20

S-PARK

- rev. 1.1_06_2020

U.5 Installation date

This feature allows to load the installation date.

The display will show the installation date in 3 different steps: the

first figure shown is the day (from 1 to 31); pressing

the month

shows up (from 1 to 12); pressing again the year shows up with

two dots.

Pressing the sequence START.

EX.: if your installation date is 14-03-2019 the sequence displayed

will be:

14.

03

1.9.

If you wish to set installation date, press together and holding

during 4 seconds; screen will read “d”, use or to load the day,

from 1 to 31; save pressing .

Screen will read “n”, use or to load the month, from 1 to 12;

save pressing .

Screen wil read “Y”, use or to load the year. Save pressing .

Installation date loading completed.

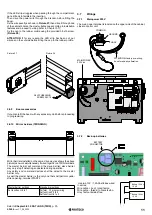

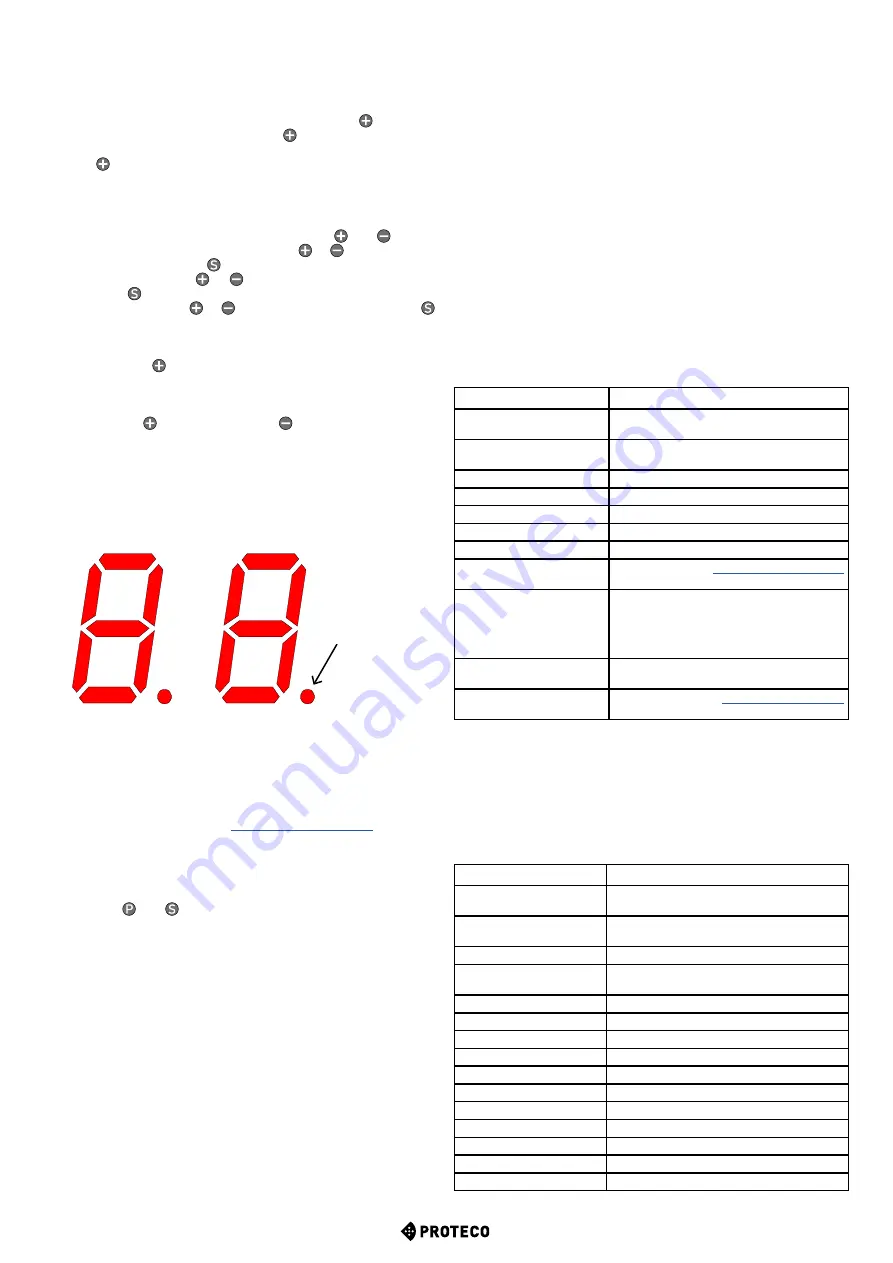

U.6 Trouble shooting and “dead man” functions

Set U.6 and press

to confirm.

