2. Be sure the wipe excess material from the top of the acrylic frame

B. Fixture Connections

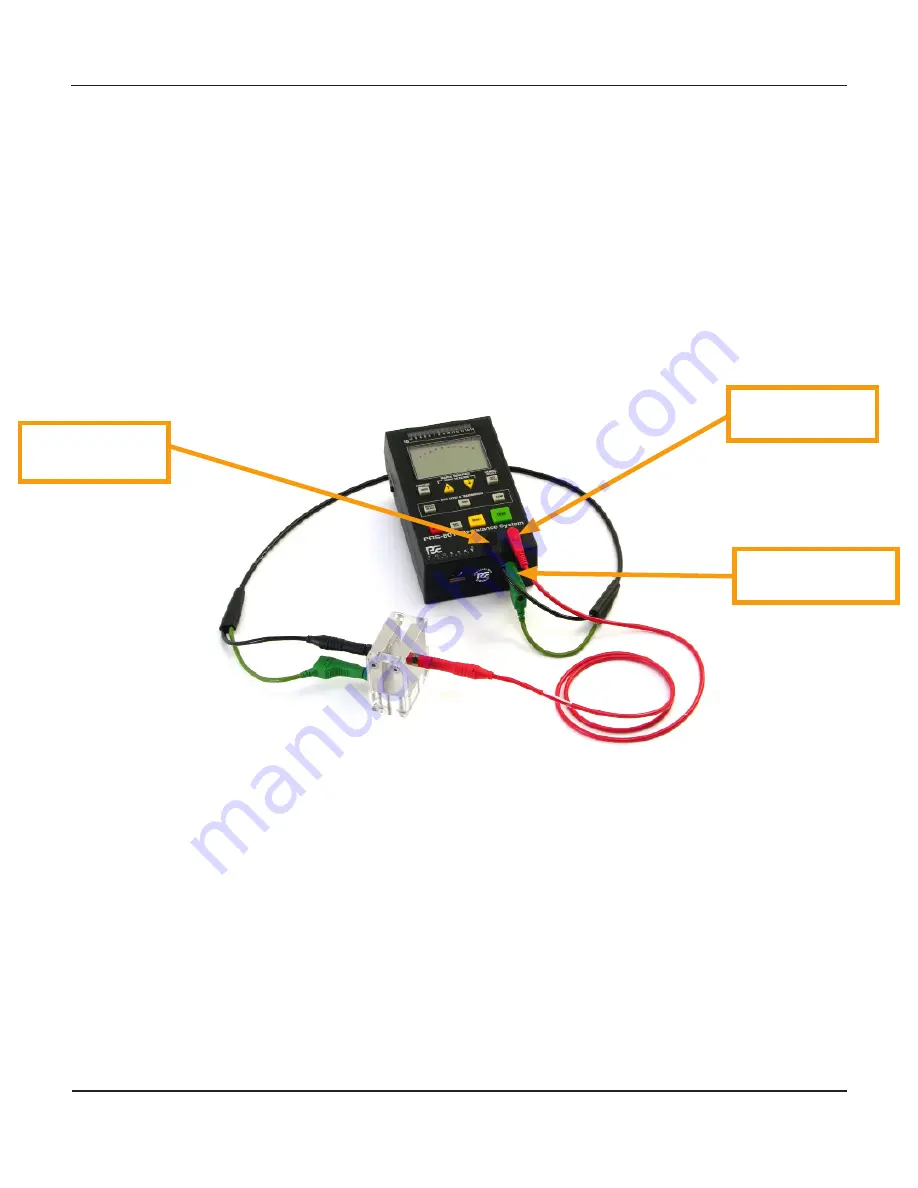

Three connections to a precision, wide range resistance system (Figure 7) are required for accurate

measurements:

1. Connect the instrument’s test voltage (power) lead, usually from the Positive (+) terminal to

the Red connection mounted on the fixture’s power plate.

2. Connect the instrument’s current sensing lead, usually the Negative (-) terminal, to the Black

center plate receptical.

Figure 7: Shielded Lead Set Connections

Negative (-)

Terminal

Instrument Ground

Reference

Positive (+)

Terminal

3. Connect the instrument’s ground reference to the Green guard plate receptical

C. Making the Resistance Measurement

The PRF-930 complies with the fundamental requirements of measuring bulk resistance of pow-

dered and granulated materials. Actual procedures and specified conditions may vary between

test methods cited by standards bodies in different countries. The PRF-930 was designed in accor-

dance with the Recommended Practice for Protection against Hazard arising out of Static Electric-

ity in General Industrie, published by The National Institute of Industrial Safety, Japan, Technical

Recommendation No. RIIS-TR-87-1. Other national committees may be examining similar methods

for these measurements.

Center Plate

Connection

Guard Plate

Connection

Power Plate

Connection

8

Rev. A / January 2010

PRF-930 Advanced Powder Fixture