~ 5 Cylinder Assembly

Robot Arm Module Assembly

Controller Module Assembly

How To Play

Trouble Shooting

Mechanical

1

0

1

2

3

4

5

6

7

8

9

10 11

12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

CM

or

液 壓 機 器 手 臂

Hydraulic Robot Arm

產 品 介 紹

Product Introduction

With Hydraulic Arm Edge, command six axes of varied movements: the gripper to open and close up to 1.89

inches, wrist rotation of 180 degrees, wrist mobility of 98 degrees, elbow range of 44 degrees, base rotation of

270 degrees, and shoulder motion of 45 degrees. With a vertical reach of 16.35 inches, horizontal reach of 12.42

inches, and lifting capacity of 50g, your robotic friend is ready for your genius to erupt. With the removal of the

gripper, you can activate the suction apparatus. This feature enables the user to elevate objects with a larger

surface area (like a small mobile phone). Another prodigious attribution is a braking system that is integrated in

the lever controllers to execute all commands accurately. WOW!

How does this equate to fun? Your children will have total command and visual manipulation using the science

principles of a Hydraulic system and its application. Easy to follow instructions with detailed graphic illustrations

pave the way for successful and satisfying kit building. Compliment your engineering, math, science, and

technology learning strategy. No battery or motor required. It is powered by water; thus, the “Hydraulic”

significance and how it manipulates axes movement via lever controllers. Hydraulic Arm Edge is recommended

for ages 10 and up, but with its 229 assembly parts, it will challenge the beginner engineering enthusiasts.

自 備 工 具 如 下

Tools You May Need

斜 口 鉗

Diagonal Cutter

剪 刀

Scissors

面 紙

Tissue Paper

十 字 起 子

Screwdriver

杯 子 和 水

Cup & Water

捲 尺 或 尺

Tape Measurer or Ruler

油性麥克筆(細字)

Marker Pen (Fine)

警

告

1.本玩具內含小物件,請勿讓三歲以下孩童取得,以免放入口中造成窒息。

2.兒童使用剪切工具時,請家長指導使用方式,並請在家長監督下使用,以免發生意外。

3.為避免嬰兒或兒童產生窒息的危險,請於拆卸後立即將塑膠袋銷毀或遠離嬰兒及兒童。

Choking hazard - Small parts. Not for children under 3 years.

Adult supervision is recommended when children use scissors.

To avoid danger of suffocation, keep the plastic bag away from babies and children.

Warning

歡迎購買寶工

GE-632

液壓機器手臂。這是一款使用液壓方式操作的玩具,六軸設計液壓手臂可做出多種動

作

:

前端夾具可進行開闔動作,最大開口約

4.6cm

,可旋轉

180

˚

,手腕可上下移動

98

˚

,肘部上下移動

44

˚

,

肩部上下移動

45

˚

,底座可左右旋轉

270

˚

,手臂可上舉的最大高度約

42cm

,水平伸展約

32cm

,可夾舉重量

為

50g

。卸下夾具後,還可使用吸盤裝置,吸盤設計不受物體大小限制,可吸取面積更大的物體。本產品由

229

個零件組成,組裝說明沒有多餘的文字敘述,詳細的圖示就可輕鬆組裝,同時可了解液壓原理,組裝後

可實際操作應用,透過操縱桿使六軸動作配合無間,訓練手眼協調。不須電池、不須馬達、水就可驅動一

切,歡迎工程系列愛好者挑戰本進階模型。推薦

10

歲以上兒童可嘗試獨立組裝,父母在旁陪伴,兒童可從

中得到自我滿足的成就感,同時快樂的享受親子共遊的樂趣。

Summary of Contents for GE-632

Page 1: ...GE 632 Hydraulic Robot Arm...

Page 6: ...8 3 P2 1 1 9 P2 4 5 1 2 1 2 E16 G6 1 1...

Page 9: ...14 4 D2 D3 P2 P2 5 E13 180 1 1 15 6 7 P2 C9 G10 D4 P2x2 1 1 2 E26 Forearm Wrist...

Page 17: ...30 E20 12 14 13 2 2 1 1 P8 C19 Side View PUSH PUSH 31 A7 1 1 2 15...

Page 28: ...52 3 2 3 1 click click click click Push 53 4 5 6 1 2 H0 3 PUSH PULL Cylinder PUSH PUSH...

Page 31: ...58 3 2 1 3 click click click click PUSH PUSH 59 4 5 6 1 2 3 PUSH PULL PUSH PUSH...

Page 34: ...64 3 2 3 1 Click Click Push 65 5 4 6 1 2 3 PUSH PULL PUSH...

Page 37: ...70 10 1 2 Marking 71 2 1 11 12 4 3 Cylinder Ensure the right direction...