SOLID SLABS and WALLS should be considered beams.

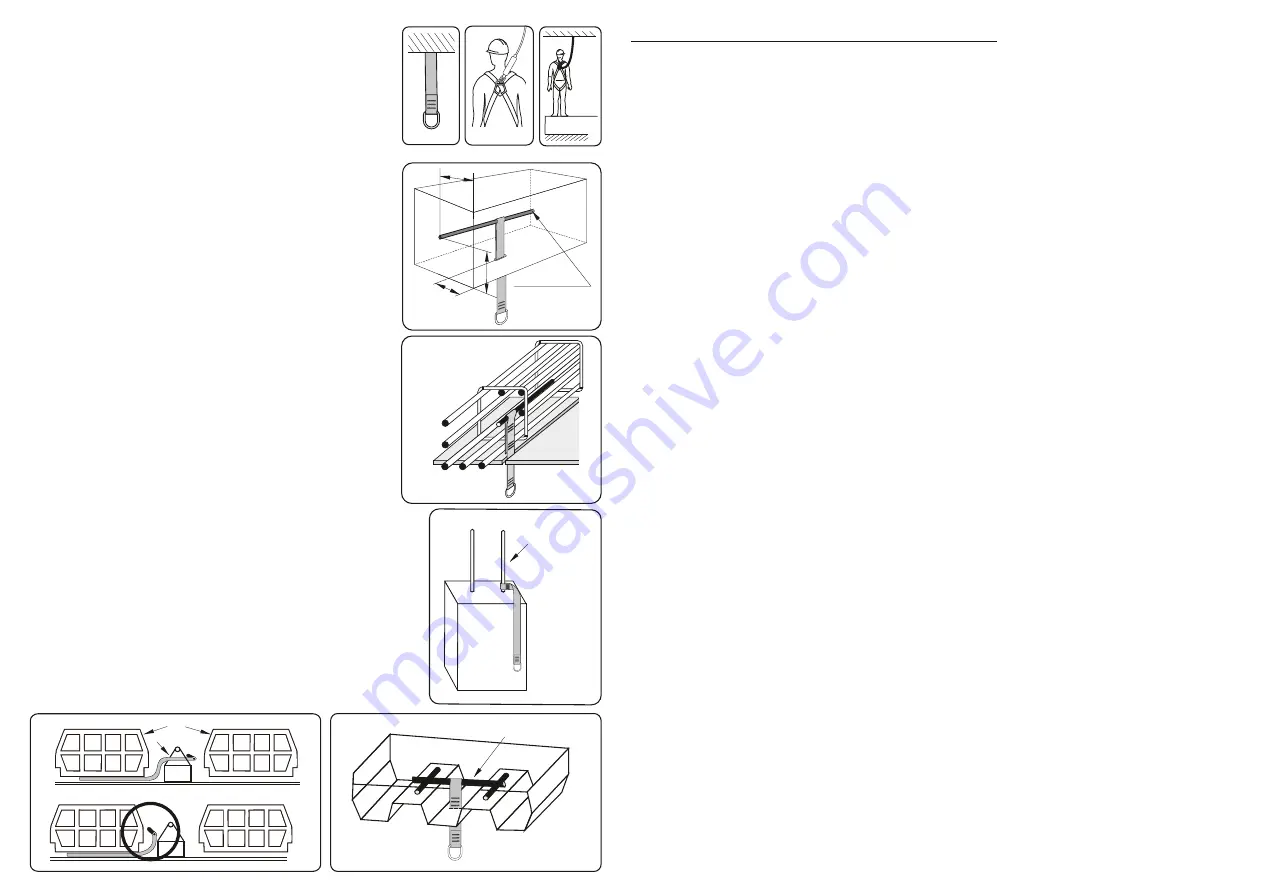

For formwork of CEILINGS, in installation loop of webbing sling insert a steel rod with length of

min. 30cm and diameter of min. 10mm, and place it between truss beam and hollow bricks of

the ceiling (Fig. 6, 7). Attachment D-ring of device AZ 640 should be passed through truss beam

so that the rod in installation loop rests on rods of the beam. The other end with attachment D-

ring should be passed under hollow bricks of the ceiling and left until formwork is removed once

concrete has cured. Only then webbing sling can be used. To remove webbing sling AZ 640 just

use a sharp knife and cut the webbing to the concrete surface.

