1. Safety Information

The following safety informations and all advices in this manual eventually have to be

extended with the local safety standards which are valid at the installation site of this

machine.

Before each use this machine have to be visually inspected! Check the following points:

- Density of all hydraulic components (pump, cylinder, tube and all hydraulic connec-

tors)

- Frame is in good condition (no crack, bent or broken parts)

- No loose screws and nuts in sight

• Always wear safety helmet, face shield, hand gloves, saftey shoes and additional personal

safety equipment to prevent workplace accidents.

• Some parts being pressed may have a tendency to pop out of the press or explode un-

derpressure. Protect yourself accordingly. Keep hands away from the pressure head and

out of support rod holes. This press is designed for pressing, bending, and straightening

purposes only. DO NOT compress springs or other objects that could be ejected from the

press. DO NOT compress objects that could shatter.

• The adjust beam has to be mounted horizontal and must be secured with both pins in all

four mounting holes.

• Always center the work piece on the table plates and center the pressure head on the work

piece to prevent injury by ejection of the work piece.

• Do not operate this press beyond it rated capacity.

• Please understand the max. working stroke before operate, Do not overload the max.

working stroke, so as not to damage parts.

This machine has to be yearly inspected by a technical surveyor for hydraulic compo-

nents. In this survey the following parts has to be inspected:

- All weld joints

- Pump and cylinder bases and sockets

- All hydraulic tubes and hydraulic connectors

2. Specification

Manual self-standing workshop press for assembly or straightening work. Casing is made of

welded quality steel sections. The height of the work table is easy to adjust. Integrated mano-

meter, automatic piston return function.

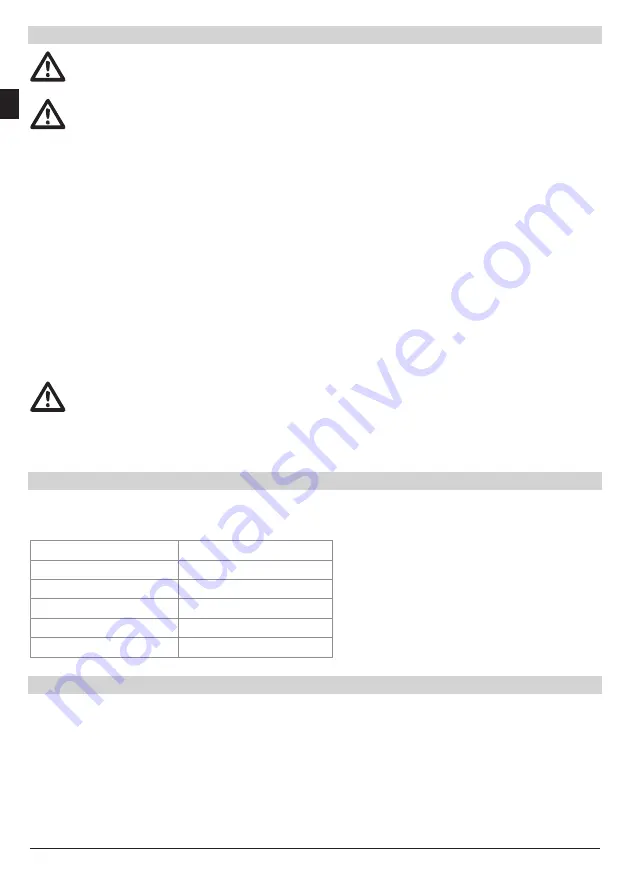

Type

WZWP-020M

Max. Capacity

20t

Working height

0 - 910 mm

Working width

≤ 460 mm

Dimensions WxDxH

845 x 420 x 1.680 mm

Net weight

83 kg

3. Assembly

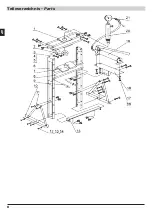

Mount both legs (10) on the poles (6) according schamtics (see page 8). Mount fix plate (15)

and adjust beam (8, only with pins). Mount cross beam (1) and fixed base (18). Finally mount

all hydraulic parts: handle pump (19), cylinder (20), manometer (21) and hydraulic tube.

Fasten alle bolts and nuts after final assembly. Give special attention to fasten all hydraulic

screw-connections.

If the manometer shows in the wrong direction, you can change the angle by using the upper

check nut.

The assembly is completed.

6

EN