15

S-PARK

- rev.1.1_06_2020

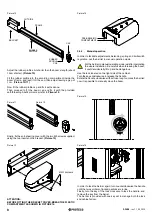

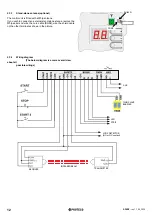

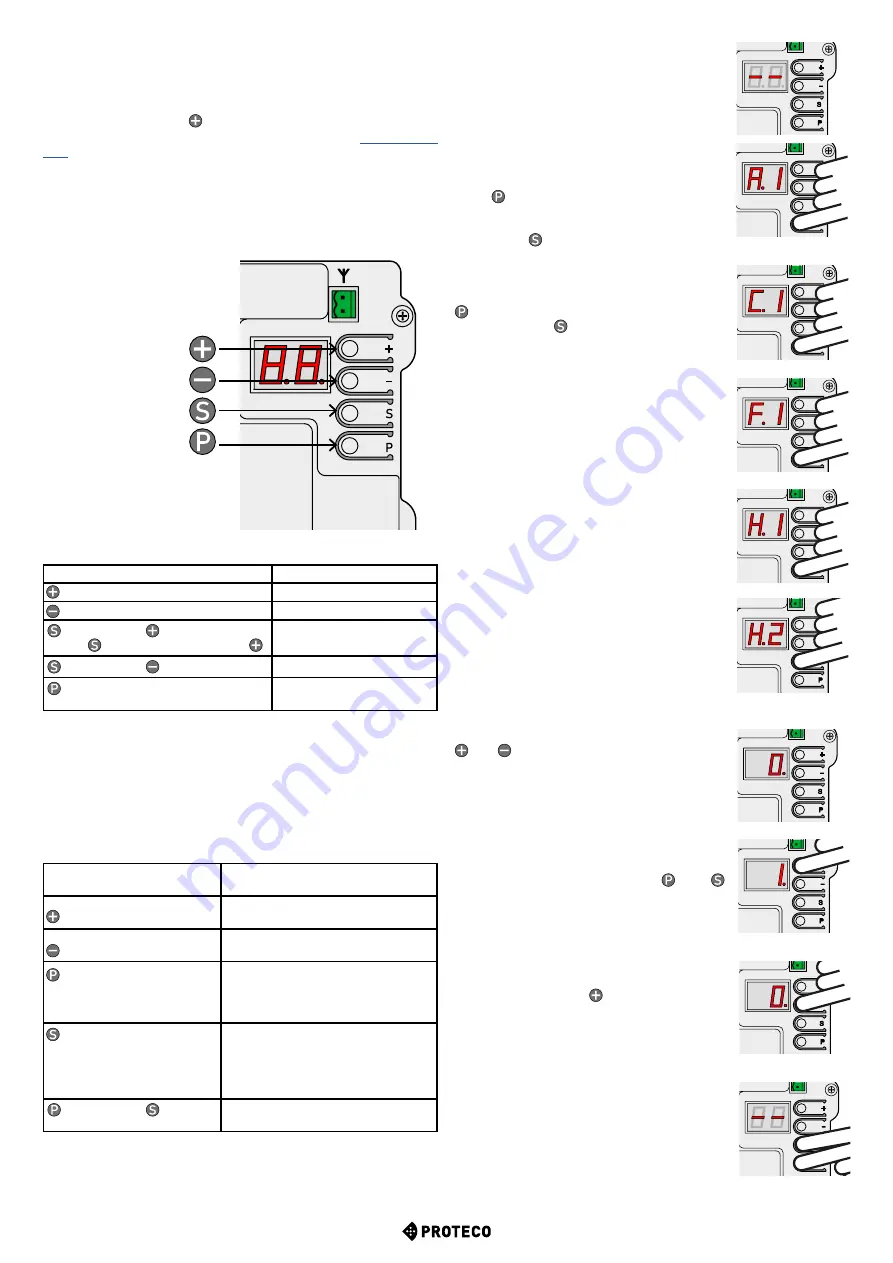

Keys (OPERATION MODE)

Functions

START pulse

START2 pedestrian pulse

together with

(press and while holding press )

Opening command

together with

Closing command

(hold it pressed for short seconds) Programming menu: the

display shows

A.1

4.1.3

Programming keys

Pressing any key during operation the barrier stops.

With an exception for key : if pressed during countdown the barrier

starts immediately working again, refer to Chapter

e

p. 14.

When barrier is in still mode, the display may show “- -” flashing, or

just “- “ if energy save is on and in this circumstance it is possible

to handle the following service keys and functions:

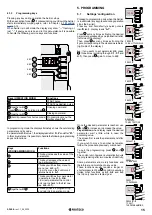

KEY

KEY

KEY

KEY

In programming mode the display alternately shows the outstanding

parameter and its value.

Ex.: parameter

H.2

/ value 1, the display reads first “

H.2

” and after “

01.

”.

In this circumstance it is possible to handle the following programming

keys and functions:

Keys

(PROGRAMMING MODE)

Functions

This key increases the value of the

parameter.

This key decreases the value of

the parameter till 0

This key switches from menu to

menu (ex.

H.3 - J.1

).

From U.x menu the control unit

returns back to

A.1.

This key switches from parameter

to parameter (ex.

H.3 - H.4

).

From last parameter the control

unit returns back to the first one

(ex.

H.6 - H.1

).

together with

This key quits the programming

and returns to operation mode.

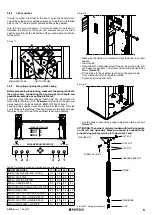

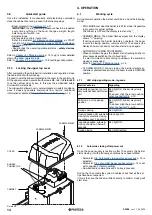

5. PROGRAMMING

5.1

Settings’ configuration

Proceed to programming only when the barrier

is in still mode (any key pressed during operation

stops the barrier).

Press key and hold shortly (a quick pulse is

insufficient): display reads “

A.1

”.

Press

as many times as finding the desired

parameter expressed by an alphabetical letter

(left side of the display).

Then press

as many times as finding the

figure corresponding to the desired parameter

(right side of the display).

Ex.: if you wisht to set parameter

H2

, press

three times (scrolling through

C.1, F.1

and

H.1

), then press again to move to

H.2

.

Once the desired parameter is reached, use

and to increase or decrease the value.

Pay attention

: when display reads the desired

parameter, wait a little while to read the

according value.

The screen first reads the parameter and after

its value.

If you wish to move to another parameter,

follow the procedure previously mentioned.

To quit the programming press and

together.

The control unit, however, automatically quits

the programming after two minutes of inactivity.

Some parameters are merely functions and

therefore are not matched to any value.

These functions usually require a longer or

shorter pressure of key

to confirm execution.

Unlike other functions as

A.1, A.2

and

A.3

that do only require a radio signal.

PRESS

P

FOR A LITTLE WHILE

PRESS

P

PRESS

P

PRESS

P

PRESS

S

TO SWITCH

TO NEXT SETTING

DEFAULT

0

PRESS

+

TO INCREASE

PRESS

-

TO DECREASE

PRESS

S - P

TO QUIT

THE PROGRAMMING