When planning a point of the device installation, please note that it should be located behind

user operating at the ceiling edge, therefore it is recommended to place the device 1m or 1.5m

from the ceiling edge.

DO NOT USE THE DEVICE UNTIL CONCRETE REACHES A STRENGTH OF 200 kg/cm2!

USER MANUAL

Check whether installation of webbing sling AZ 640 in construction site is consistent with safety and

health protection plan.

Otherwise person responsible for OHS in construction site should be notified on the need to modify

the previously adopted safety and health protection plan.

Before installation check condition of anchor device. In case of any doubt it should be removed

immediately. Webbing should have no losses in its width and thickness. No knots are allowed on

the webbing. Check if the device is provided with registered date of installation and whether

admissible time of usage is not exceeded. All anchor devices with missing label, unregistered date

of installation or exceeded time of usage must be taken out of operation IMMEDIATELY.

Personal fall protection set (connecting and absorbing device) should be connected to a buckle on

webbing sling AZ 640 by means of a connector (Fig. 1, 2, 3).

INSTALLATION INSTRUCTIONS

Anchor device AZ 640 should be installed in concrete with the end on installation loop side. The end

of webbing with attachment D-ring remains outside concrete so that on a later stage, selected

personal fall protection equipment is attached to it. Reinforcing bars should be used as an

attachment point for the loop (Fig. 4.1, 4.2).

On BEAM loops of the device are placed inside the reinforcement at such height so that after

formwork is removed, concrete edges match the double reinforcement area of webbing AZ640

(Fig. 4).

Steel rod with a minimum length of 30cm and minimum diameter of 10mm should be attached to the

reinforcement. Place anchor device AZ 640 between two formwork plates (upper or lower,

depending on availability) which should be slightly separated using a crowbar. Once placed, they

should be left so that formwork returns to its original position. Installation is easier when the above

steps are carried out with use of two formwork plates at the same time. During installation pay

particular attention so as not to damage webbing of the device.

On PILLARS loop of the device is attached directly on reinforcing bar of a pillar of the next ceiling.

Webbing should be attached near the pillar so that after covering the higher ceiling with formwork, it

is located between pillar and formwork (Fig. 5).

rys. 5

rys. 3

rys. 6

Minimum bar diameter 10mm, minimum bar length 300mm.

rys. 1

FORBIDDEN!!!

rys. 7

After the device has been used to arrest a fall from a height, remove the anchor device immediately and

withdraw it from use. Anchor device AZ640 is designed for protection of one person only.

All devices with missing marking or unregistered date of installation must be removed from construction

site IMMEDIATELY. Before webbing sling is used check if the device is in good condition, there are no torn

or missing fibres, threads, stitches). Avoid contact with aggressive substances such as acids.

Recommended work temperatures range from -30ºC to +50ºC. Do not attempt to repair anchor device. If it

has been damaged, remove it immediately. Check whether anchor device is fitted only with certified and

compatible elements of personal protective equipment. Before commissioning check whether installation

is correct.

Therefore load the installed anchor point in the place of attachment of personal fall protection equipment

with a force of 5kN for at least 30 seconds.

Strength of the ground should be min. 15kN.

Truss beam

Hollow bricks of ceiling

Place anchor device

AZ 640 directly

on reinforcing bar

100 mm

100 mm

100 mm

rys. 4.1

Reinforcing bar

-

minimum diameter 10mm

-

minimum length x 300mm.

rys. 4.2

rys. 2

FUNDAMENTAL RULES FOR USING PERSONAL PROTECTIVE EQUIPMENT

!

!

personal protective equipment cannot be used by people whose health condition may influence their safety during everyday use

or emergency procedures.

!

there must be a rescue operation plan which can be used whenever needed.

!

it is forbidden to perform any modifications of the equipment without the written consent of the manufacturer.

