INSTALLATION

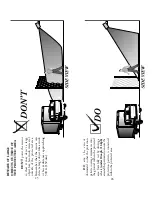

MOUNTING PIRAMID XL2

1. The PIRAMID XL2 comes equipped with a wall

mount bracket. Install the wall mount bracket

where the sensor will be located. Ensure that it is

firmly mounted and free from extreme vibration.

Avoid visual obstructions that may block the

sensor’s field of view.

UNIVERSAL POLE MOUNT

2. For a pole mount installation, PROTECH

offers two universal pole mounts as accessory

items. Model PH-4 is suitable for poles with a

diameter of 1

1

/

2

” to 4

1

/

2

”(3.8cm to 11.4cm). Model

PH-4A is suitable for poles with a diameter of

4

1

/

2

” to 8

1

/

2

” (11.4cm to 21.6cm). The wall mount

bracket mounts to the PH-4/PH-4A Universal Pole

Mount.

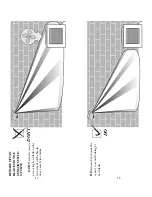

BEST MOUNTING LOCATION

3. The sensor should be mounted so that the most likely

direction of travel by the intruder is toward or away

from the sensor.

4. PIRAMID XL2 provides good transverse detection

capability only when adjusted in the higher sensitivity

settings (10, 9 and 8). Operating the sensor in these

higher settings may increase nuisance alarms. Therefore,

to enable effective detection in the lower sensitivity

settings (1, 2, 3, etc.), it is best to locate the sensor to

detect approaching and receding movement.

5. Remove the Microwave Electronic Assembly from

the Housing/Shroud Assembly by loosening the four

screws on the sensor’s faceplate. Attach the housing/

shroud assembly to the mounting bracket using the

hex head bolt provided.

MOUNTING HEIGHT

6. The optimum mounting height of the sensor can vary

considerably depending on the model’s lens module,

security requirement and environmental conditions.

Refer to the table below for recommended

mounting heights.

LENS

MODULE

LENS

DESCRIPTION

MOUNTING

HEIGHT

Sensor Mounting Height Based On Lens Module Selection

3

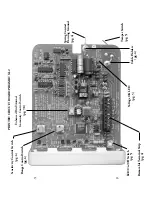

WIRING AND PRELIMINARY

SET-UP

MINIMUM WIRE SIZE:

1. With the housing/shroud assembly attached to the

mounting bracket, feed the wire through the conduit

connector into the sensor housing. For power

connections, PROTECH recommends a minimum 18

AWG wire for wire runs greater than 50 ft (15.5m).

2. Remove terminal strip from the microwave electronic

assembly and wire according to the diagram below.

REMOVABLE TERMINAL STRIP

3. Observe the correct polarity at the power terminals.

SHIELDED CABLE RECOMMENDED

4. For best shielding from Radio Frequency Interference

(RFI) and transients due to lightning or electrostatic

discharge, PROTECH highly recommends the use of

shielded cable. When shielded cable is used, the cable

shield (and/or drain wire) should be connected to

Terminal 1 (HOUS’G GND) at each sensor. Terminal

1 is connected by a

spring contact

to the housing, but

is not otherwise connected to the electronic circuitry.

The other end of the shield should be connected to

a common ground (generally the same ground used

for the power supply or control unit). Regardless of

the type of cable used, Terminal 1 (HOUS’G GND)

should always be connected to a good earth ground.

CABLE HOLDERS

5. After wiring the removable terminal strip, plug it

back into the Microwave Electronic Assembly. Route

cable under “cable holders” which are provided on

the circuit board.

9

8 7

6 5 4 3 2

1

NC

NO

NC

Hous’g

Tamper

Alarm Contacts

GND

+ -

12 VDC

4

LENS-A

Wide Angle – Standard

8-15 ft. / 2.4-4.6m

LENS-B

Medium Angle – Standard

8-12 ft. / 2.4-3.7m

LENS-C

Long Narrow – Standard

7-9 ft. / 2-2.7m

LENS-A-PET Wide Angle – Pet Alley

4-6 ft. / 1.2-2m

LENS-B-PET Medium Angle – Pet Alley

4-6 ft. / 1.2-2m

LENS-C-PET Long Narrow – Pet Alley

4-6 ft. / 1.2-2m