18

S-PARK

- rev. 1.1_06_2020

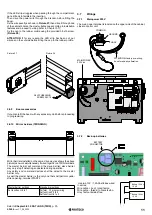

C.5 Working logic configuration

It is possible to set 3 different working logics:

C.5

Working logic

0

(default)

SEQUENTIAL

Every START command stops or reverts the working

cycle according to the sequence:

OPEN – STOP –

CLOSE – OPEN ...

1

PRIORITY TO OPENING

Every START command gives priority to opening; boom

automatically closes according to the time set (refer to

L.1 Automatic closing

)

2

STEP BY STEP

START terminal commands the opening; START2 terminal

commands the closing.

Automatic closing activates if configurated, refer to

L.1

Automatic closing

and

L.2 Automatic closing

pedestrian opening

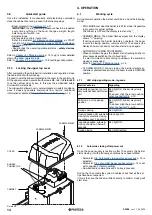

5.3.3

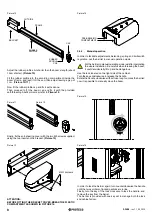

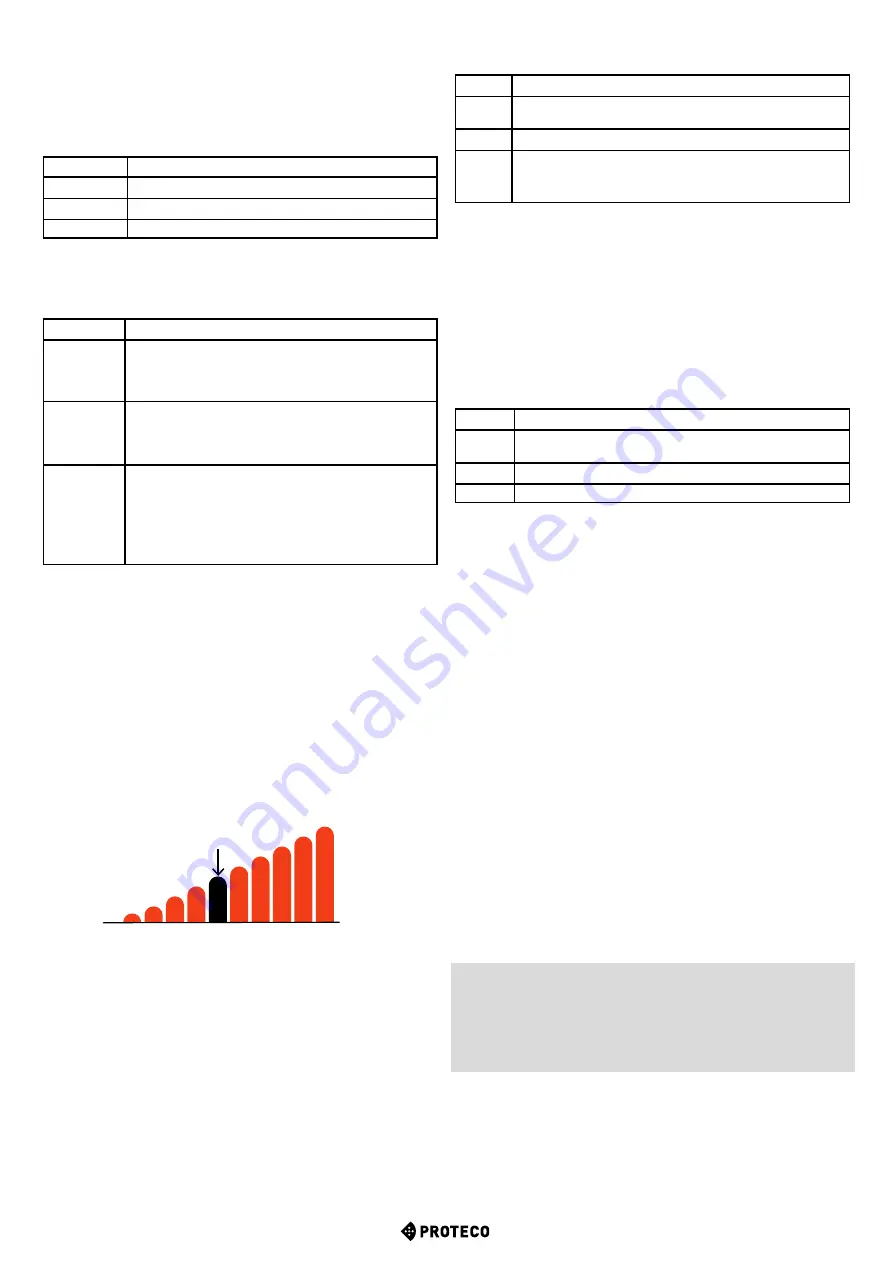

F. Torque

F.1 Obstacle detection

Obstacle detection is a safety feature that complies with outstanding

regulations and makes the barrier area more protected and safer.

If during operation any speed alteration or sudden stress are

detected, the barrier stops in order to avoid or limit damages to

persons or objects.

This feature can be adjusted on different sensitivity levels:

0 = detection is OFF while 10 = maximum detection sensitivity;

factory value (default) is set to 5.

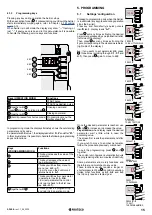

H.3

“Follow me” closing - Functions

0

(default)

The function is OFF.

The barrier closes according to the automatic closing time set up.

1

The barrier closes 2 seconds after completing the opening.

2 ... 10 The barrier closes according to the delay time set, from 2 to 10

seconds when photocell beam is cut and before the opening

is completed.

H.4 Automatic closing after power cut

If you set H.4 to 1, in case of power cut the barrier will close 15

seconds after power is restored.

This function can be activated only if conditions included in chapter

4.1.2 Automatic closing after power cut

, p. 14 are applied.

The factory setting is 1 (default).

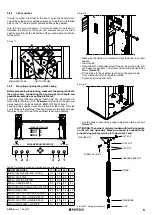

H.6 Master/slave barrier configuration

This parameter allows to set up TWINNING feature in case of a

double barrier installation (mirror barriers).

H.6

Master/slave (TWINNING)

0

(default)

