500TRM-002

Page 9 of 22

March 2007

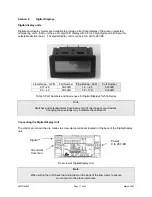

Plumbing Connections

Note

Before connecting a sensor into your fluid line, verify that the normal flow rates expected in that line

are within the operating range of the sensor.

Extended use above the rated maximum flow rate of the sensor will reduce its useable life.

Note

It is recommended that connections to the stainless steel flow sensor be made with stainless steel or

materials of similarly chemical inertness to minimize potential corrosion damage.

Note

The flow response of the sensor, and thus its calibration may be dependent on the internal diameter

(ID) of an incoming pipe, or the ID of a tube connection.

If the ID of your pipe or tube fitting where it connects to the inlet port is LESS than the value shown in

Table 2, calibration values may be invalid.

Appropriate calibration procedures can be applied to allow the 500 Series flow sensor to be used with

pipes and connections with ID’s smaller than those shown in Table 2. Contact Proteus for assistance.

Flow Range

Orifice ID

Model #

GPM LPM

inches

mm

0504SA2

0.1 – 2.0

0.6 – 7.5

0.187

4.76

0504SN2

0.1 – 2.0

0.6 – 7.5

0.187

4.76

0504SA4

0.3 – 4.5

1.2 – 17.0

0.270

6.86

0504SN4

0.3 – 4.5

1.2 – 17.0

0.270

6.86

Table 2: Minimum ID of pipe or connection for calibrations to be valid.

Note

The flow response of 500 Series sensors and thus their calibration may be dependent on the form of the

device attached to the inlet connection and other closely located up-stream devices.

Elbows, T-pieces, valves and filters located immediately up-stream from the flow sensor can introduce

swirling motion to the liquid flow. The swirling motion reduces the linear velocity of the flow stream.

We recommend that a straight run of pipe of more than 10 x pipe ID (~4 inches or 10 cm) be used

between the flow sensor and any up-stream devices to minimize these effects.

Appropriate calibration procedures must be used to provide an accurate flow measurement with elbows

or T-pieces that must be attached directly to the inlet connection.

The 500 Series sensor is typically unaffected by the form or proximity of devices on its downstream side.