3

2

.

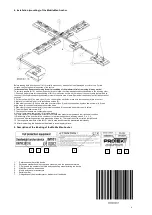

Construction of the Mobile Man Anchor.

-

Spring-loaded anchor point

- 1 piece, enables the connection of individual equipment to the mobile man anchor:

a. safety harness according to EN 361

b. a coupler/energy absorber in the form of:

- lifeline fitted with an energy absorber according to EN 354/355

- self-locking device according to EN 353-2

- self-locking device according to EN 360

- couplers (snap hooks) according to EN 362

-

Unit weight

- 12 pieces, single weight (1 of 12), to be set on the ground, equiped with grip to transmit.

-

Main cross

- 1 piece, cross made of hot deep galvanized steel, it is base for spring-loaded anchor point (set for good),

it is also base for connection (with use of steel connector) with z steel weights.

-

Steel connector

- 4 pieces, connectors enable to connect steel weights with main cross, made of hot-deep galvanized steel.

-

Press down screw

- 12 pieces, protect steel weights from slide down from steel connectors and main cross.

3. Technical data of the Mobile Man Anchor

-

measurements

– according to the drawing below

-

maximum number of people working simultaneously

– 1 person

-

total weight

- 220kg +/- 2kg

-

main structure

– hot galvanized steel

-

main weights

– made of rubber and plastic composit (UV resistant

rubber mixture)

-

connecting elements

– hot galvanized steel

Press down screw

Steel connector

Spring-loaded anchor point

Main cross

Unit weight