TWINNING OFF

1

Set 1 to configurate the master barrier

2

Set 2 to configurate the slave barrier

5.3.5

L. Working times

L.1 Automatic closing

This parameter sets the automatic closing time, adjustable from 0 =

automatic closing OFF to 99 seconds.

L.2 Automatic closing (pedestrian opening)

This parameter sets the automatic closing time for pedestrian opening,

adjustable from 0 = automatic closing OFF to 99 seconds.

L.1

and

L.2

are totally independent one to the other: they can be set

up in different ways with different times, as well

L.1

can be ON while

L.2

can be switched OFF, and viceversa.

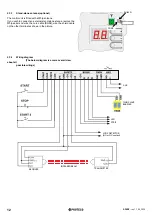

5.3.6

P. SAFETY

P.1 STOP

The factory setting is 0 = output OFF.

If you wish to connect a stop device, set

P.1

to 1position.

P.2 (closing photocell)

When

P.2

is set to 0 = output OFF

It is highly recommended to set

P.2

to:

1 = closing photocell ON (photocell test is OFF)

or

2 = closing photocell ON (photocell test is ON)

The photocell test is a safety provision that helps detecting a faulty

or unsafety photocell.

The test works as follows: before closing, the control unit switches

the power off from TX photocell terminal, in this way the photocell

has no other option but to open the contact.

If the contact doesn’t open in short time, it means the photocell is

faulty and the barrier remains still.

5.3.4

H. SPECIAL FUNCTIONS

H.1 Pre-blinking in closing

Pre-blinking feature warns the user that closing will start soon.

Receiving a start command the blinker starts flashing during a few

seconds before boom starts closing.

Pre-blinking time is adjustable, from 0 to 8 seconds.

H.2 Fixed-light blinker

If you wish to switch the blinker to fixed-light mode, set H.2 to 1.

H.3 “Follow me” closing

This function allows the barrier to immediately close after cutting

the photocell beam.

C.4

Boom configuration

0

RH barrier

1

LH barrier

2 (default)

No configuration is set

C.4 LH and RH boom configuration

This parameter shows the boom opening direction or the boom

position.

Looking from inside the property (cabinet’s door inside the property)

and boom in horizontal position, values are intended as follows:

MIN. 0

1 2 3 4

5

6 7 8 9

10 MAX.

DEFAULT