!

any repairs of the equipment may be performed only by its manufacturer or an authorised representative of the manufacturer.

!

personal protective equipment must be used in conformity with its operational purpose.

!

personal protective equipment is considered personal equipment and should be used by a single person only.

!

make sure that all elements of the equipment that constitute the fall prevention system are properly mated prior to use. Perform

periodical inspections of connections and mating of equipment in order to avoid unintentional loosening or disconnecting.

!

it is forbidden to use protective equipment if one of its elements is hampered by another during operation.

!

all parts of the fall prevention equipment must be in accordance with appropriate regulations and equipment operational

instructions and binding standards:

- EN 361 for full body harnesses

- EN 353-1, EN 353-2, EN 354, EN 355, EN 360, EN 362 for fall prevention systems

- EN 795 for equipment anchor points (permanent anchor points)

- EN 358 for work positioning systems

!

carry out a careful inspection of personal protective equipment prior to each separate use in order to check its condition and

operation. Inspections must be performed by the user.

!

such inspections should check all equipment elements with particular attention paid to: any defects, excessive wear, corrosion,

points of tearing, cuts and improper operation. Particular attention must also be paid to each individual device:

- full body harnesses and work positioning belts: buckles, adjustment elements, fastening points (snap hooks), slings, seams,

loops;

- energy absorbers: hitch loops, slings, seams, body and connectors;

- lanyards and textile guides: lanyards, thimbles, connectors, adjustment elements, plaits;

- lanyards and steel guides: lanyards, wires, clamps, loops, thimbles, connectors, adjustment elements;

- retractable type fall arresters: lanyards or slings, correct operation of winding mechanism and locking mechanism, body,

shock-absorber, connectors;

- guided type fall arresters: device body and its correct movement along the guide, operation of locking mechanism, rollers,

bolts and rivets, connectors, safety shock-absorber;

- connectors (snap hooks): load-bearing body, riveting, main catch, operation of locking mechanism.

!

personal protective equipment must be withdrawn from use and undergo a complete periodical inspection at least once a year

(after 12 months of use). Periodical inspection must be carried out by a qualified person responsible for periodical inspections of

safety equipment in a given place of work. Periodical inspections must be also carried out by the equipment manufacturer or an

authorised representative of the manufacturer. Such an inspection should check all equipment elements with particular attention

paid to: any defects, excessive wear, corrosion, points of tearing, cuts and improper operation (see the previous point).

!

If protective equipment has a complex structure, for example retractable type fall arresters, periodical inspections should be

carried out only by the equipment manufacturer or its authorised representative. The date of the subsequent inspection shall be

specified after the periodical inspection has been completed.

!

regular periodical inspections are essential in terms of equipment condition and safety of users only fully operational equipment

is able to provide safety.

!

make sure that all labels on protective equipment (elements of this equipment) are legible while performing a periodical

inspection.

!

all information concerning protective equipment (name, serial number, date of purchase and date of first operation, user name,

information concerning repairs and inspections and withdrawal from use) must be included in the Operation Sheet for a particular

device. The factory where equipment is stored is responsible for making entries in the Operation Sheet. The Sheet should be

completed by the person responsible for safety equipment in a given place of work. Equipment without a properly completed

Operation Sheet cannot be used.

!

if equipment is exported to other countries, the provider must equip it with operational and maintenance instructions as well as

information concerning periodical inspections and repairs in the language of the country where the equipment is going to be used.

!

personal protective equipment must be immediately withdrawn from use if there are any doubts concerning its condition or

operational correctness. Equipment can be reused after it has undergone a complete inspection carried out by the manufacturer

and written authorisation for reuse has been issued.

!

if personal protective equipment was used to prevent a fall, it must be withdrawn from use and physically destroyed.

!

a full body harness in accordance with EN 361 is the only accepted device for keeping a body in the personal protective

equipment against falls from a height.

!

fall arresting systems can be connected only to full body harness fastening points (buckles, loops) marked with the capital letter

“A”.

personal protective equipment should be used only by people trained in operating it.