This feature allows to display the status of all inputs and at the same

time allows to command direct the boom in “dead man” mode (key

permanently pressed).

Press (and hold) to lift the boom and to lower it.

Release the key to stop the boom.

Attention:

during all these operations,

safety devices are not

working, be carefull.

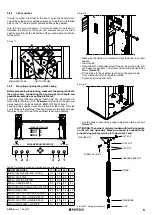

The screen displayes the status of every single input, everyone iden-

tified by a symbol.

If the input is “active” the according symbol will be lit.

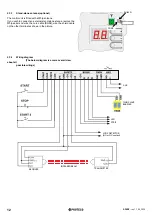

START, STRT2 (LH symbol), when lit the input is active; Radio dot

lights up when receiving a radio signal, saved or unknown.

PH, LD (RH symbol), when lit the input is not active (safety contact

impeeds the operation).

CABINET, when lit the cabinet’s door is not closed.

If one of the

P.

p. 18), the

screen will not show any status (symbol permanently switched off).

The red dot on the right remains permanently lit to confirm

programming is ON.

To quit press and together.

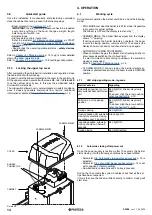

6. DISPLAY

The display shows the barrier status.

If no key is pressed, after 8 hours the display switches off; shortly

press any key to light the display up.

As soon as control unit is powered, the display reads “

8.8.

” (all segments

are lit so as to detect a possible fault).

After that the display reads firmware version (ex. “

1.0

”, or “

2.3

” and

similars).

If control unit is brand new and no programming has been carried

out yet, the display reads “

EE

” for a half second.

As last step, control unit goes to STAND-BY mode and display reads

“

--

” flashing.

The remaining messages are listed in the below table.

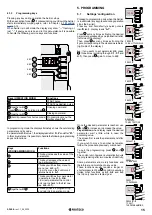

6.1 Messages

During normal operation messages may show up.

Refer to the below table indicating possible messages and according

meaning:

Messages

Meaning

Vertical segments that move

from center outwards

The barrier is opening

Vertical segments that move

from center inwards

The barrier is closing

-S

(start)

Receiving a START command

-P

(start2 / parziale)

Receiving a START2 command (pedestrian)

-H

(halt / stop)

Receiving a STOP pulse

CO

(case open)

Cabinet’s door opened

PC

(photo close)

Closing photocell is working

Ld

(loop detector)

Loop detector LD (

p. 13) is detecting a vehicle

Pair of figures (ex. 02)

Receiving a radio signal by a saved remote

control (remote control saved on radio

position 2).

Usually S or -P show up to confirm which

kind of remote control has been used.

-C

A timer has been wired to START or START2,

automatic closing is stopped

-L

Permanent LD signal (

p. 13) that stops automatic closing

6.2 Faults

The display shows faults and anomalies that may stop the barrier

operation: the fault message is coded with two “dots” matched to

figures or letters.

Refer to the below table:

DISPLAY message

FAULT

oE

(encoder)

Obstacle detected due to a sudden slow run

of the barrier.

oA

(amperometric)

Obstacle detected due to a sudden motor

absortion increase

o5

(standstill)

Obstacle detected due to motor standstill

oC

(voltage overcharge)

Obstacle detected due to motor voltage

overcharge (max. limit rate)

Ld

(loop detector)

Loop detector operating

PC

(photo close)

Closing photocell operating

AH

(abort halt/stop)

STOP pulse

AC

(abort cabinet)

Cabinet’s door is opened

AU

(abort user)

Operation interrupted using onboard keys

FC

(photocell test failed)

Photocell test detected a faulty photocell

EC

(over current)

Motor absorbs too much current

EY

(overheating)

Component overheating

EF

(start fail)

Barrier fails to start

EU

(timeout)

Time exceeded

EN

(encoder wiring)

Motor and/or encoder are not properly wired

START

START2

STOP

RADIO

DOT

PERMANENTLY

LIT

CABINET

PH

LD