Sensor Orientation

For the best results, 500 Series sensors should be mounted with the faceplate in the vertical plane.

Mounting the device with the flow connections uppermost can help eliminate entrained air from your

system.

Flow Direction

The 500 Series Metering Flow Switch is not sensitive to flow direction. Flow can be introduced to the

sensor from either side.

NPT pipe thread connections

Pipe threads seal by making metal-to-metal contact between male and female components.

Consequently they are particularly prone to the damaging effects of galling, which occurs when two

surfaces move against each other under pressure. When installing pipe threads it is essential to use a

high quality lubricating and sealing material.

•

Use Teflon tape or a PTFE-based liquid sealant to provide lubrication for the junction and a leak-tight

connection at both input and output connections. Real-Tuff and Hercules are two of many suitable

brands of PTFE-based sealants.

•

Do not over-tighten the connection. Refer to instructions for installation of the mating fittings for

information on torque requirements.

•

Leak testing of all connections in your flow circuit is recommended. Pressurizing the system with air

and external testing with a dilute soap solution can help identify leaking connections.

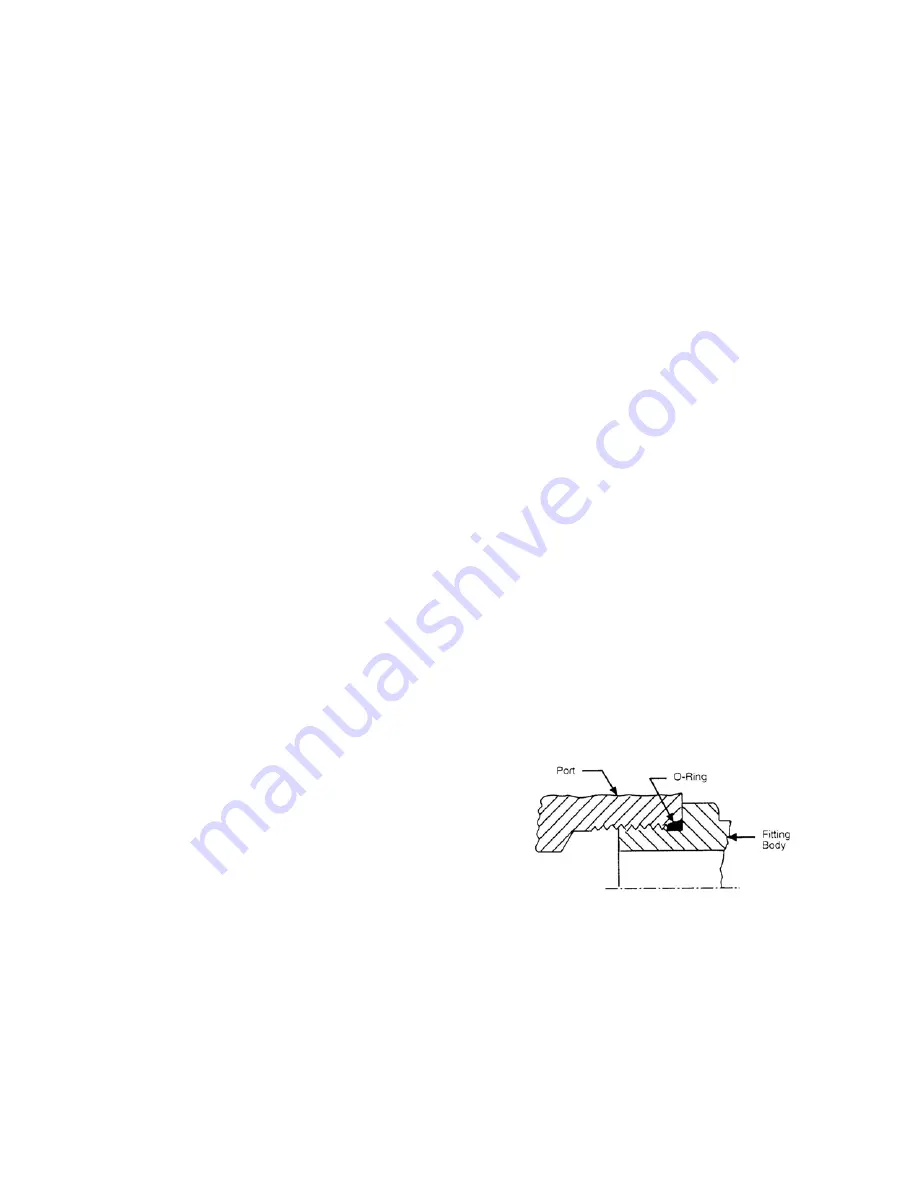

SAE straight thread connections

With these connectors, an O-ring makes the seal while the threads hold the connecting assembly in

place. Straight thread connections should receive a small amount of high-pressure lubricant before

installation to prevent galling.

Non-adjustable fittings

1. Bring the non-adjustable fitting into firm

contact with the face of the port, using a

wrench.

2. Check to be certain that the O-ring fits

easily into the non-threaded receiving

area of the port, and is not pinched.

500TRM-002

Page 10 of 22

March 2007